Cooling type clapboard for U-shaped stuff back-feeder

A returner and cooling technology, which is applied in the field of solid material return device, can solve the problems of different expansion coefficients between the partition and the shell, easy gaps, and easy damage to the partition, so as to ensure long-term stable operation and prolong service life , The effect of smooth working fluid process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

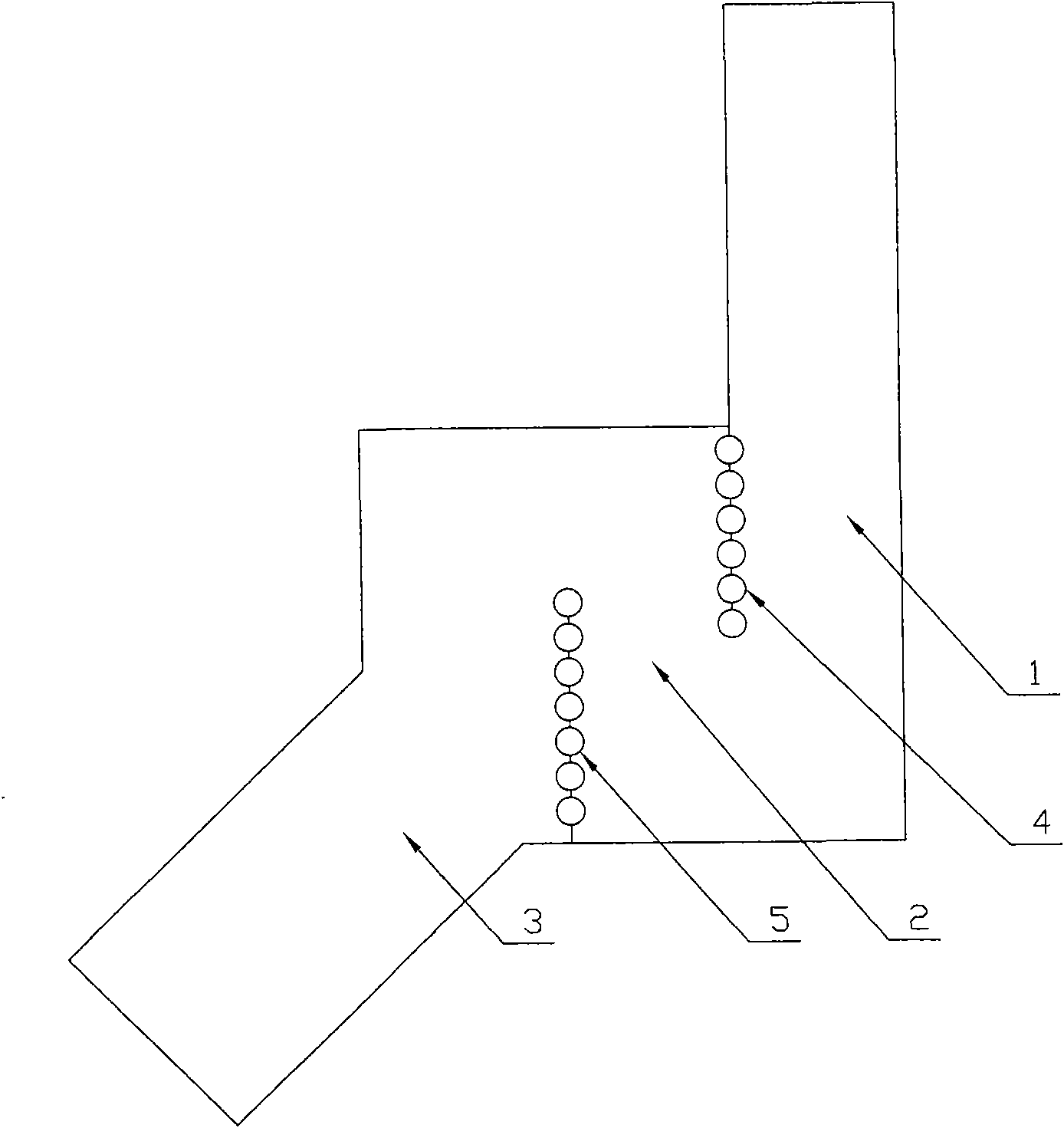

[0046] like figure 1 The U-shaped feeder shown is formed by successively connecting the descending pipe 1, the ascending pipe 2 and the returning pipe 3 with a rectangular cross section; The lower part is connected; there is a return partition 5 between the rising pipe 2 and the return pipe 3, and the upper part of the two is connected; the shell of the return device is made of water-cooled membrane wall tailor-welded, and the inner side is laid with fire-resistant and wear-resistant materials.

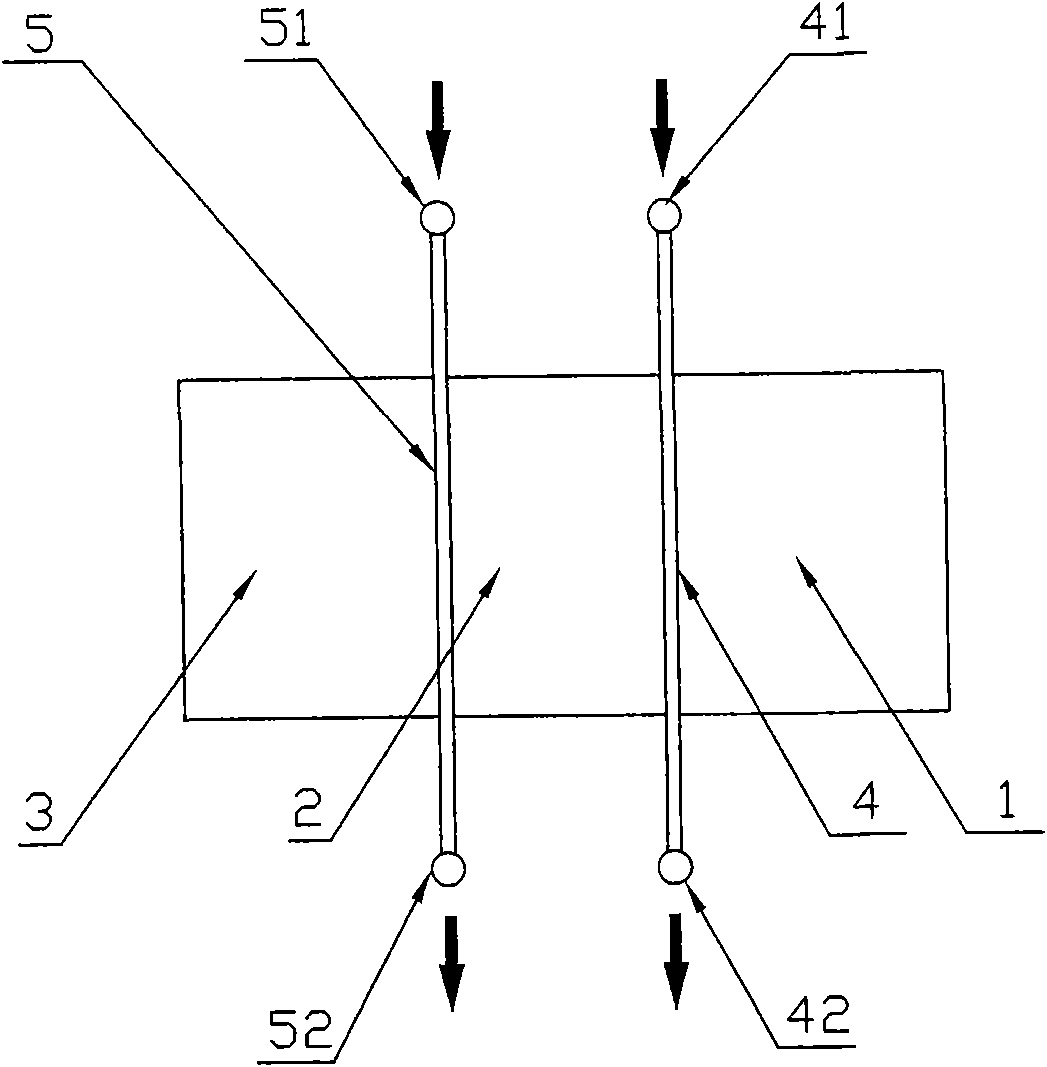

[0047] The intermediate partition 4 and the return partition 5 are composed of horizontally arranged cooling tube bundles, with fins between the tubes, and the cooling tube bundles are coated with fire-resistant and wear-resistant materials. like figure 2 As shown, the cooling tube bundle of the clapboard passes through the tubes on both sides of the shell of the feeder, and is respectively connected with the left and right headers 41, 42 of the middle clapboard and the left and rig...

Embodiment 2

[0051] like figure 1 The U-shaped feeder shown is formed by successively connecting the descending pipe 1, the ascending pipe 2 and the returning pipe 3 with a rectangular cross section; The lower part is connected; there is a return partition 5 between the rising pipe 2 and the return pipe 3, and the upper part of the two is connected; the shell of the return device is made of water-cooled membrane wall tailor-welded, and the inner side is laid with fire-resistant and wear-resistant materials.

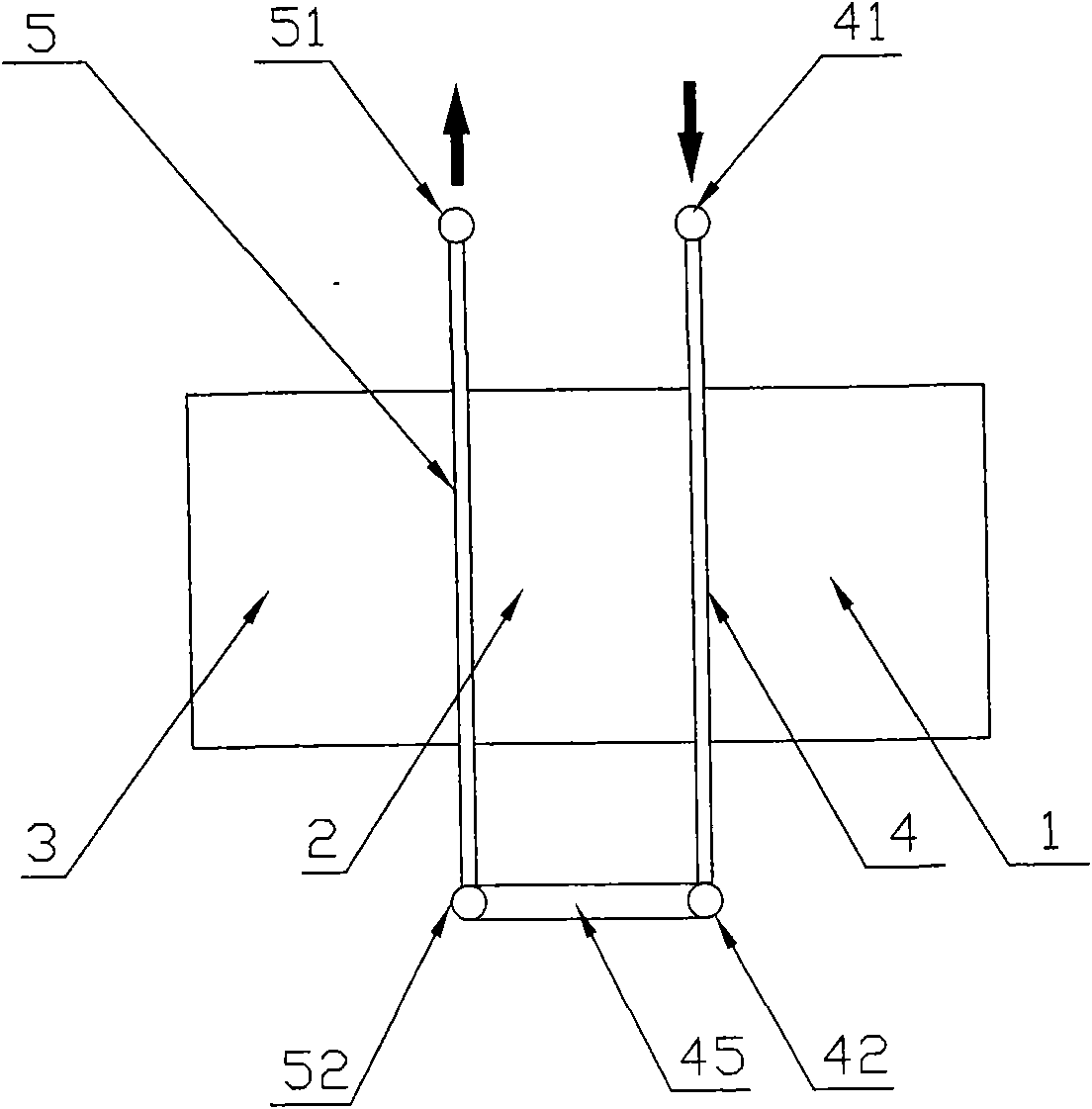

[0052] The middle partition 4 and the return partition 5 are composed of horizontally arranged cooling tube bundles, and there are fins between the tubes. The cooling tube bundles are coated with fire-resistant and wear-resistant materials. like image 3 As shown, the cooling tube bundle of the clapboard passes through the tubes on both sides of the shell of the feeder, and is respectively connected with the left and right headers 41, 42 of the middle clapboard and the left and right...

Embodiment 3

[0055] like Figure 4 The U-shaped feeder shown is formed by successively connecting the descending pipe 1, the ascending pipe 2 and the returning pipe 3 with a rectangular cross section; The lower part is connected; there is a return partition 5 between the rising pipe 2 and the return pipe 3, and the upper part of the two is connected; the shell of the return device is made of water-cooled membrane wall tailor-welded, and the inner side is laid with fire-resistant and wear-resistant materials.

[0056] The intermediate partition 4 and the return partition 5 are composed of horizontally arranged cooling tube bundles, with fins between the tubes, and the cooling tube bundles are coated with fire-resistant and wear-resistant materials. like Figure 5 and Image 6 As shown, the cooling tube bundles of the two partitions pass through the tubes on both sides of the returner shell, and the left ends merge into the left header 451 located on the left side outside the feeder shell,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com