Invert plasma cutter

A plasma cutting machine, cutting machine technology, applied in the direction of plasma welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as grid pollution, achieve the effect of improving service life, reducing weight and volume, and reducing effective current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

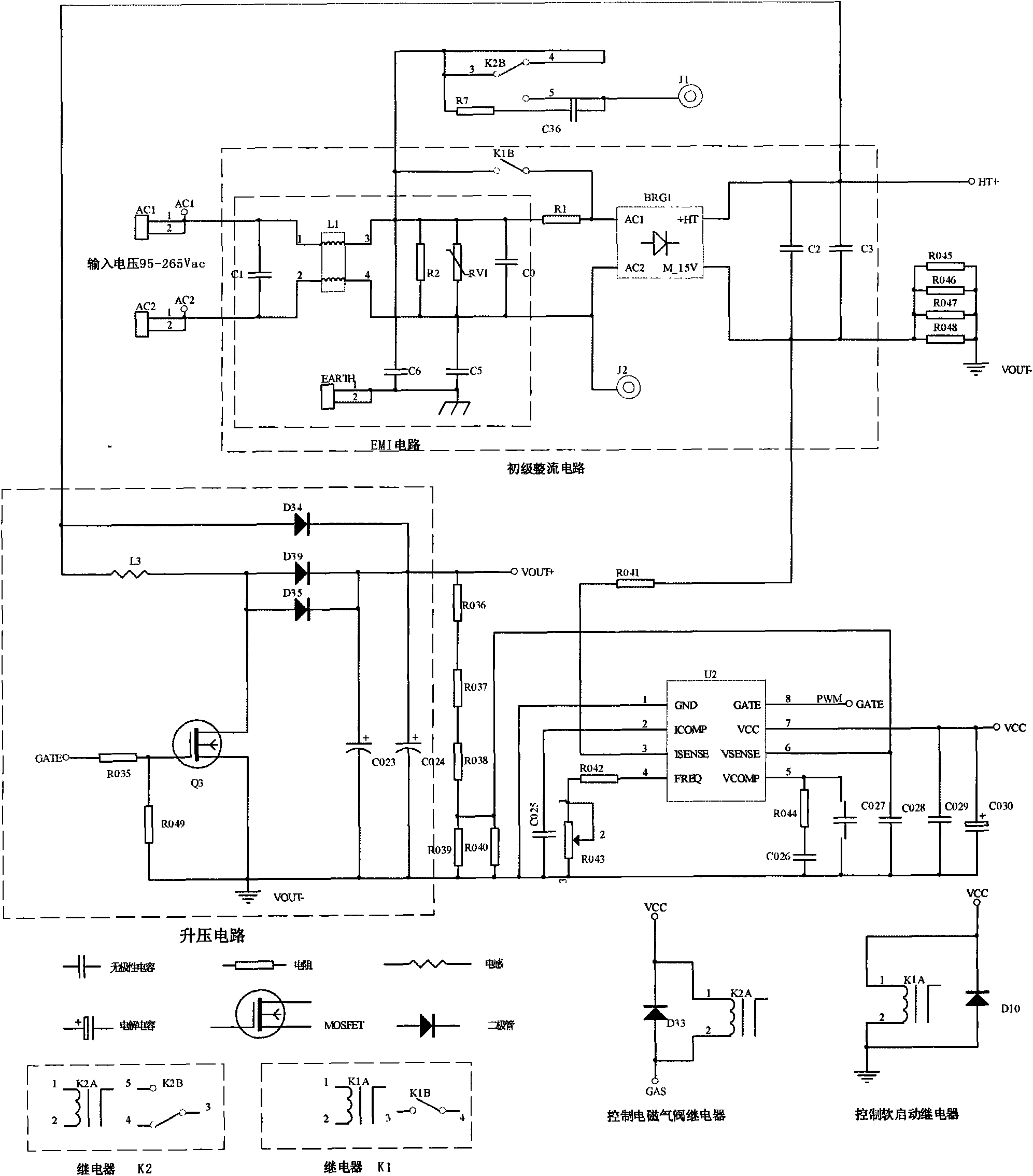

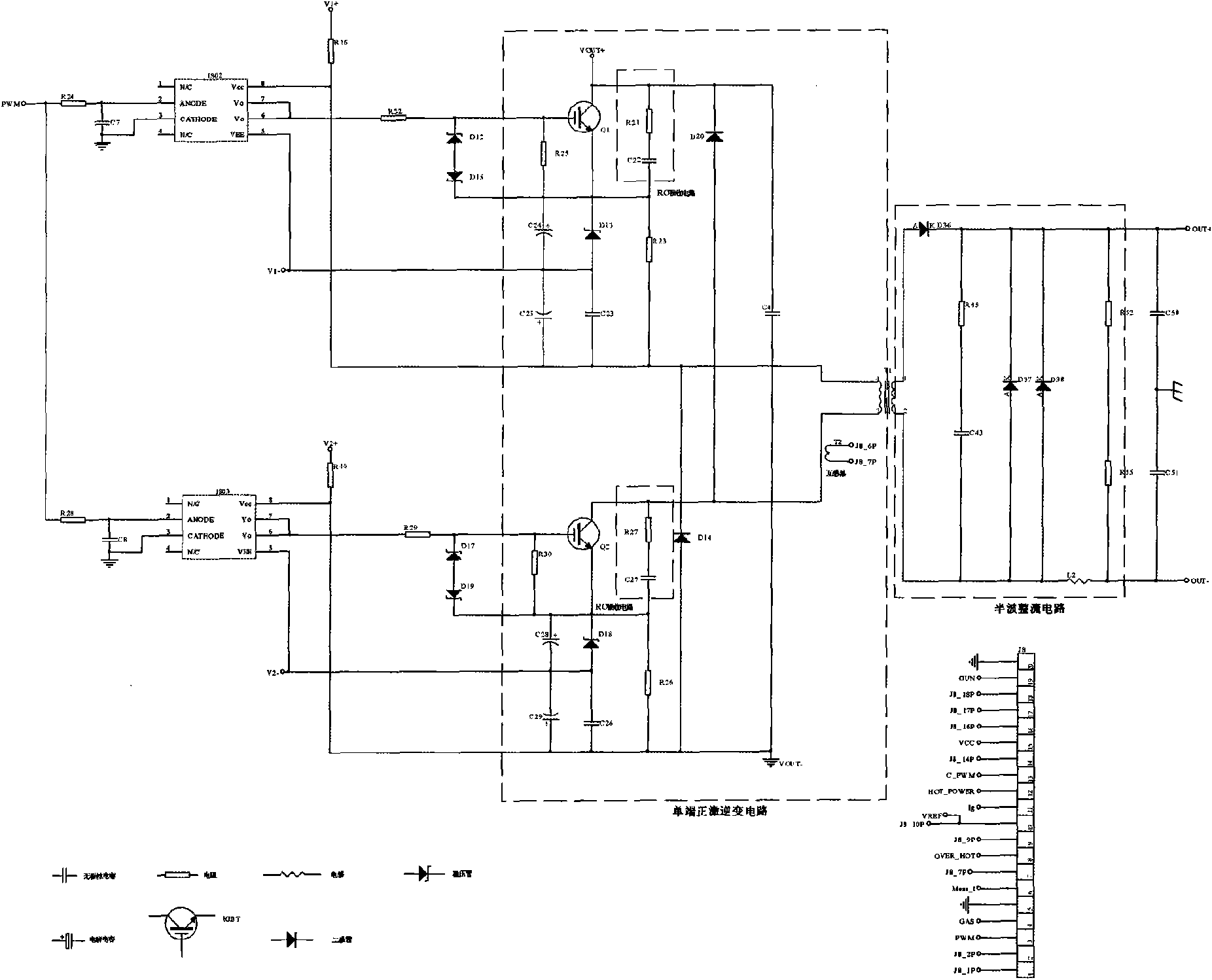

[0032] Such as figure 1 As shown, the internal components of an inverter plasma cutting machine provided by the present invention have a special arrangement structure, and the fan, main power components and radiators are arranged crosswise in the internal structure of the whole machine. The main power components are fixed on the radiator, the rear fan 3 is fixed on the back cover, and the outside air is pumped through the louvers on the back cover to the fourth radiator 4, the fifth radiator 5, the sixth radiator 6 and the inductor 2 for heat dissipation, the middle fan 7 is fixed on the printed circuit board 1 to dissipate heat for the eighth radiator 8, main transformer 9 and output inductor 10, and pass the heat generated by the radiator, transformer and inductor through the mesh on the front cover The cooling holes and the louvers on the side of the upper cover blow to the outside of the machine. The rear fan 3, the middle fan 7, the fourth radiator 4, the fifth radiator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com