Straw briquette gasification dual-swirl burning furnace

A double-swirl and combustion furnace technology, which is applied in the fields of joint combustion mitigation, chemical industry, household stove/stove, etc., can solve problems such as insufficient combustion of gas, low gasification efficiency, and secondary pollution of tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] The specific implementation, non-limiting examples are as follows:

Embodiment

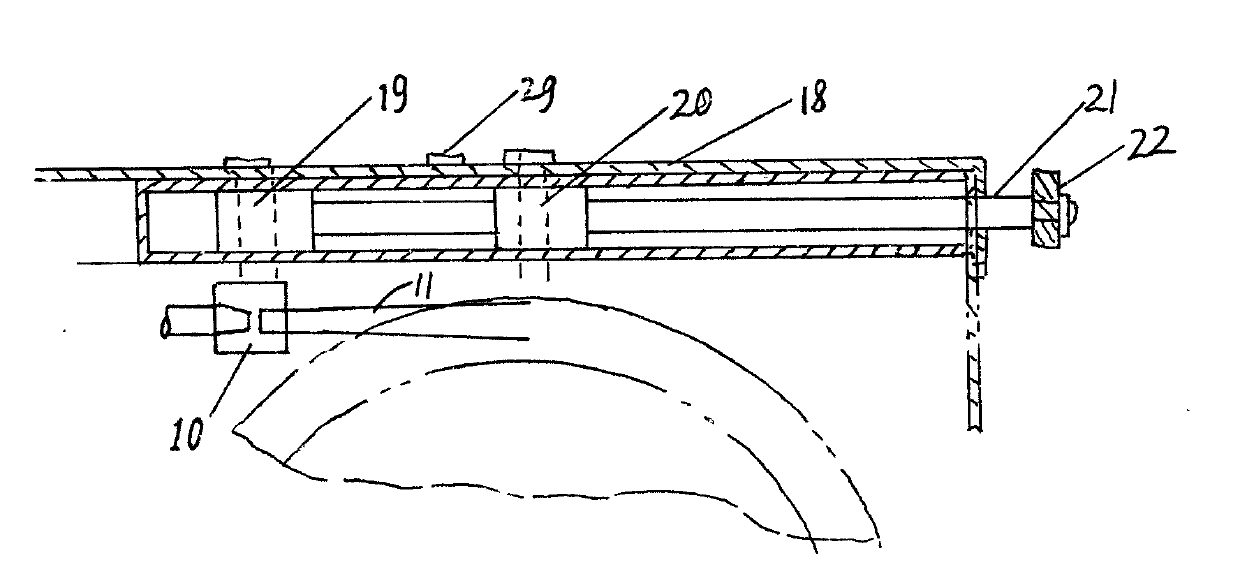

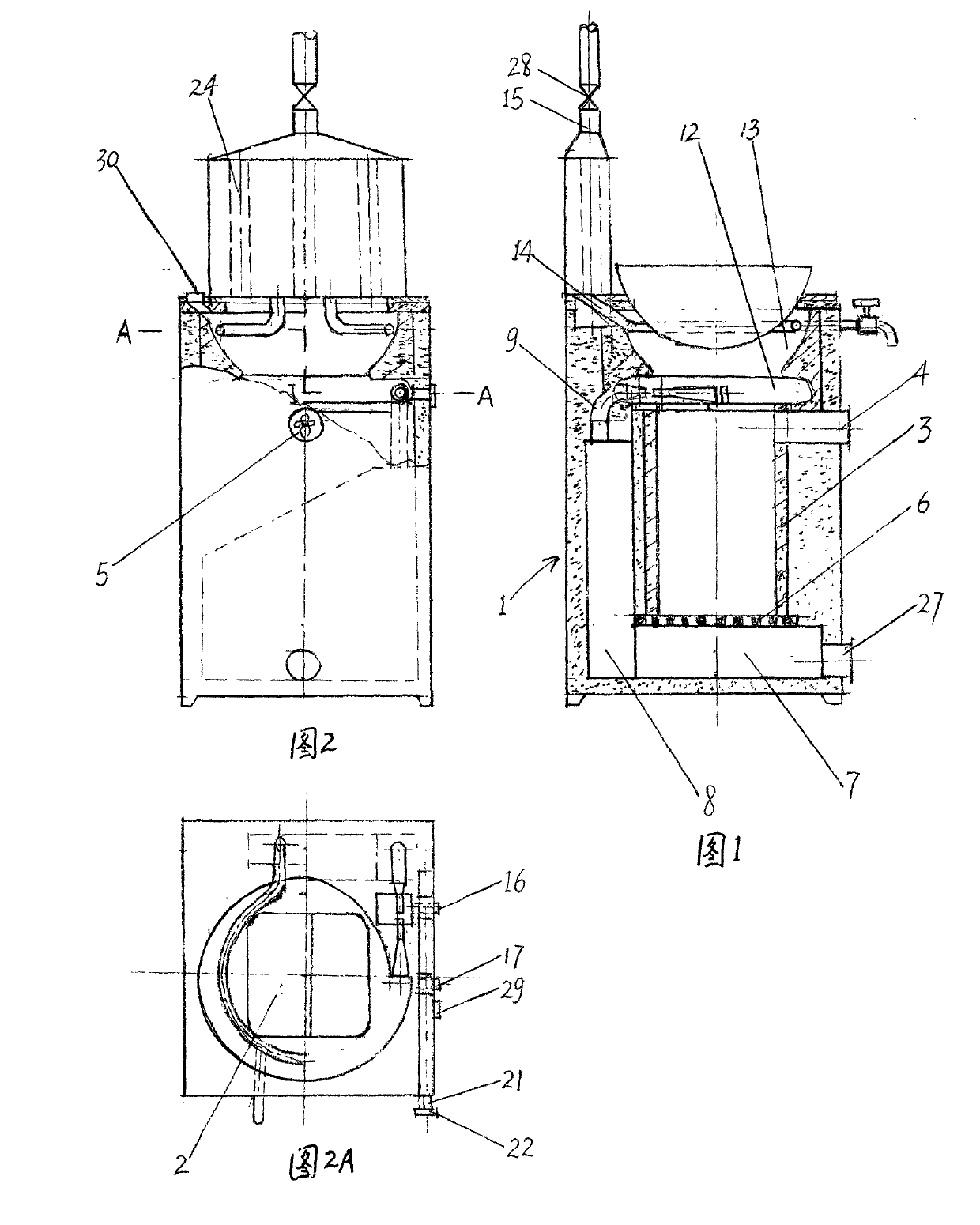

[0020] Example: Combine Figure 1-Figure 2A , the straw briquette gasification double-swirl combustion furnace of this embodiment, the furnace body 1 has an insulating layer and the furnace body is divided into an upper combustion chamber and a lower gasification chamber, and a partition door 2 is used between the combustion chamber and the gasification chamber separated;

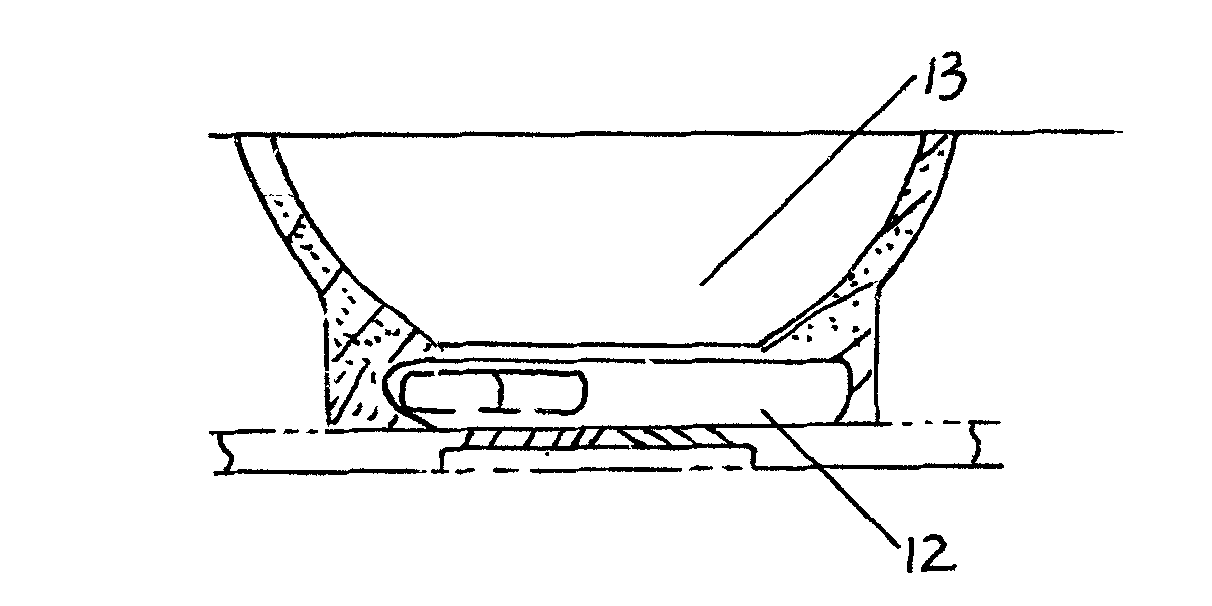

[0021] The gasification chamber includes a furnace chamber 3 located at the lower part of the furnace body, a refill door 4 set on the side of the upper part of the furnace chamber, an adjustable gasification chamber air inlet 5 arranged on the refill door, and a grate below the furnace chamber. 6 and the ash collection pit 7; during the specific setting, the feeding door 4 is an empty pipe, and its end is hinged to a sealing plate, and the sealing plate is provided with a plurality of small holes, and the adjusting knob of the air inlet 5 of the gasification chamber is also opened in one piece. For a pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com