Device for analyzing oxygen density and flow rate and analysis method thereof

A technology of oxygen concentration and analysis method, applied in the field of oxygen analysis, can solve the problems of inability to monitor ultrasonic waves at the same time, large monitoring errors, etc., and achieve the effects of avoiding the decline of measurement accuracy, fast response speed and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

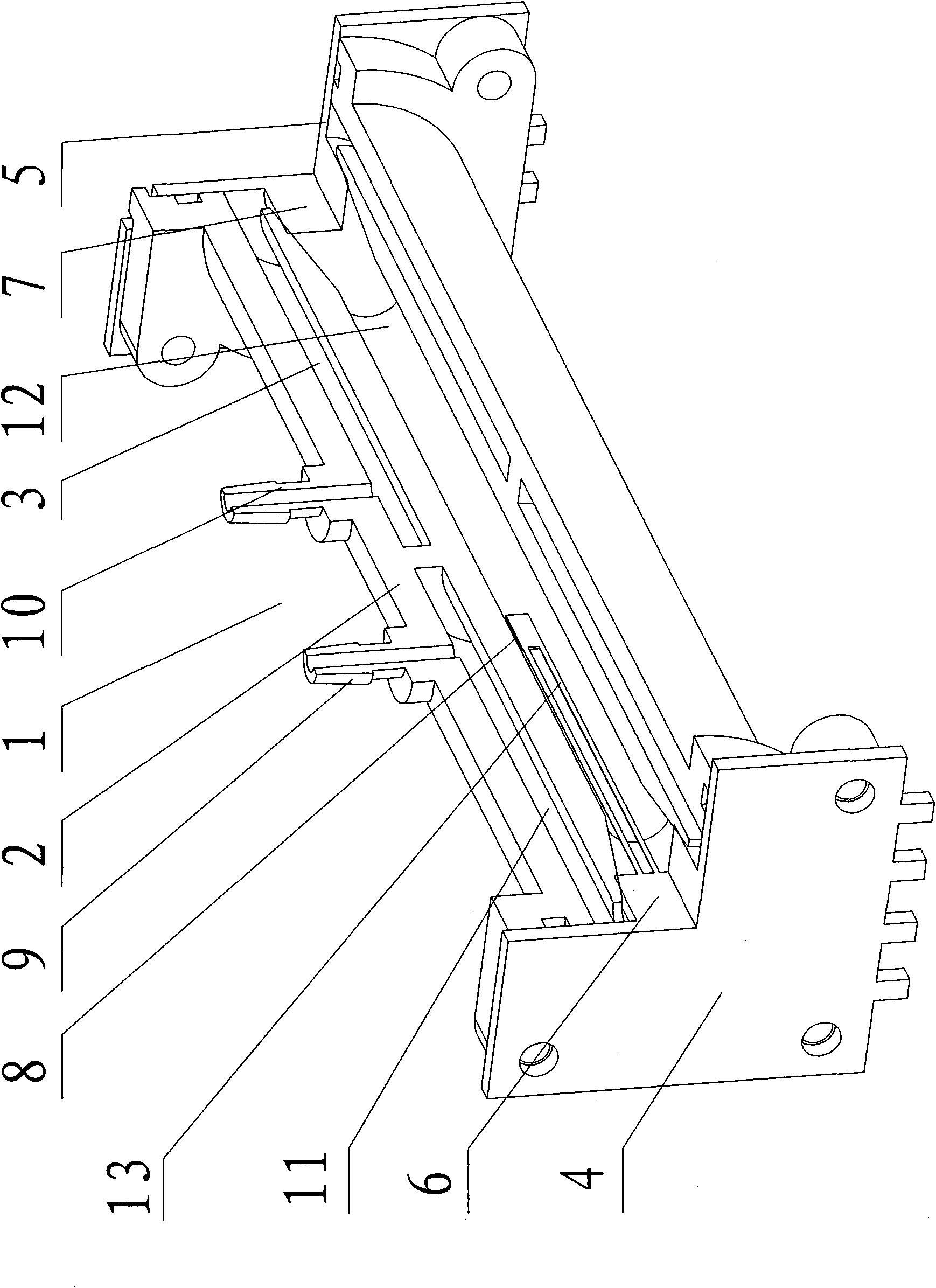

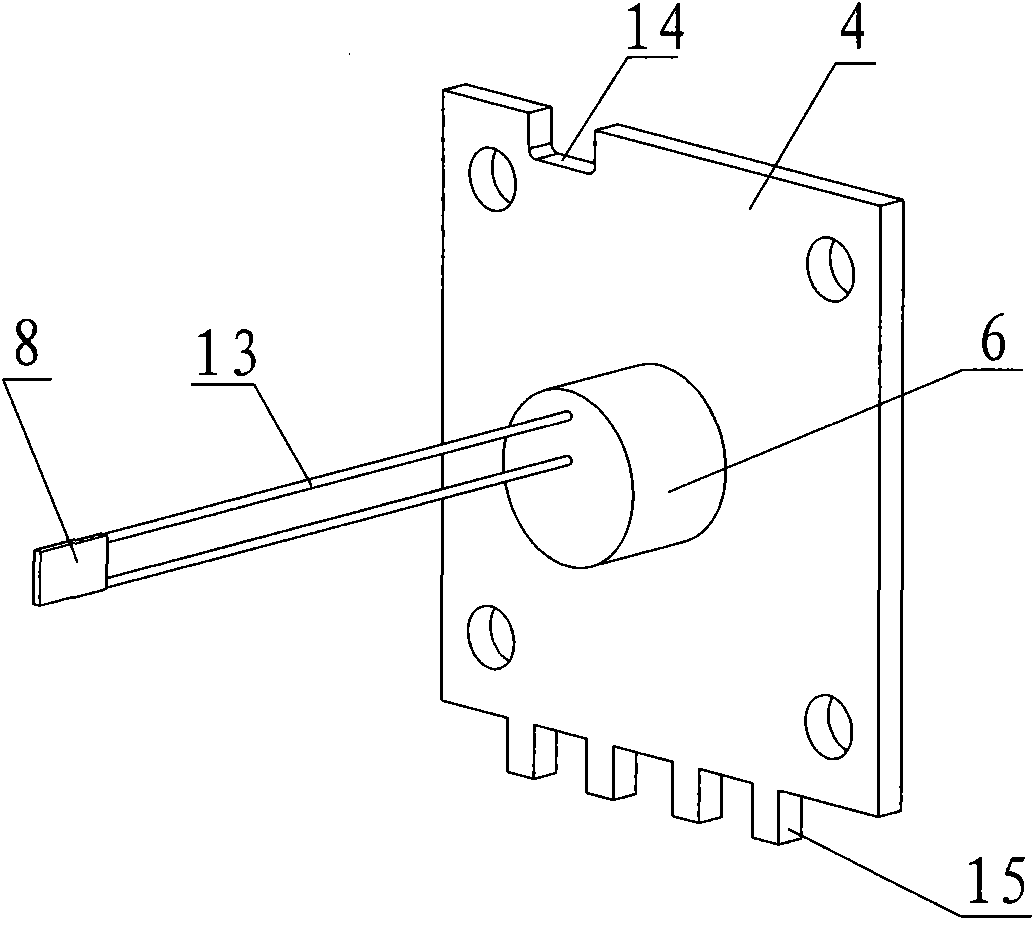

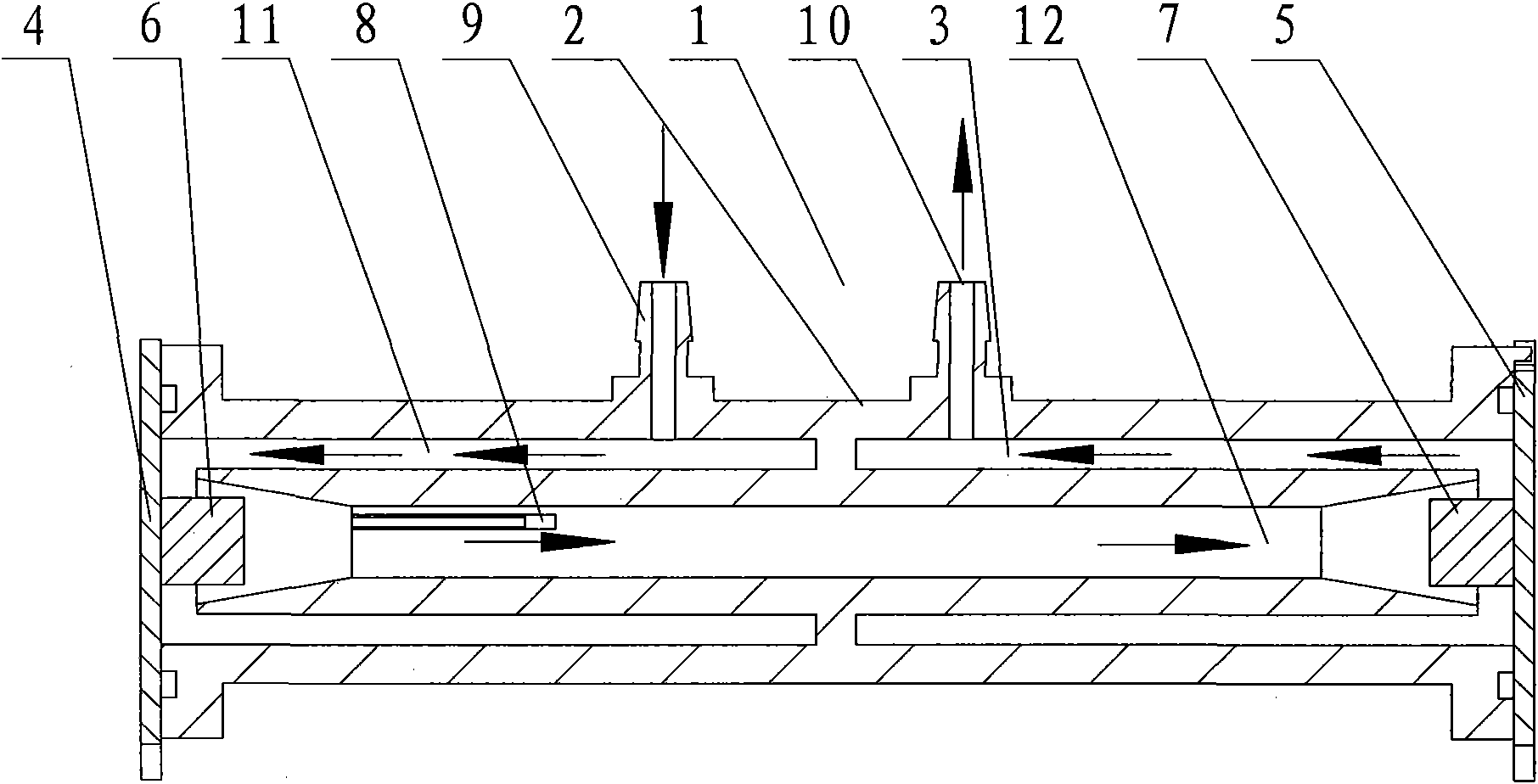

[0026] Such as figure 1 , image 3 and Figure 4 As shown, the device for analyzing oxygen concentration and flow rate of the present invention includes a sensor unit 1 and a signal processing control circuit. The sensor unit 1 includes a container 2 and the first and second circuit boards 4, 5 installed at both ends of the container 2. The container 2 of the present embodiment is cylindrical and 11 centimeters long; the container 2 has a cylindrical container cavity 12, The axial cross-sections of its two ports are trapezoidal; in the container 2, there are respectively inlet and outlet outer cavities 11,3, both of which are respectively arranged along the circumferential direction outside the container inner cavity 12, and the inlet and outlet outer cavities 11,3 The adjacent ends are all closed ends, and the other end communicates with the inner cavity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com