Self-balancing test device and method for directly testing axial tensile strength of early-age concrete

An axial tensile and concrete technology, which is applied to measuring devices, using stable tension/pressure to test material strength and strength characteristics, etc., can solve the problems of low test success rate, test failure, low concrete strength, etc. High precision, simple assembly and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in detail:

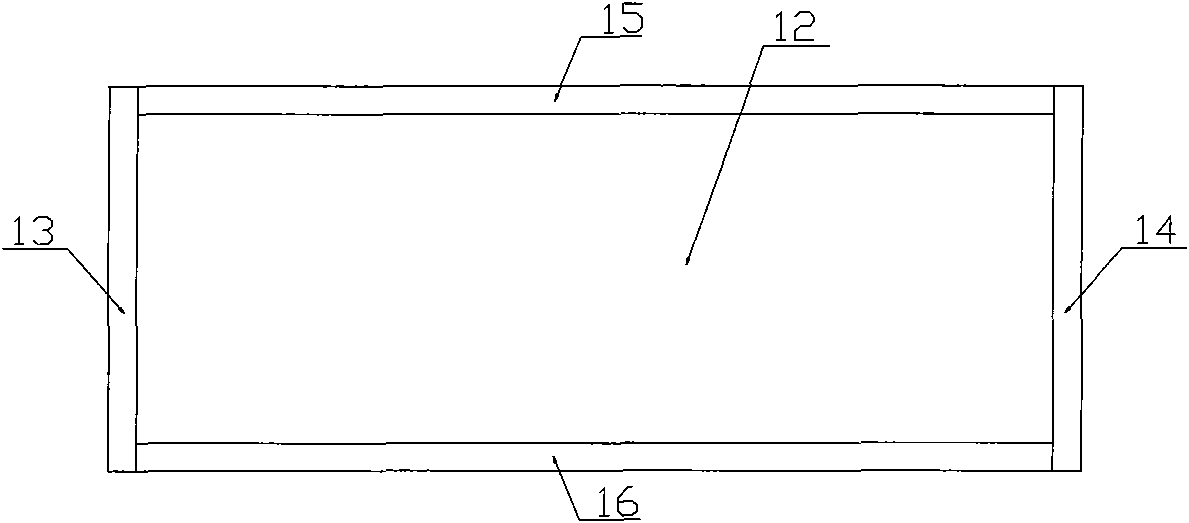

[0026] A self-balancing test device for directly measuring the axial tensile strength of early-age concrete, including an outer frame 1, an inner formwork 2, a dowel bar 3, a hydraulic hollow jack 4, a hollow load sensor 5, a ball hinge 6, a locking Nut 7, hydraulic oil pump 8 and resistance strain gauge 9 form the force adding device. The hydraulic hollow jack 4 is connected with the hydraulic oil pump 8 through the oil pipe 10 to realize loading on the early-age concrete specimen. The hollow load sensor 5 is connected with the resistance strain gauge 9 through the four-core wire 11 to test the load during the test.

[0027] The method that adopts the self-balancing test device of the early age concrete axial tensile strength of the present invention to measure the axial tensile strength of early age concrete is to comprise the following steps during the test:

[0028] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com