Manufacturing method of anti-curl collar

A manufacturing method and collar technology, which are applied in the field of making anti-curling collars, can solve the problems of increased thickness of the collar tip, hard hand feeling, inability to lift, etc., and achieve the effects of good anti-curling effect and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

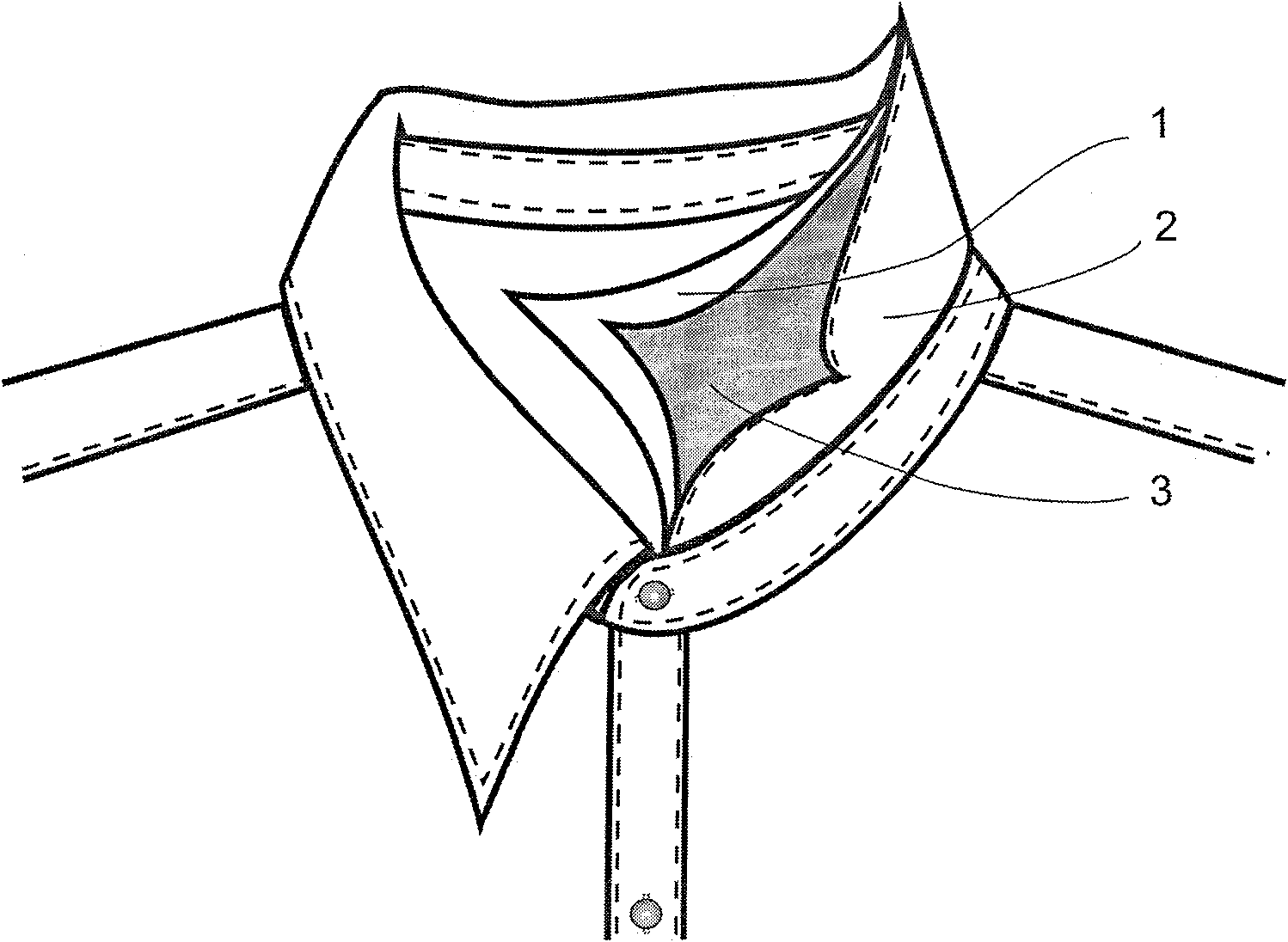

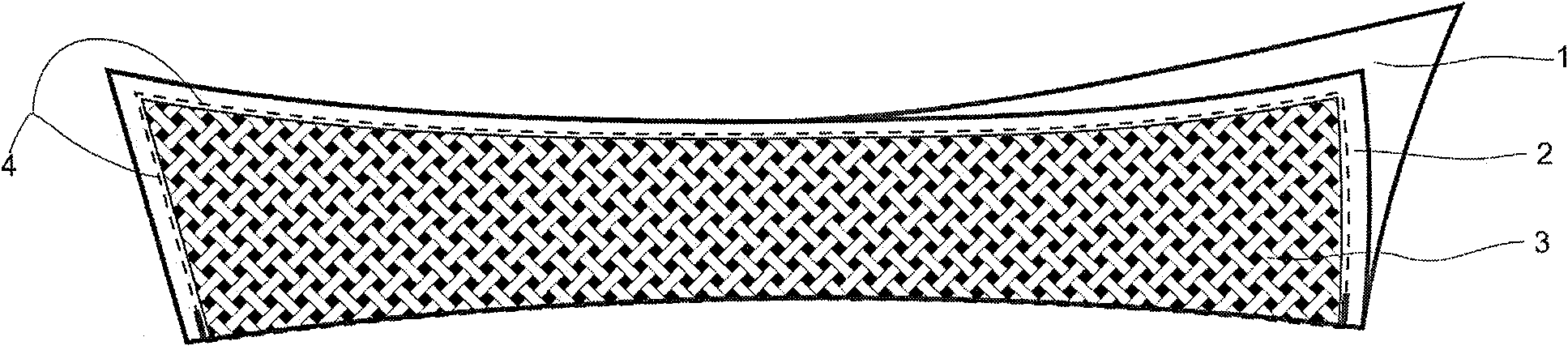

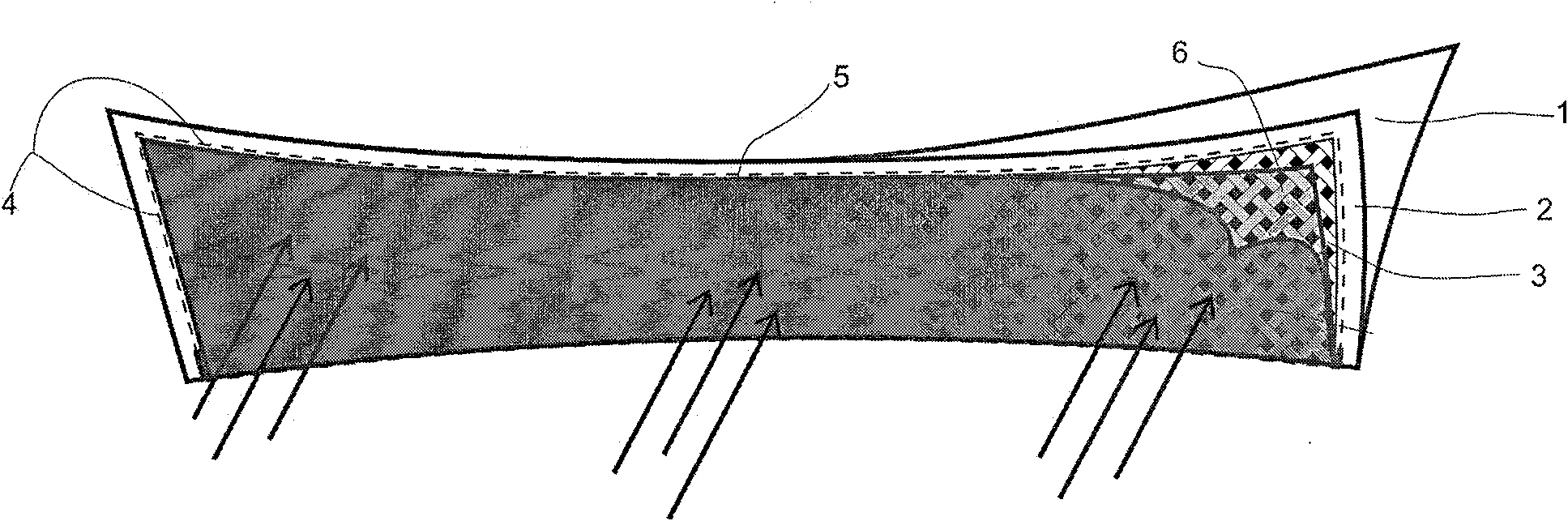

[0028] refer to figure 1 , there is an interlayer 3 between the collar 1 and the collar 2, refer to figure 2 , when manufacturing, the interlayer 3 is first bonded to the collar 2 under the conditions of 165°C, 12 seconds, and 5.0 bar, see image 3 , on one surface of the sheet-shaped thermoplastic adhesive material 6, a layer of high-temperature-resistant non-adhesive material 5 is laminated, and the other side of the thermoplastic adhesive material 6 is placed on the interlayer 3, and ironed at a temperature of 90°C-150°C 2-10 seconds, the thermoplastic adhesive material 6 initially melts, infiltrates the interlayer 3, and initially bonds with the interlayer 3; refer to Figure 4 , peel off the high temperature resistant non-adhesive material layer 5, make the thermoplastic adhesive material 6 one surface Figure 5 nudity shown, see Figure 6 , transport the lapel surface 2 and the collar lining 1, so that the interlayer 3 and the thermoplastic adhesive material 6 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com