Extraction method of fresh chive oil

A kind of extraction method and chive oil technology, applied in the field of food chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

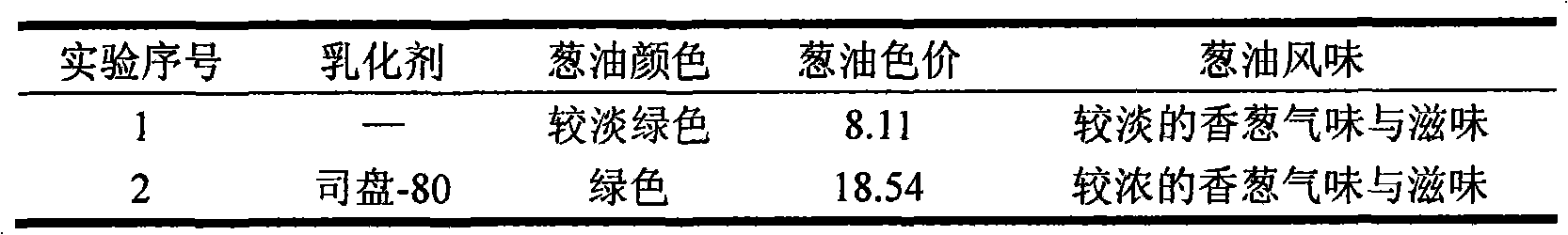

[0030] (1) Get fresh chives and cut flowers, add its weight 0.2% (w: w) Span-80 and 100% (w: v) salad oil, mix and mince, then transfer to a low-temperature microwave extraction device, set the microwave The power is 2400W, the temperature is 25-45°C (in actual operation, the upper limit of the instrument temperature can be set to 45°C, the same below), the material flow rate is 52L / h; press filter, collect the filtrate and filter residue for later use;

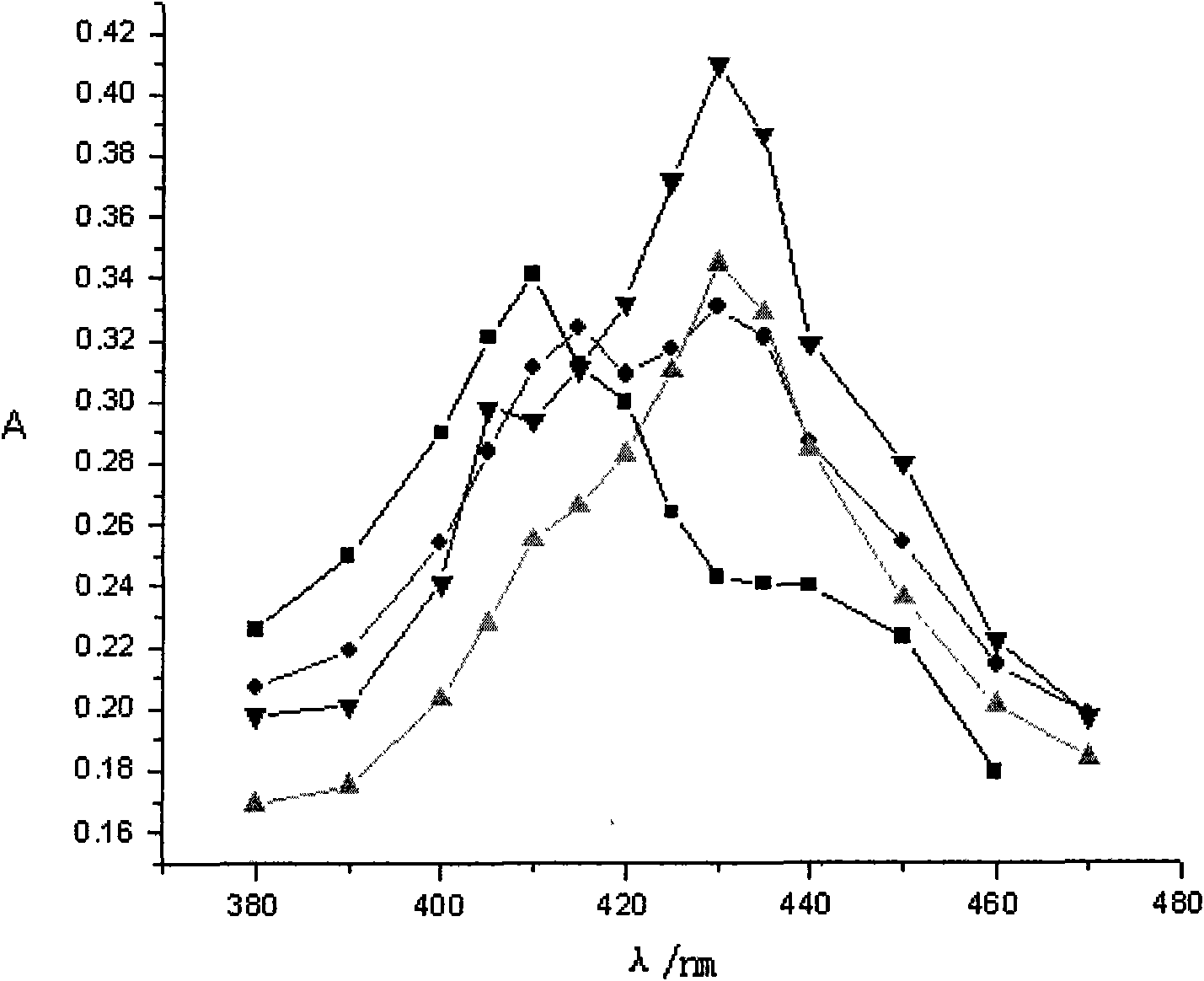

[0031] (2) Get the filtrate obtained in step (1), let stand for layering and liquid separation, remove the light yellow water phase of the lower floor, take the green oil phase of the upper layer, centrifuge at 4000r / min, further remove water, add 5% of the oil phase (v:w ) of calcium chloride was dried for 1h, filtered to obtain clear green shallot oil A; its color value was 18.31 measured with a spectrophotometer, and the oil recovery rate was 67.78%;

[0032] (3) Transfer the obtained filter residue of step (1) to a low-te...

example 2

[0035] (1) Get fresh chives and cut flowers, add 0.02% of its weight Span-60 and 50% of salad oil, mix and grind, then transfer to a low-temperature microwave extraction device, set the microwave power to 1600W, and the temperature is 25 to 35°C , the material flow rate is 30L / h for continuous extraction; press filtration, collect the filtrate and filter residue for later use;

[0036] (2) Get the filtrate obtained in step (1), let stand for layering and liquid separation, remove the light yellow water phase of the lower floor, get the green oil phase of the upper layer, and centrifuge at 4000r / min to further remove water, add 2% of the oil phase (v:w ) of calcium chloride was dried for 2h, filtered to obtain clear green chive oil A; its color value was 14.81 measured with a spectrophotometer, and the oil recovery rate was 51.23%;

[0037] (3) The filter residue obtained in step (1) is transferred to a low-temperature microwave extraction device, and 4 volume times (w: v) of a...

example 3

[0040] (1) Get fresh chives and cut flowers, add 0.01% of its weight Span-20 and 200% of salad oil and grind together, transfer to a low-temperature microwave extraction device, set the microwave power to 3200W, and the temperature is 25 to 55°C. Continuous extraction at a flow rate of 200L / h; pressure filtration, collecting filtrate and filter residue for later use;

[0041](2) Get the filtrate obtained in step (1), let stand for layering and liquid separation, remove the light yellow water phase of the lower layer, take the green oil phase of the upper layer, and centrifuge at 4000r / min to further remove water, add 10% of the oil phase (v:w ) of calcium chloride was dried for 20min, filtered to obtain clear green shallot oil A; its color value was 19.64 measured with a spectrophotometer, and the oil recovery rate was 69.23%;

[0042] (3) Transfer the obtained filter residue of step (1) to a low-temperature microwave extraction device, add acetone and petroleum ether mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com