Method for pouring underwater cast-in-situ bored pile

A technology for bored piles and concrete, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve problems such as non-compliance with energy conservation and emission reduction, waste of resources, etc., and achieve the effect of saving resources and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

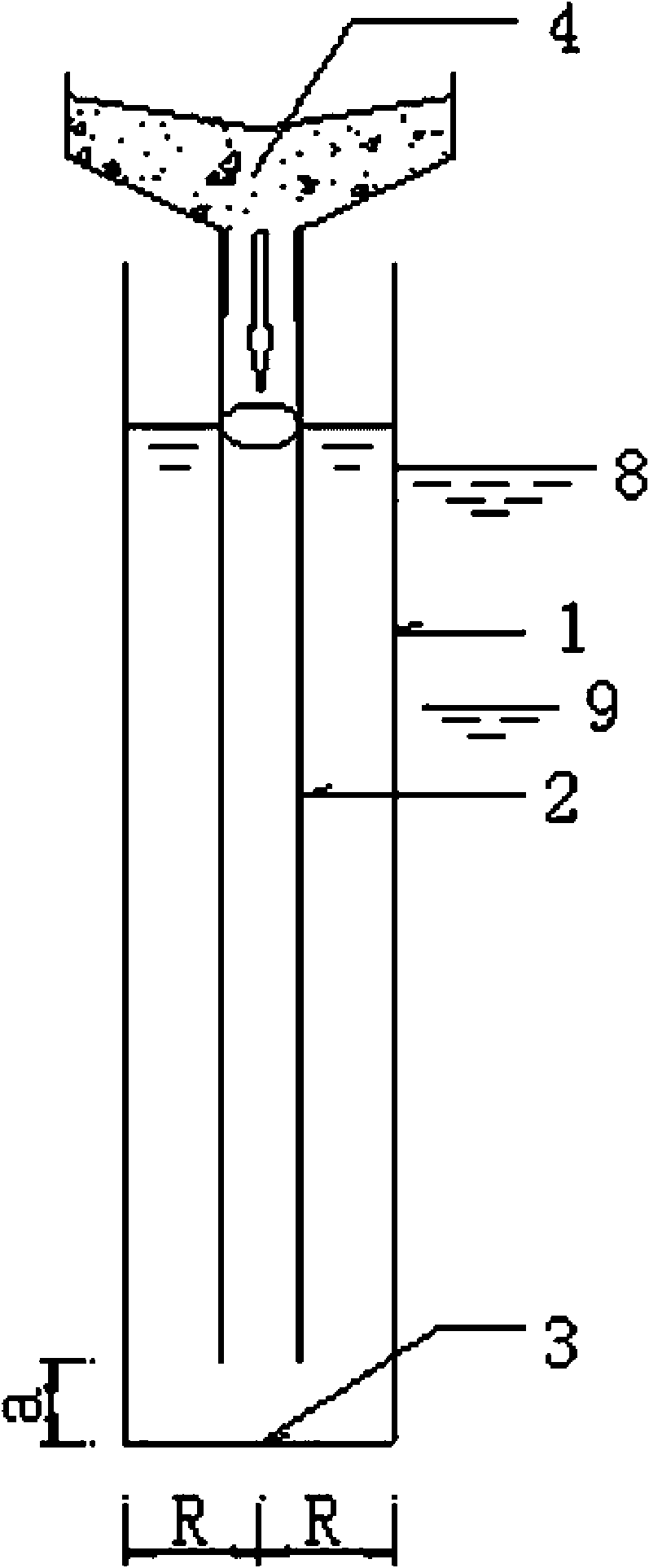

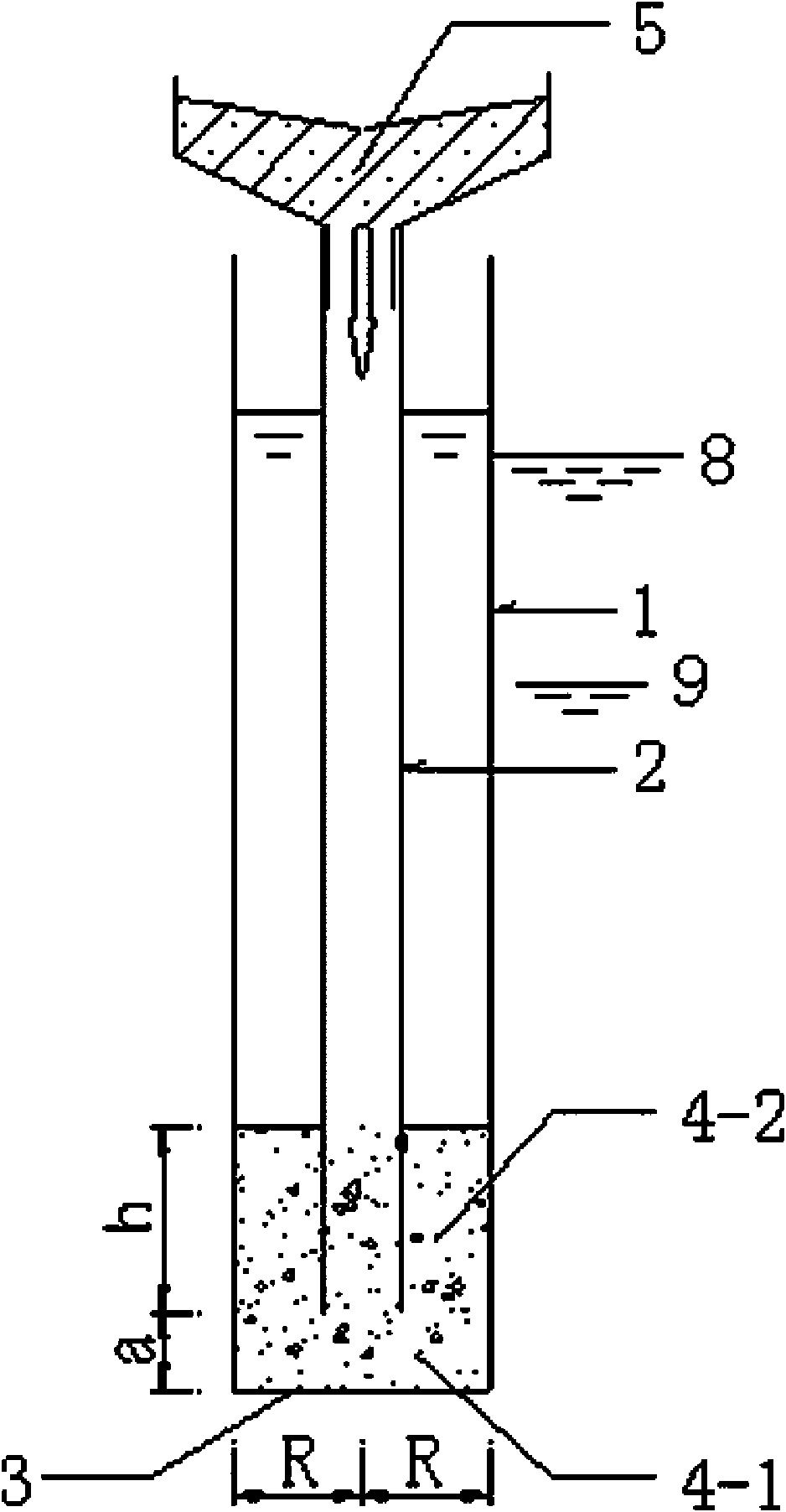

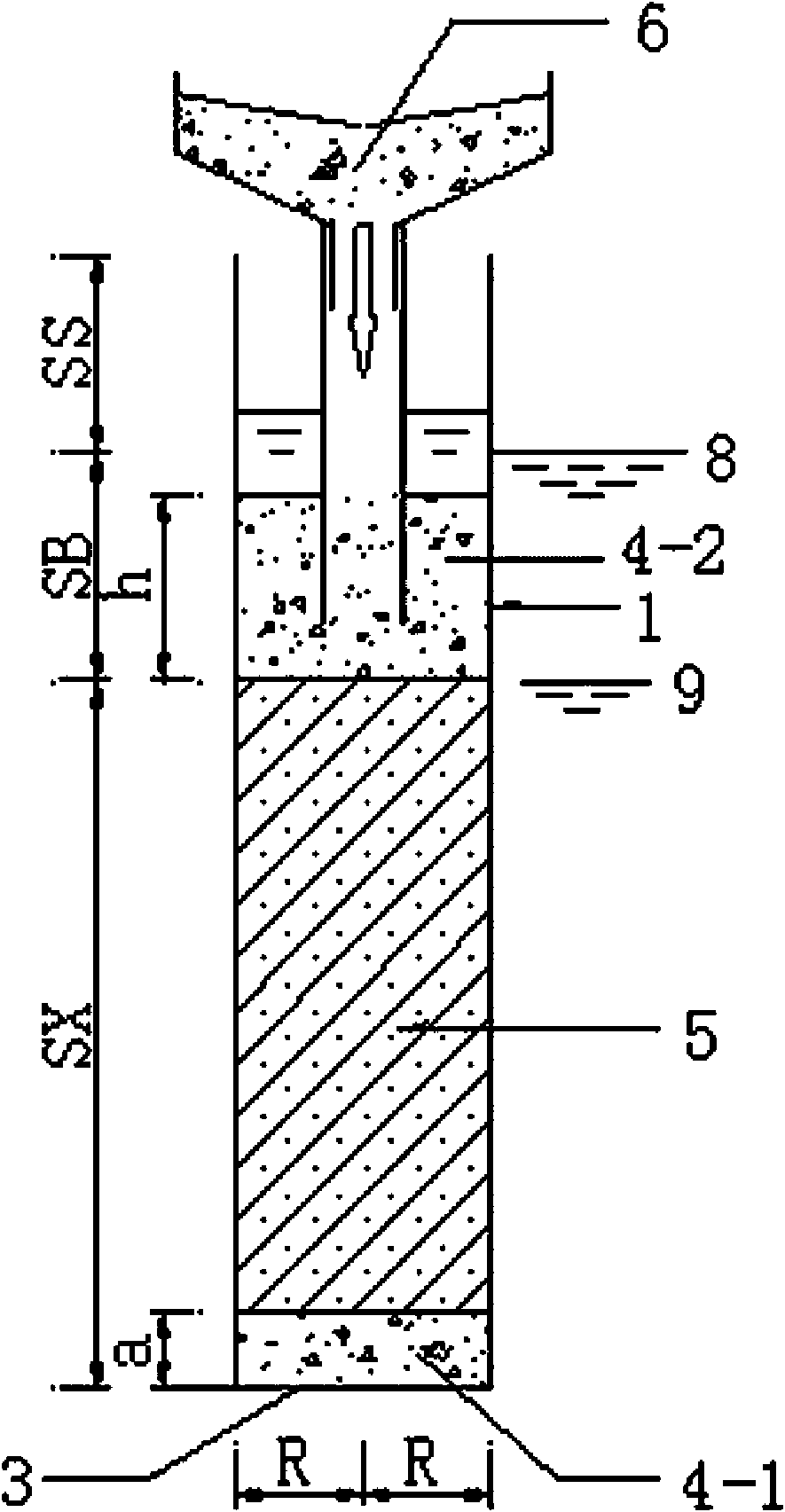

[0015] The general construction sequence of bored piles is: drilling→clearing the hole once, the elevation of the hole bottom meets the design requirements→lowering the reinforcement cage→lowering the concrete conduit→cleaning the hole twice, the specific gravity of the mud and the thickness of the sediment at the bottom of the hole meet the specifications and design requirements →Pouring concrete.

[0016] Pile-forming principle of bored cast-in-place pile concrete: Concrete is poured by the conduit method, the concrete is poured in from the top of the pouring pipe, and flows out from the bottom. The concrete within the volume of the bottom end, and the other part is the concrete within the depth range of the buried pipe, that is, the concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com