Method for removing salt in betaine solution

A betaine and solution technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of large power consumption, harsh process control, increase solvent loss, etc., and achieve less material loss and yield. High, process water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

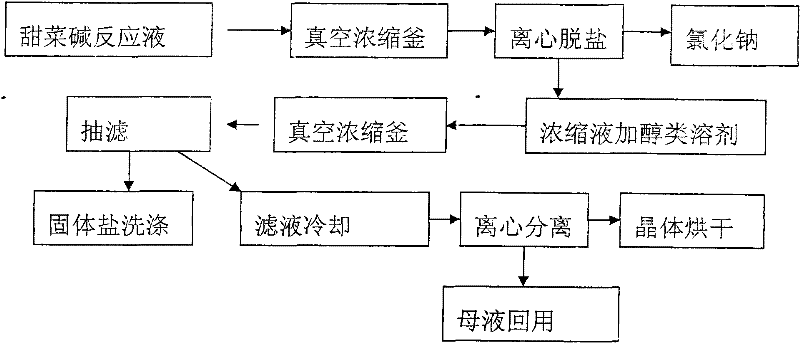

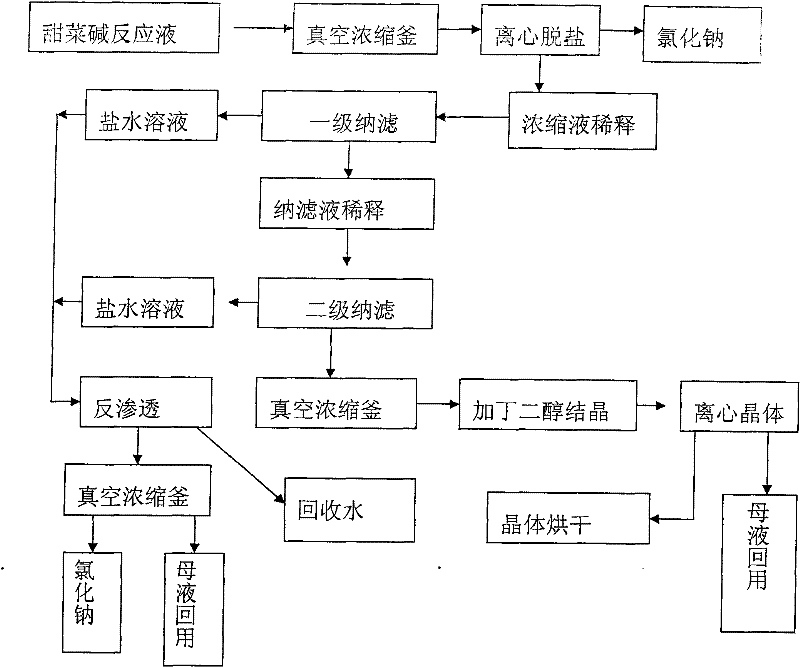

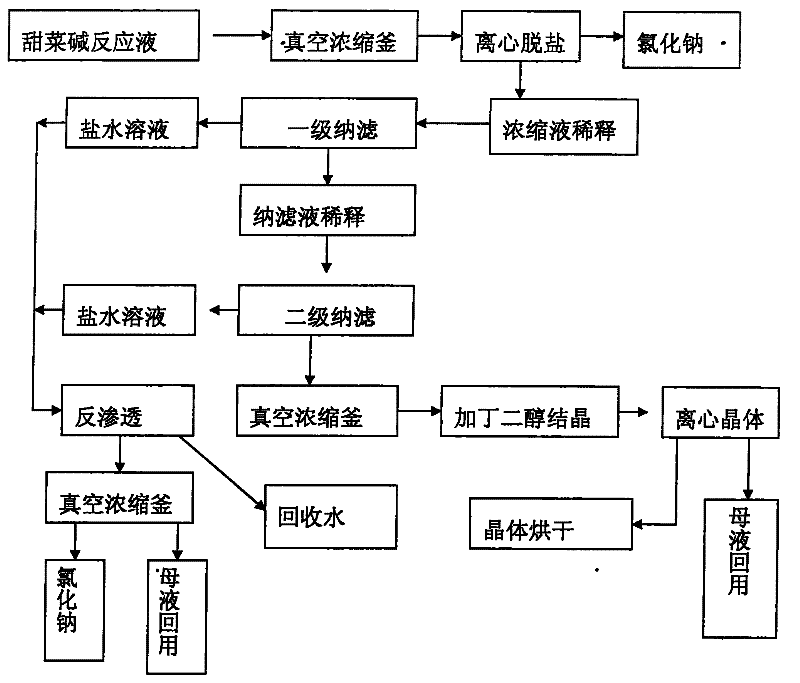

Method used

Image

Examples

Embodiment 1

[0019] The heat exchanger adopts a stainless steel tube heat exchanger, a tubular semi-permeable membrane (GEDK4040 type), and a stainless steel material tank. First, the betaine solution synthesized with chloroacetic acid, sodium carbonate, and trimethylamine is concentrated to remove 70wt% of salt , then dilute the concentrated betaine solution to 15% (mass percentage concentration), and circulate it under the control of a flow meter with a multistage pump. In the tank, the brine solution that passes through the semipermeable membrane enters the brine collection tank for recovery. When the conductivity of the betaine solution in the stainless steel material tank reaches 7000μs / cm, the betaine solution in the material tank is pumped into the secondary semi-permeable membrane circulation tank for circulation treatment, and the temperature is controlled at about 50°C. Circulation treatment, when the conductivity reaches the required 700μs / cm, the treatment ends, and the materia...

Embodiment 2

[0021] The heat exchanger adopts a stainless steel tube heat exchanger, a plate-and-frame semi-permeable membrane (GEDK4040 type), and a stainless steel material tank. First, the betaine solution synthesized with chloroacetic acid, sodium carbonate, and trimethylamine is concentrated to remove 70wt% of the betaine. Salt, then the betaine concentrated solution is diluted to 12% (mass percentage concentration), circulates under flow meter control with a multistage pump, and the solution enters the semi-permeable membrane after passing through the heat exchanger, and the temperature is controlled at 60 ° C, and then returns to In the material tank, the brine solution passing through the semi-permeable membrane enters the brine collection tank for recovery. After the conductivity of the betaine solution in the stainless steel material tank reaches 8000μs / cm, the betaine solution in the material tank is pumped into the secondary semi-permeable membrane circulation tank for circulati...

Embodiment 3

[0023] The heat exchanger adopts a stainless steel tube heat exchanger, a spiral-wound semi-permeable membrane (GEDK4040 type), a stainless steel material tank, and dilutes the betaine concentrated solution to the required concentration of 10%, and uses a multi-stage pump to carry out under the control of a flow meter. Circulation, the solution enters the semi-permeable membrane after passing through the heat exchanger, the temperature is controlled at 65°C, and then returns to the material tank, and the brine solution that passes through the semi-permeable membrane enters the brine collection tank for recovery. After the conductivity of the betaine solution in the stainless steel material tank reaches about 7500μs / cm, the betaine solution in the material tank is pumped into the secondary semi-permeable membrane circulation tank for circulation treatment, and the temperature is controlled at about 55°C. Carry out cyclic treatment, when the conductivity reaches the required 800μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com