Method for producing ferronickel by utilizing low-magnesium intermediate type laterite nickel ore

A technology of lateritic nickel ore and ferronickel, applied in the direction of improving process efficiency, can solve problems such as difficult to handle, unsuitable for wet process technology, high iron and low magnesium, and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

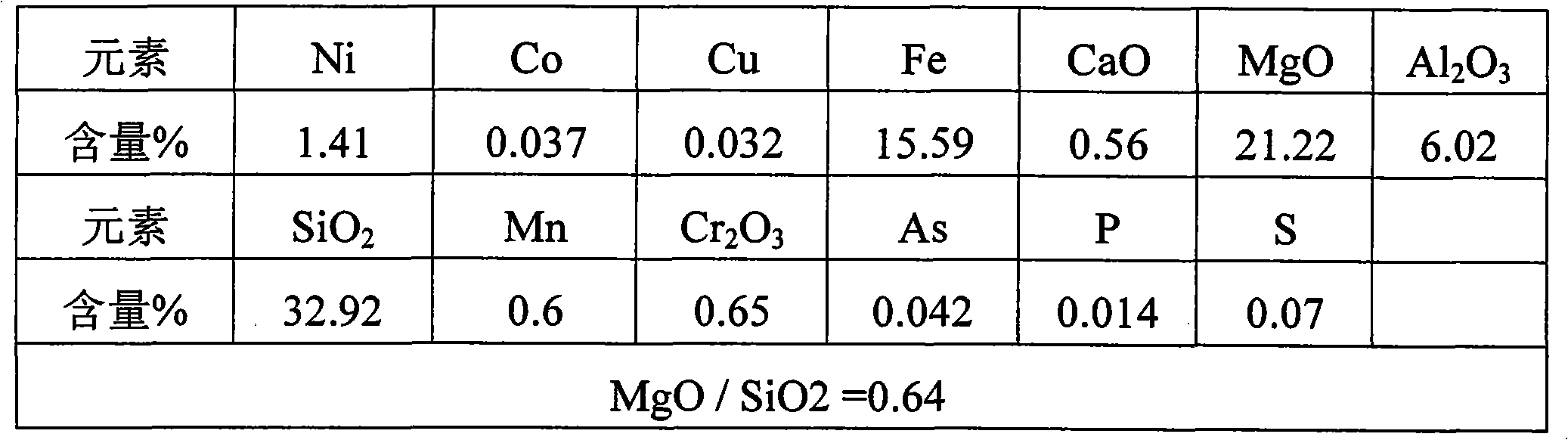

Embodiment 1

[0025] Roasting pre-reduction, after crushing, sieving, granulating, and drying, dry-based laterite nickel ore with a moisture content of less than 20% is mixed with about 10% anthracite and 6% CaO by weight for pre-reduction roasting treatment. Granular force is 5-10mm, time is 30-50 minutes, temperature is 800-900°C, iron reduction degree is controlled at 70% for smelting, that is, roasted calcine and recycled dust are mixed with a reducing agent with a weight ratio of 3%. Join the open-arc smelting in the transferred arc DC electric furnace. The slag was separated to obtain a ferronickel smelting product with Ni 8.52% and Fe 73.5%.

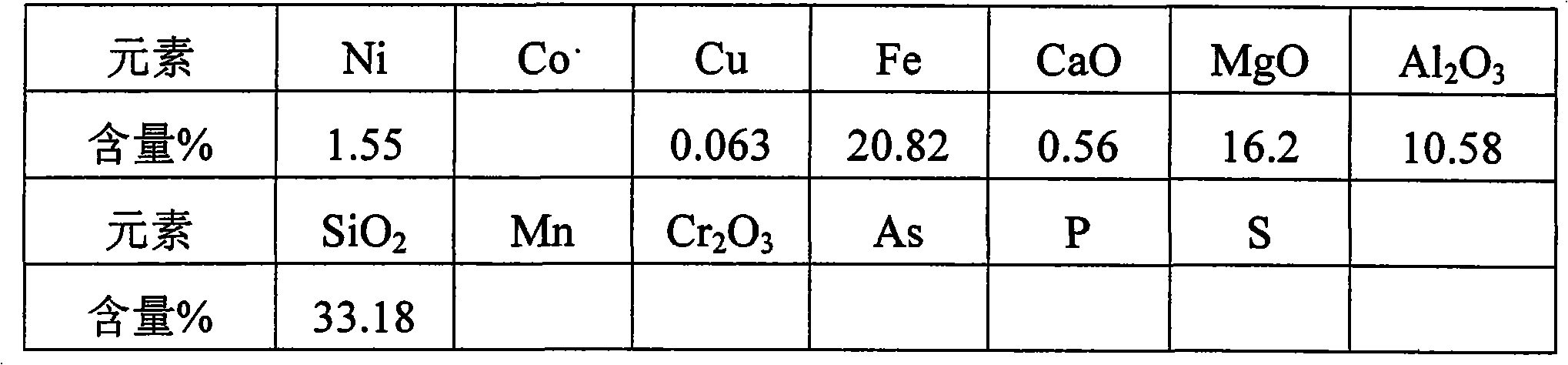

Embodiment 2

[0027] Roasting pre-reduction, after crushing, sieving, granulating, and drying, dry-based laterite nickel ore with a moisture content of less than 20% is mixed with about 10% anthracite and 7% CaO by weight for pre-reduction roasting treatment. Granular force is 5-10mm, time is 30-50 minutes, temperature is 800-900°C, iron reduction degree is controlled at 80% for smelting, that is, roasted calcine and recycled dust are mixed with a reducing agent with a weight ratio of 2%. Join the open-arc smelting in the transferred arc DC electric furnace. The slag was separated to obtain a ferronickel smelting product with Ni 10.34% and Fe 81.2%.

Embodiment 3

[0029] Roasting pre-reduction, after crushing, sieving, granulating, and drying, the dry basis laterite nickel ore with a moisture content of less than 20% is mixed with about 10% anthracite and 2% CaO by weight, and the pre-reduction roasting treatment is carried out. Granular force is 5-10mm, time is 30-50 minutes, temperature is 800-900°C, iron reduction degree is controlled at 70% for smelting, that is, roasted calcine and recycled dust are mixed with a reducing agent with a weight ratio of 1%. Join the open-arc smelting in the transferred arc DC electric furnace. The slag was separated to obtain a ferronickel smelting product with Ni 11.06% and Fe 80.42%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com