Preparation method of polyacrylonitrile carbon fiber

A technology of polyacrylonitrile-based carbon fiber and polyacrylonitrile, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc. It can solve the problems of unsuitable temperature control, complex equipment, high cost, etc., so as to reduce energy consumption, reduce tensile strength, improve Effect of pre-oxidation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

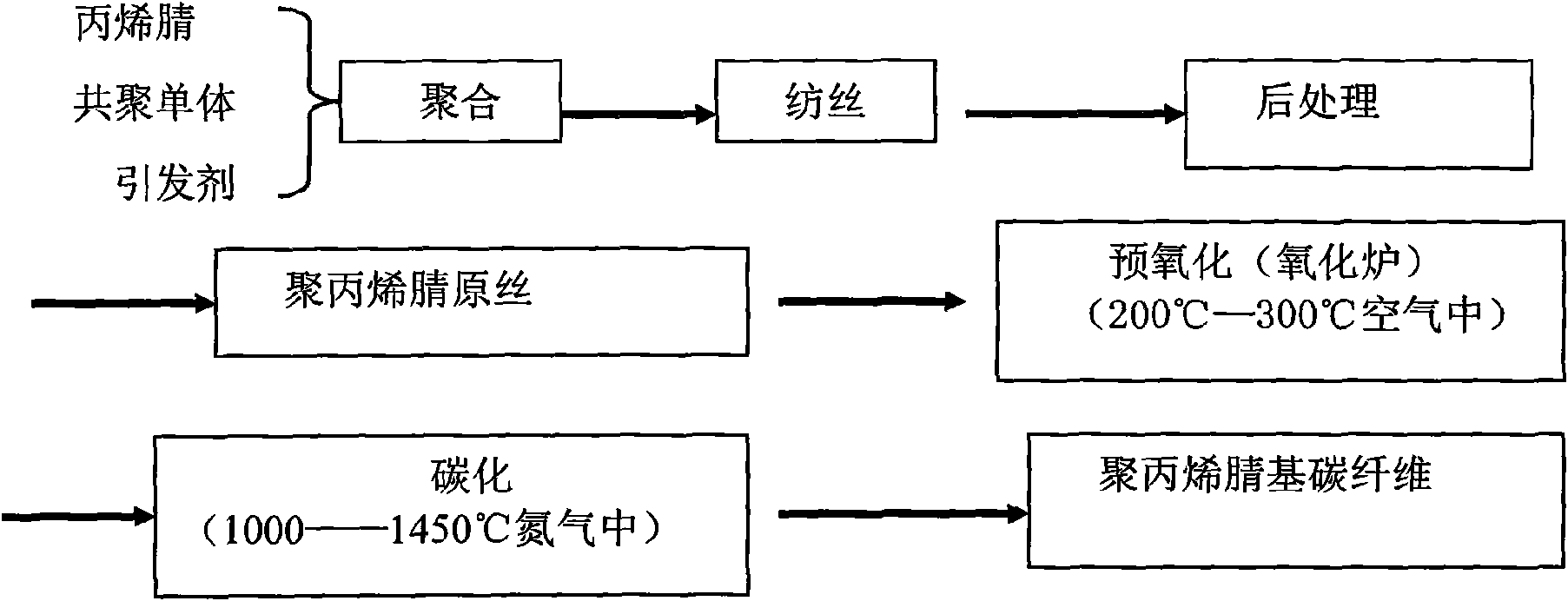

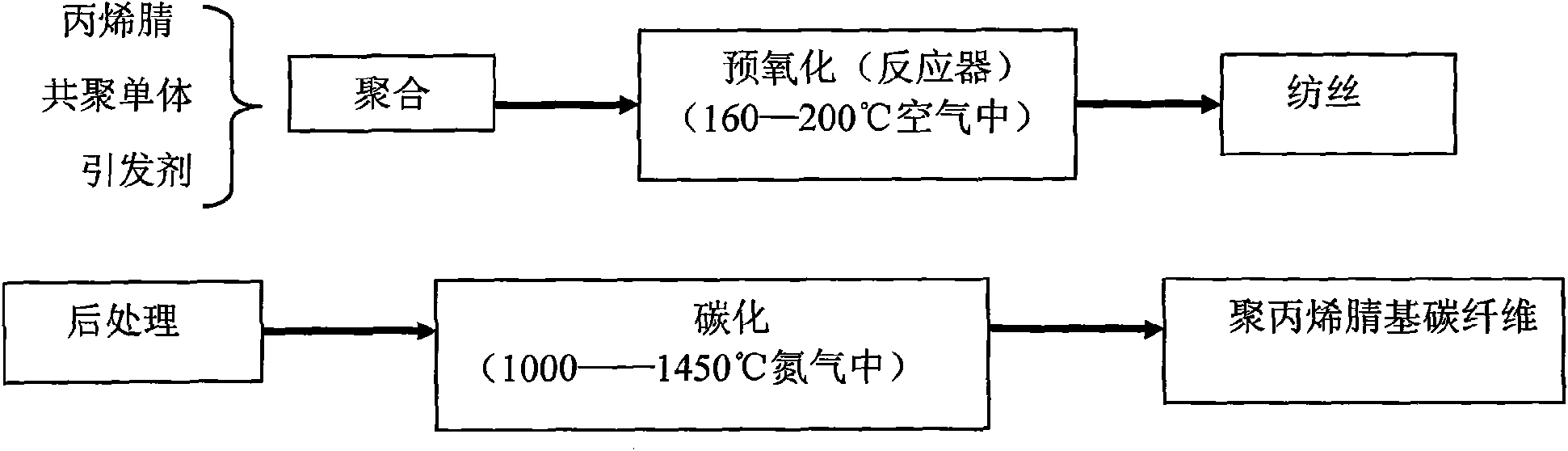

Method used

Image

Examples

Embodiment 1

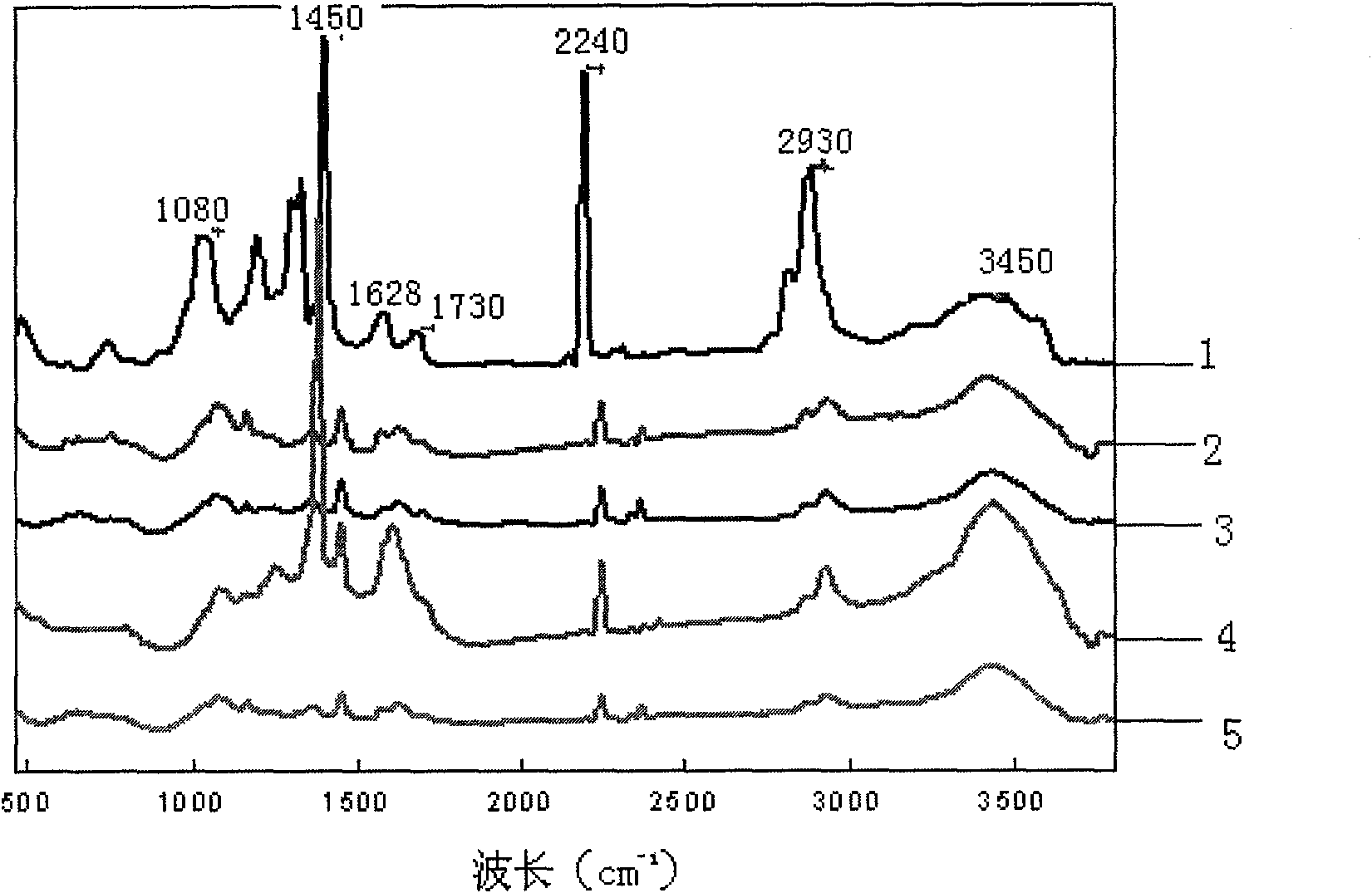

[0044] Add 1-butyl-3-methylimidazolium chloride salt type ionic liquid and polyacrylonitrile powder into the reactor with mechanical stirring device, and add catalyst KMnO after the polymer is completely dissolved 4, to promote the cyclization of polyacrylonitrile. The mass fractions of the added raw materials are: polyacrylonitrile is 5%, and solvent is 95%. QUR 4 The mass accounts for 0.05% of polyacrylonitrile. The mixture was stirred and reacted at 170°C, and a certain flow of oxygen was introduced to control the temperature and time of the pre-oxidation reaction, and samples were taken at 20 min, 40 min, 60 min, and 90 min to obtain polyacrylonitrile spinning solutions with different pre-oxidation degrees. diagram 2-1 IR spectra of PAN / IL pre-oxidized at 170°C for different times.

Embodiment 2

[0046] Add 1-butyl-3-methylimidazolium chloride salt type ionic liquid and polyacrylonitrile into the reactor with mechanical stirring device, and add the catalyst KMnO after the polymer is completely dissolved 4 , to promote the cyclization of polyacrylonitrile. The mass fractions of the added raw materials are: polyacrylonitrile is 5%, and solvent is 95%. QUR 4 The mass accounts for 0.05% of polyacrylonitrile. The mixture was stirred and reacted at 160°C, and an oxygen-containing gas was introduced at a rate of 5ml / min to control the temperature and time of the pre-oxidation reaction, and samples were taken at 20min, 40min, 60min, 90min, 120min, and 150min to obtain different oxidation rates. Degree of polyacrylonitrile spinning solution. Figure 2-2 IR spectra of PAN / IL preoxidized at 160℃ for different times

Embodiment 3

[0048] Add DMSO and polyacrylonitrile into the reactor with a mechanical stirring device, and add the catalyst KMnO after the polymer is completely dissolved 4 , to promote the cyclization of polyacrylonitrile. The mass fractions of the added raw materials are: polyacrylonitrile is 10%, and DMSO is 90%. QUR 4 The mass accounts for 0.05% of polyacrylonitrile. The mixture was stirred and reacted at 175° C., and an oxygen-containing gas was introduced at a rate of 5 ml / min to control the temperature and time of the pre-oxidation reaction. The time was about 4-5 hours to obtain a polyacrylonitrile spinning solution. image 3 IR spectra of PAN / DMSO preoxidized at 175°C for different times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com