Dual-yoke type heavy steel pile trolley for cutter suction dredge

A technology of cutter suction dredger and steel pile trolley, which is applied in the device field of marine engineering technology, can solve problems such as increased external force of the trolley system, inability to adapt the trolley system, and increased track deformation, and achieve load-carrying Large force, strong track deformation adaptability, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

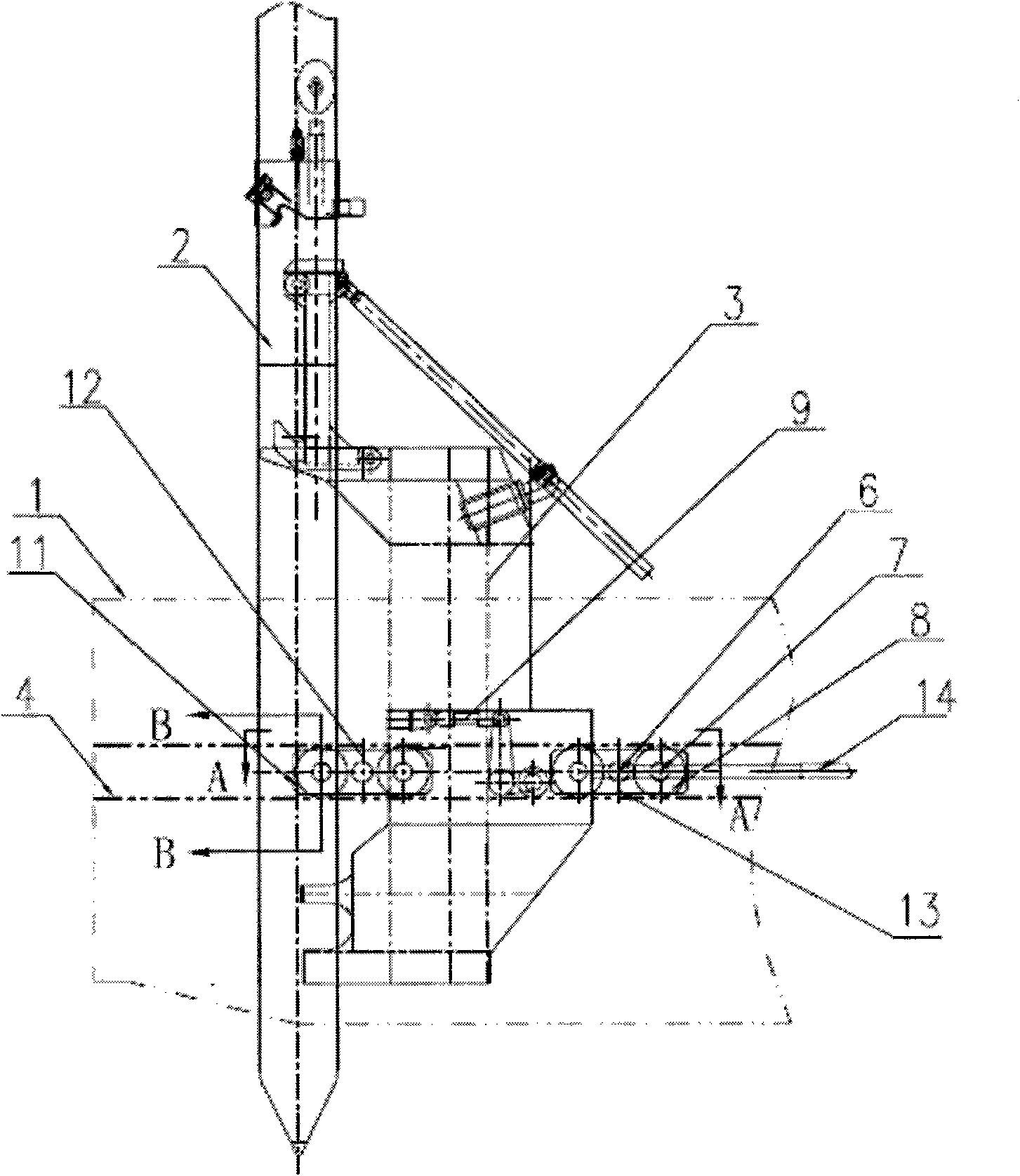

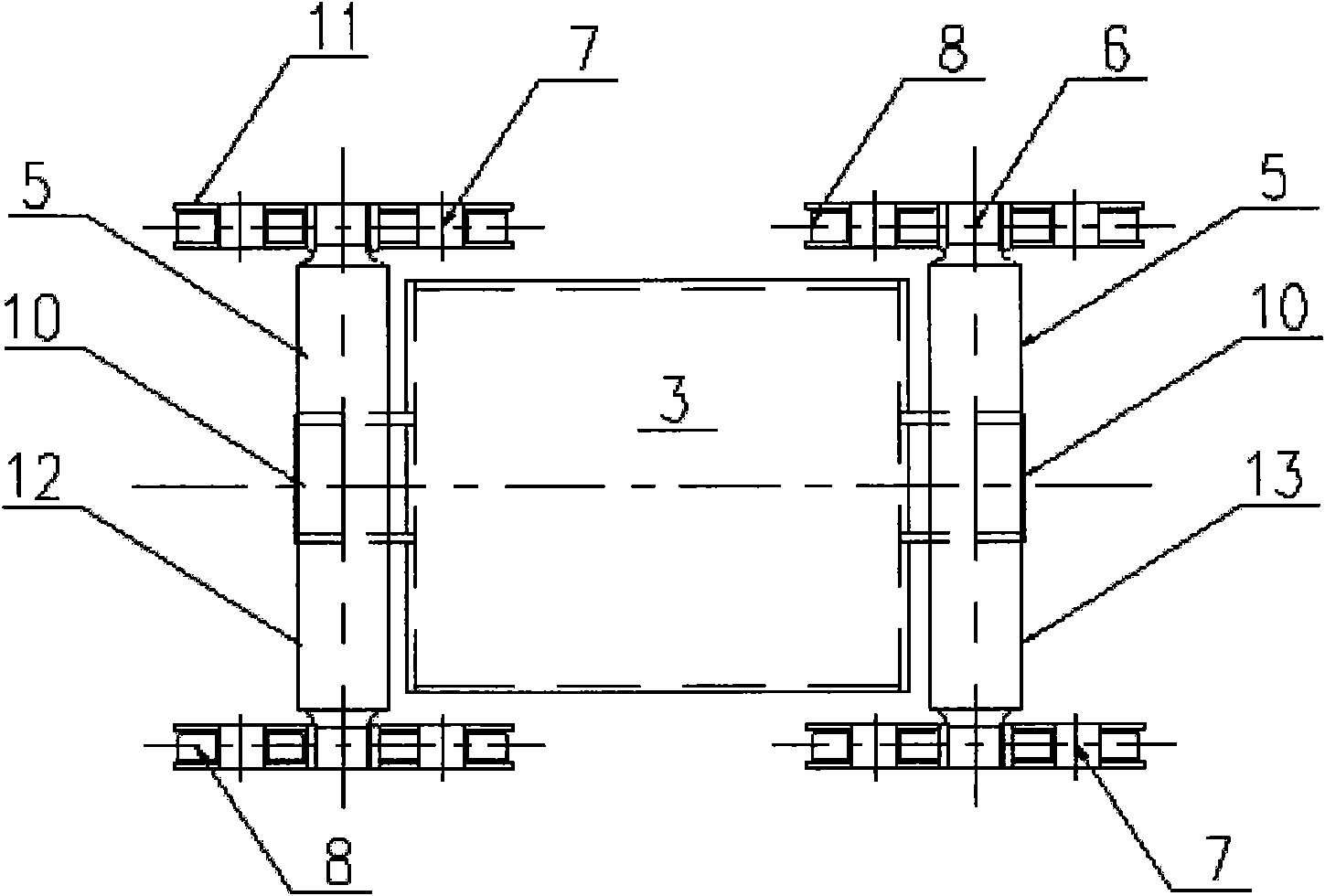

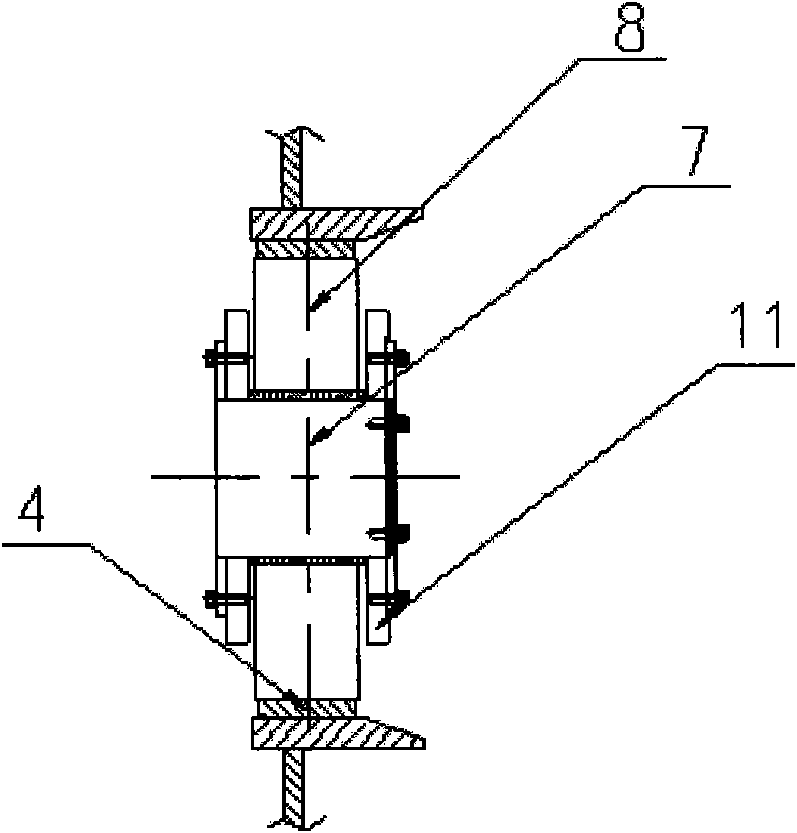

[0023] Such as figure 1 , figure 2 and image 3 As shown, this embodiment includes: hull 1, steel pile 2, trolley main structure 3, track 4, balance beam 5, wall frame rotating shaft 6, roller rotating shaft 7, walking roller 8, buffer device 9, balancing beam rotating shaft 10, Roller wall frame 11, first traveling yoke 12, second traveling yoke 13, and traveling oil cylinder 14. The first walking yoke 12 is exactly the same as the second walking yoke 13, and the walking yoke includes four identical walking rollers 8, roller rotating shaft 7, wall frame rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com