Support leg for semitrailer

A semi-trailer and inner leg technology, applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve the problems of insecure flexibility, high manufacturing cost, long transmission chain, etc., and achieve simplified telescopic range and manufacturing cost The effect of low and few transmission parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

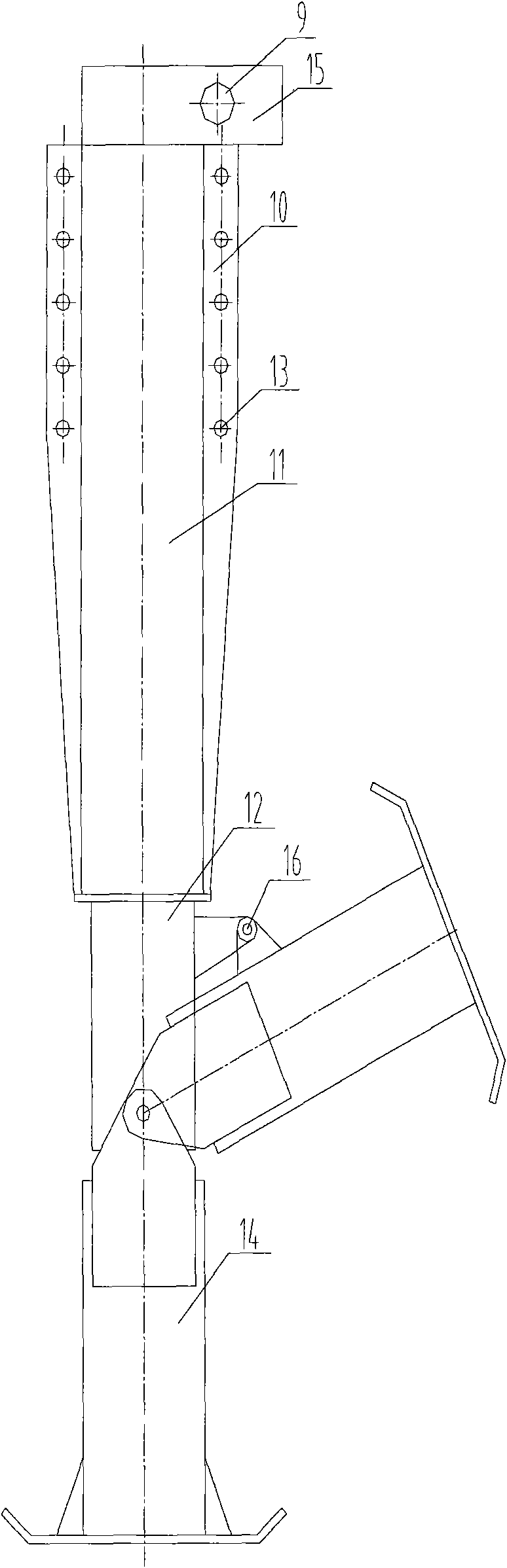

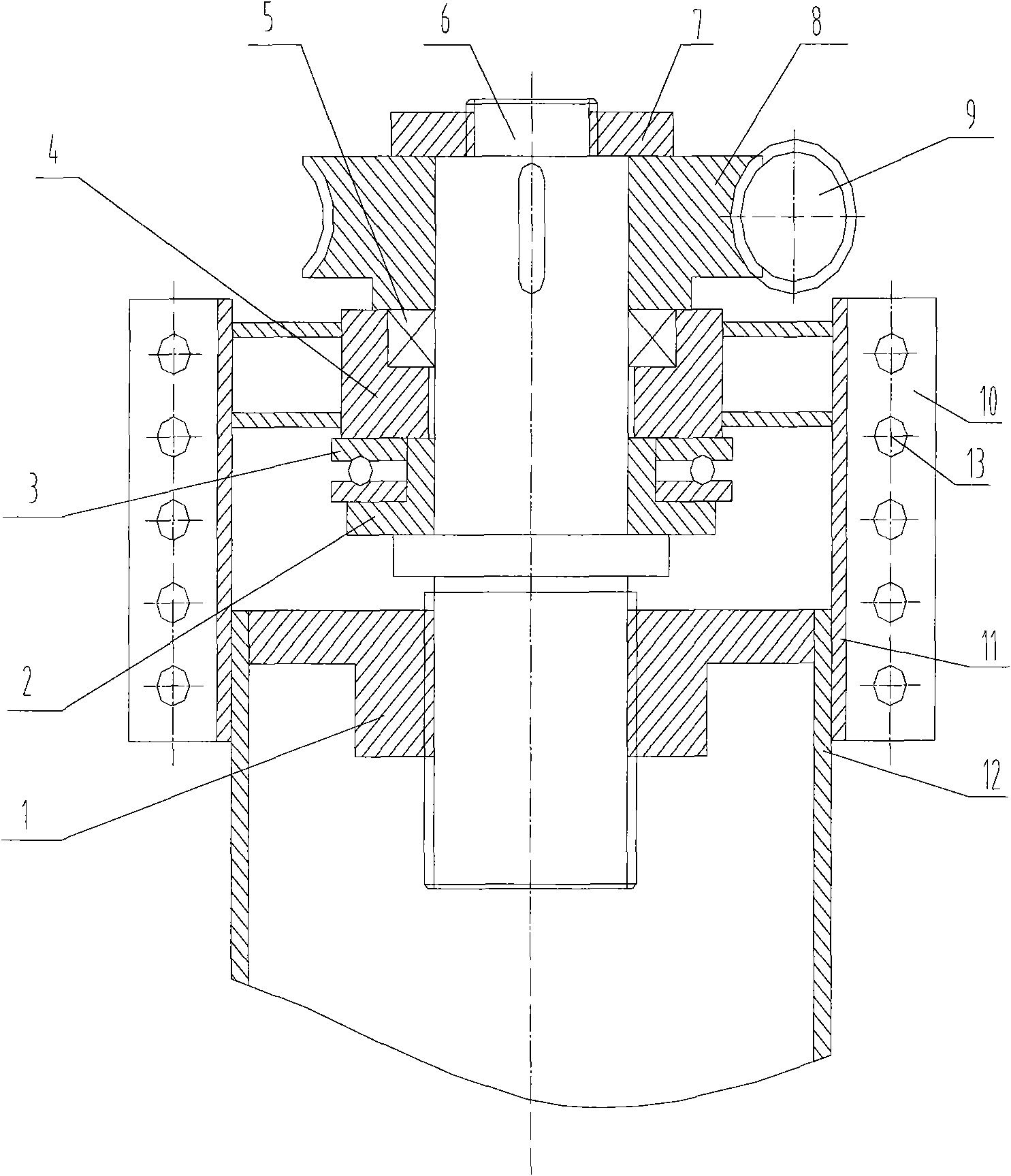

[0025] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes an outer leg 11, a lifting inner leg 12 that can be stretched up and down in the outer leg 11, and a lead screw 6 connecting the outer leg 11 and the lifting inner leg 12, and is characterized in that the lower end of the lifting inner leg 12 is connected with a foldable foot 14. The lead screw 6 is respectively clamped with the screw nut 1 fixed in the lifting inner leg 12 and the ball bearing 5 installed on the inner bearing seat 4 of the outer leg 11. The upper end of the lead screw 6 is installed with a locking nut 7 and a ball bearing 5 There is a worm wheel 8 with a worm 9 on the side fixed up and down; a connecting plate 10 with a screw hole 13 on the surface is fixed on the relative position outside the outer leg 11; the lower end of the bearing seat 4 is provided with a mounting plane around the screw 6 The pressure bearing seat 2 of the bearing 3; the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com