Narrow type lithium-ion battery and manufacturing process thereof

A lithium ion battery and a manufacturing process technology, applied in the field of lithium ion battery, the manufacturing process of manufacturing this kind of narrow lithium ion battery, can solve the problems of high cost, difficulty in making the cell width less than 10mm, low production efficiency and the like, achieve easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

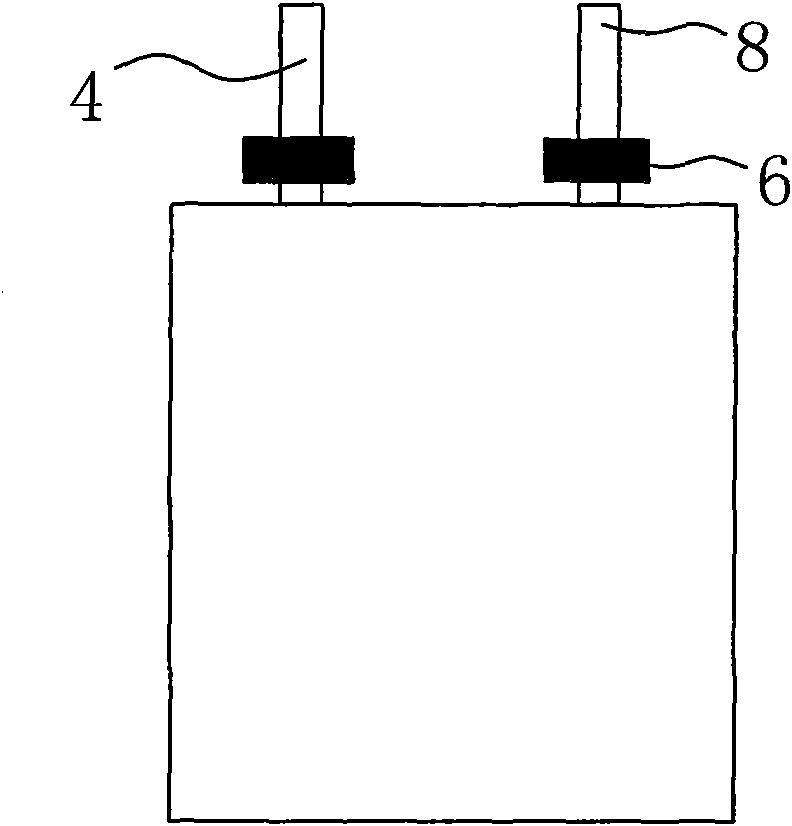

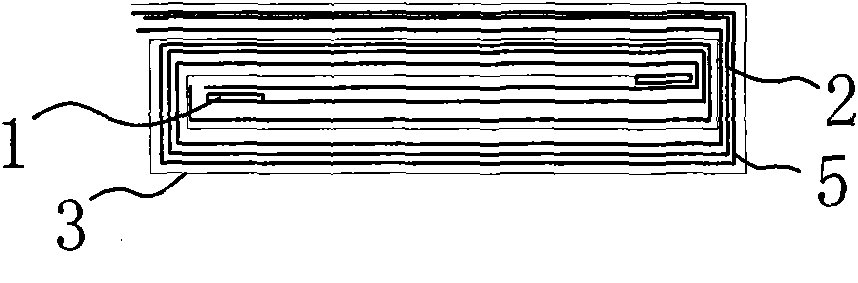

[0035] Such as Figures 4 to 6 Shown, a kind of narrow lithium-ion battery comprises the strip-shaped positive pole piece 2 that is coated with positive active material on the carrier body, is coated with the strip-shaped negative pole piece of negative active material on the carrier body 3. Diaphragm 5, electrolyte, positive tab 4 welded on positive pole piece 2, negative pole tab 8 welded on negative pole piece 3, insulating adhesive film 6 sleeved on the tab, and shell. The positive pole piece 2, the negative pole piece 3, the diaphragm 5, and the electrolyte constitute the battery cell 7 of the lithium-ion battery, and the battery cell 7 is packaged with a casing to make a finished lithium-ion battery. One of the ends of the positive electrode sheet 2 and the negative electrode sheet 3 are L-shaped, the corners 9 of the L-shaped end are rounded, and the protruding portion 1 of the L-shaped end is blank. Fluid, the length h of the protruding part 1 is 2 mm, the width w is ...

Embodiment 2

[0037] The difference from Example 1 is that the protruding portion 1 has a length h of 10 mm and a width w of 2 mm, and the positive electrode tab 4 and the negative electrode tab 8 pass through the same insulating adhesive made of PP material with a length of 4 mm and a width of 4 mm. After the glue sheet 6 is extended into the battery cell 7, the positive pole lug 4 is welded to the protruding part 1 of the L-shaped end of the positive pole piece 2, and the negative pole lug 8 is welded to the L-shaped end of the negative pole piece 3. 1 protruding part. The parameters of the lithium-ion battery of the present embodiment are as follows: the width of the pole piece is 4mm, the width (including the diaphragm) of the cell after vertical winding is 5mm, the width of the tab is 1mm, and the width of the insulating adhesive film 6 is 4mm. The minimum width can be made about 6mm. At the same time, since the distance between the two tabs is determined by the connected tabs, it has...

Embodiment 3

[0039] The difference from Example 1 is that the protruding part 1 has a length h of 20 mm and a width w of 3 mm, and the positive electrode tab 4 and the negative electrode tab 8 pass through the same insulating adhesive made of PP material with a length of 10 mm and a width of 7 mm. After the glue sheet 6 is extended into the battery cell 7, the positive pole lug 4 is welded to the protruding part 1 of the L-shaped end of the positive pole piece 2, and the negative pole lug 8 is welded to the L-shaped end of the negative pole piece 3. 1 protruding part. The lithium-ion battery parameter of present embodiment is as follows: the width of pole piece is 6mm, the width (comprising membrane) of electric core after vertical winding is 7mm, the width of tab is 2mm, the width of insulating bonding film 6 is 7mm, The minimum width of the battery can be made about 8mm. At the same time, since the distance between the two tabs is determined by the connected tabs, it has nothing to do w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com