Surface active accelerant agent and method for catalytic nitriding by using same

A technology of surface activation and infiltration agent, applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problem of gas and drip tube Louis crystal blockage, difficulty in nitriding process control, and uniformity of infiltration and poor reproducibility, etc., to achieve a significant effect of nitriding and catalytic infiltration, improve operability, and achieve good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

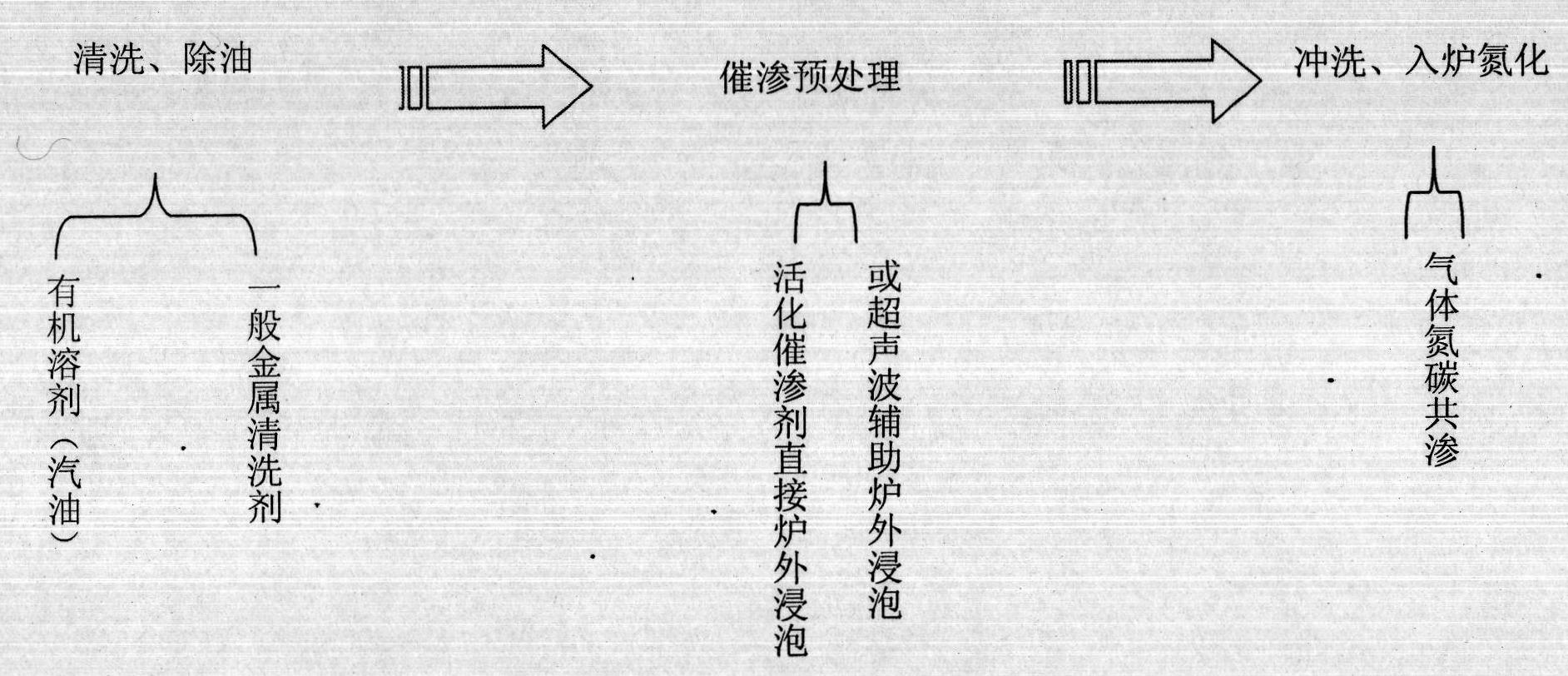

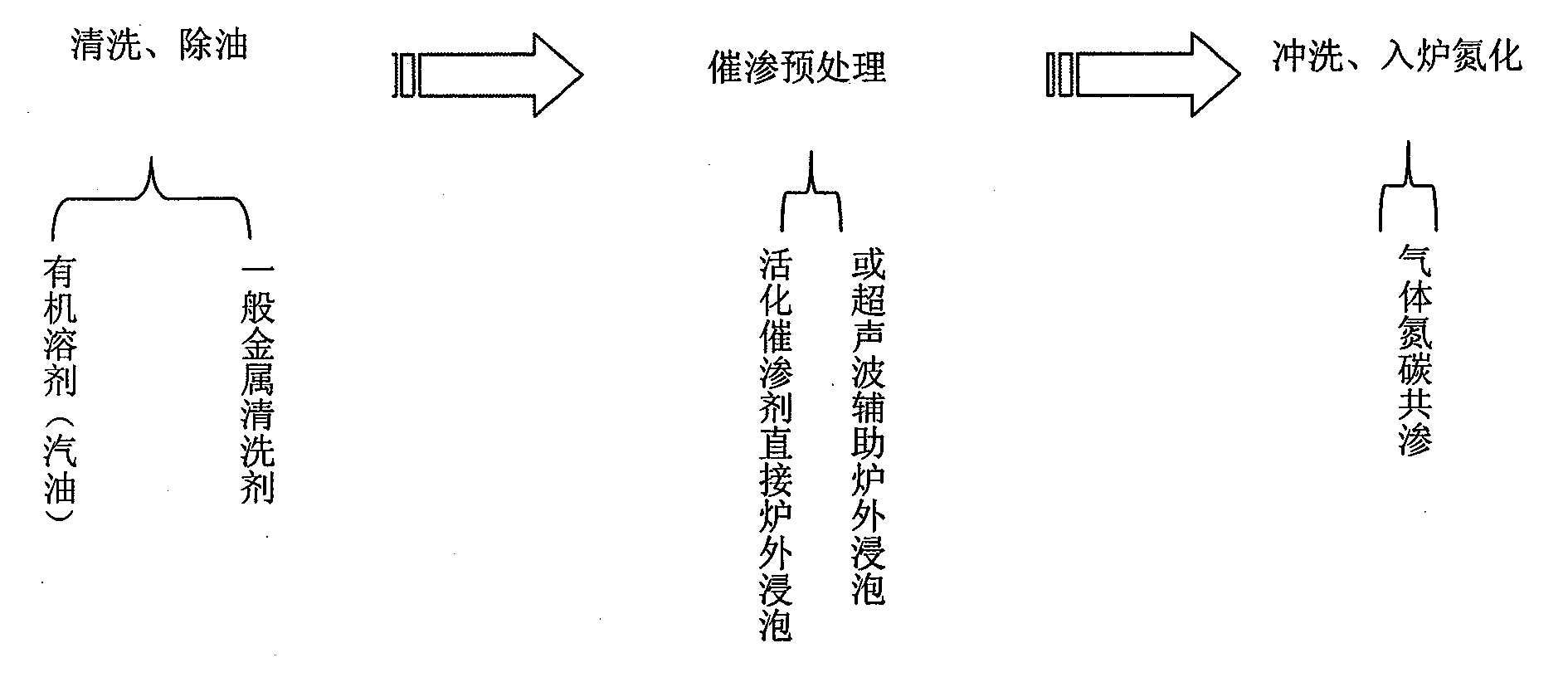

Method used

Image

Examples

Embodiment 1

[0040] Immerse the parts in an aqueous solution of 3% metal cleaning agent by mass, and perform manual cleaning or ultrasonic cleaning for 5 minutes, and the frequency of ultrasonic cleaning is 20kHz. Prepare the surface activation penetrating agent, take 50 grams of H 3 PO 4 , 8 g NaNO 2 , 8 g urea, 8 g NaH 2 PO 4 , 2 grams of glycerol, 2 grams of sodium benzoate and the remainder being water. Get the pure aqueous solution that will prepare 1 / 2 of the total amount of surface-activated penetrating agent, mix H 3 PO 4 Slowly add to the aqueous solution, and keep stirring slowly; then add NaNO 2 , urea, NaH 2 PO 4, glycerin, sodium benzoate, stirring continuously during the adding process; finally add purified water to the total amount of surface-activated penetrating agent to be prepared, and stir evenly. Immerse the part in the osmotic agent activated at 60°C, start the ultrasonic switch, and keep the ultrasonic frequency at 40kHz for 5min. Take out the parts and rin...

Embodiment 2

[0042] Immerse the parts in an aqueous solution of 4% metal cleaning agent by mass, and perform manual cleaning or ultrasonic cleaning for 10 minutes at room temperature, and the frequency of ultrasonic cleaning is 80kHz. Preparation of surface activated penetrating agent, get 150 grams of H 3 PO 4 , 4 g NaNO 2 , 4 g urea, 4 g NaH 2 PO 4 , 2 grams of glycerin, 2 grams of sodium benzoate, and the balance is water. Get the pure aqueous solution that will prepare 1 / 2 of the total amount of surface-activated penetrating agent, mix H 3 PO 4 Slowly add to the aqueous solution, and keep stirring slowly; then add NaNO 2 , urea, NaH 2 PO 4 , glycerin, sodium benzoate, stirring continuously during the adding process; finally add purified water to the total amount of surface-activated penetrating agent to be prepared, and stir evenly. Immerse the part in the osmotic agent activated at 45°C, start the ultrasonic switch, and keep the ultrasonic frequency at 80kHz for 15 minutes. ...

Embodiment 3

[0044] Immerse the parts in an aqueous solution of 5% metal cleaning agent by mass, and perform manual cleaning or ultrasonic cleaning at 60°C for 30 minutes, and the ultrasonic cleaning frequency is 130kHz. Preparation of surface activated penetrating agent, get 300 grams of H 3 PO 4 , 2 g NaNO 2 , 2 g urea, 2 g NaH 2 PO 4 , 1 gram of glycerin, 1 gram of sodium benzoate, and the balance is water. Get the pure aqueous solution that will prepare 1 / 2 of the total amount of surface-activated penetrating agent, mix H 3 PO 4 Slowly add to the aqueous solution, and keep stirring slowly; then add NaNO 2 , urea, NaH 2 PO 4 , glycerin, sodium benzoate, stirring continuously during the adding process; finally add purified water to the total amount of surface-activated penetrating agent to be prepared, and stir evenly. Immerse the parts in the osmotic agent activated at 15°C for 10 minutes. Take out the parts and rinse them with clean water, then hang them into the furnace for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com