Brewery wastewater treatment device and treatment method

A technology for brewing wastewater and treatment device, which is applied in the fields of food industry wastewater treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. Large fluctuations and other problems, to achieve the effect of improving the effect of wastewater treatment, stable effluent quality, and short treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in more detail below in conjunction with the accompanying drawings:

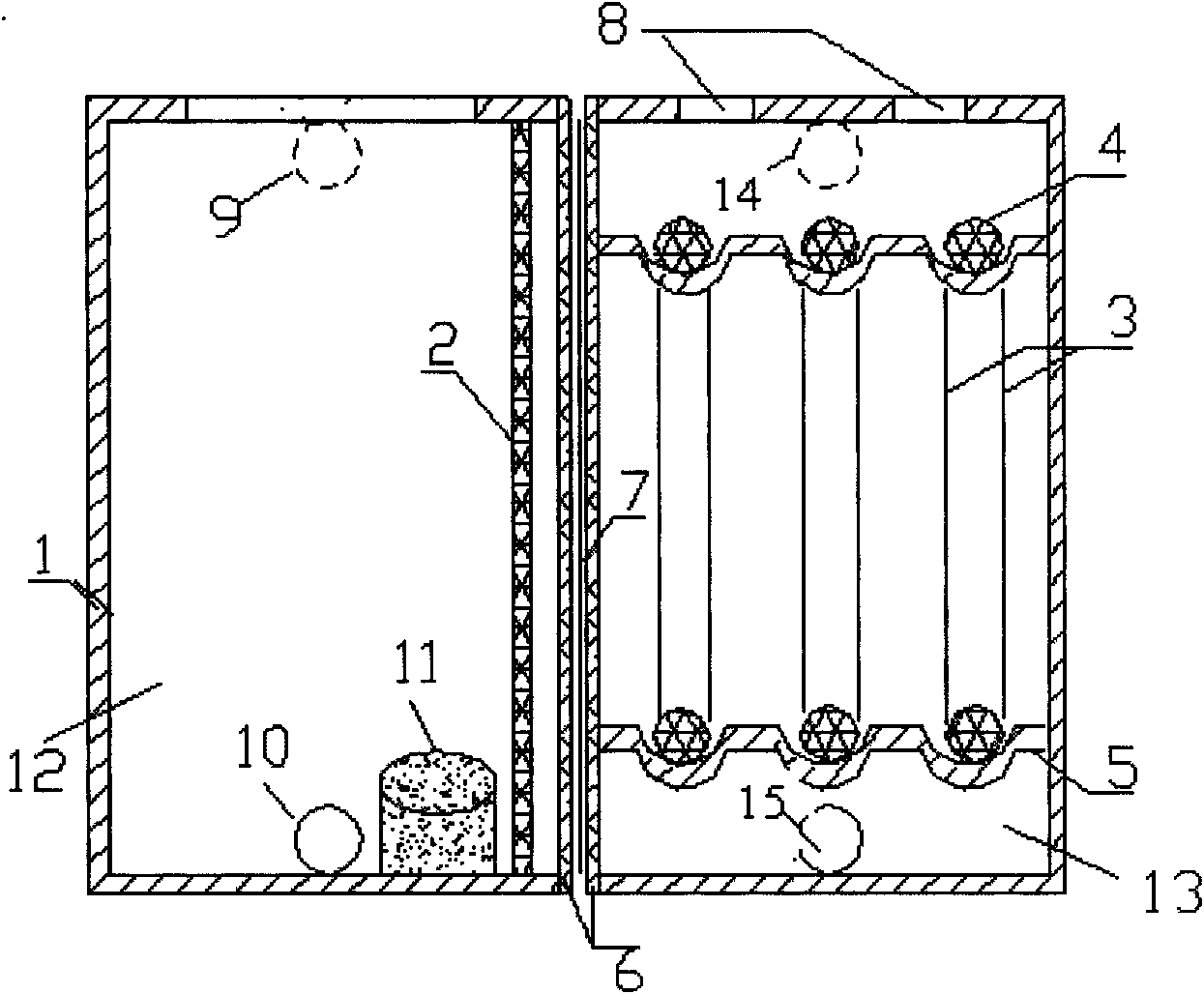

[0030] combine figure 1 , the composition of the reactor 1 of the present invention includes a cathode chamber 12 and an anode chamber 13, the two electrode chambers are separated by a proton exchange membrane 7, the two electrodes are placed in the anode chamber 13 and the cathode chamber 1 respectively, and the anode material adopts carbon fiber 3, carbon fiber 3 is wound on the graphite rod 4 and fixed on the support groove 5. The cathode 2 uses carbon felt. The cathode chamber and the anode chamber of the square reactor are respectively provided with water inlets 10, 15 and water outlets 9, 14 at the lower and upper ends, the anode chamber sealing cover is provided with a test electrode socket 8 in the middle, and the bottom of the cathode chamber is provided with an aeration device 11. The two poles are connected by copper wires, and are connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com