Lifting semitrailer outrigger

A semi-trailer, lift-type technology, applied in the direction of lifting vehicle parts, vehicle maintenance, transportation and packaging, can solve the problems of cumbersome operation, complex structure, high cost, and achieve welding deformation with less, high precision and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

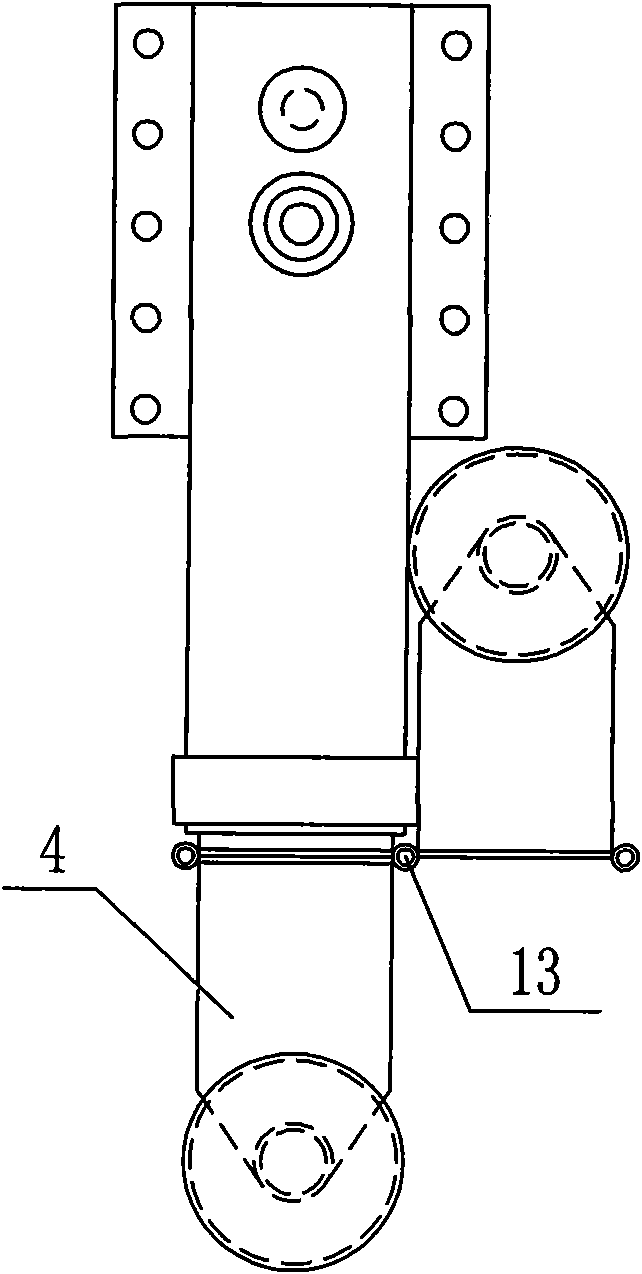

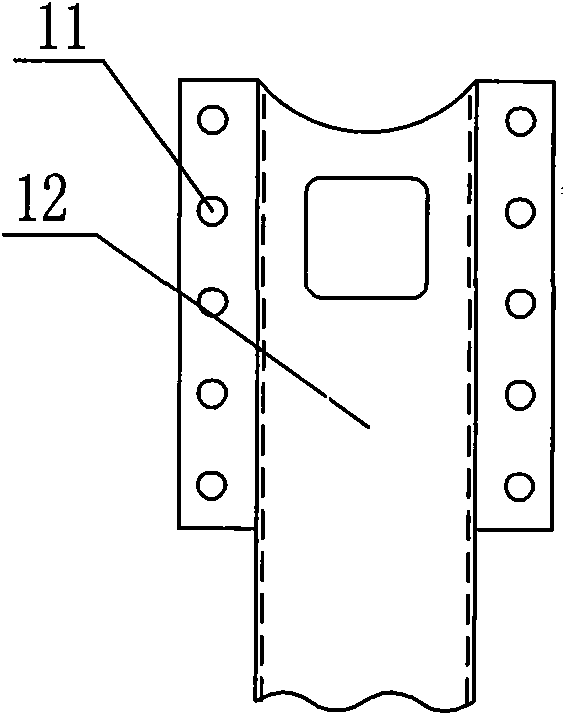

[0017] An elevating semi-trailer outrigger in the present invention comprises an outer leg 1, an elevating inner leg 2 fitted inside the outer leg, and a lead screw 3 connecting the outer leg 1 and the elevating inner leg 2. The lower end of the lifting inner leg 2 is connected with a folding leg 4, and the lower end of the folding leg 4 is a wheel structure; the lead screw 3 is respectively connected with the screw nut 5 fixed on the inner side of the lifting inner leg 2 and the bearing seat 6 fixed on the inner side of the outer leg 1; The top of the screw 3 and the upper end of the bearing seat 6 are connected with a fixed nut 7, the lower end of the bearing seat 6 is connected with a plane pressure bearing 8, and the inner side of the plane pressure bearing 8 is connected with the screw 3; the outer leg 1 is provided with a screw rod 9, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com