Method for manufacturing bar code on x-ray film

A technology of barcode and light film, applied in the field of X-ray film, can solve the problems of inability to achieve automation and lagging technical means, and achieve the effect of improving scalability and processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] like figure 1 As shown, a method for making a barcode on an X-ray film of the present invention, in the process of making an X-ray film, the barcode image containing the file directory number or information is made on the X-ray film together to become an X-ray film with a barcode . Use a barcode reader to scan the barcode on the X-ray film and get the information contained in it, so that the data can be collected automatically, the process of manual operation is eliminated, and the work intensity and error rate of the input process are greatly reduced.

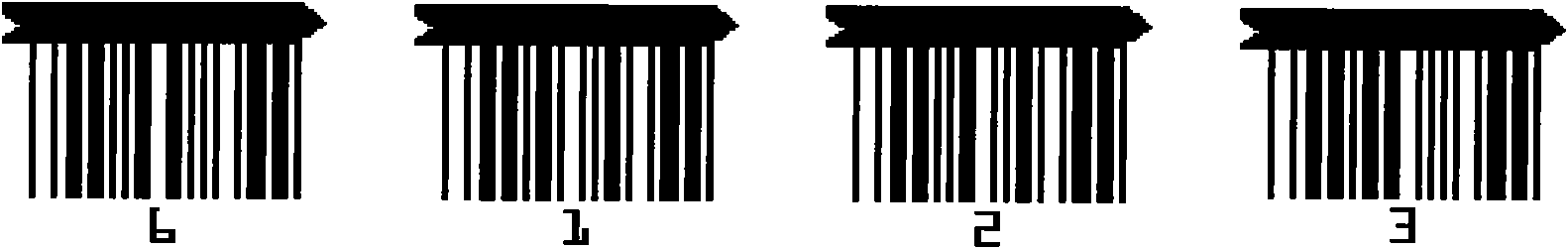

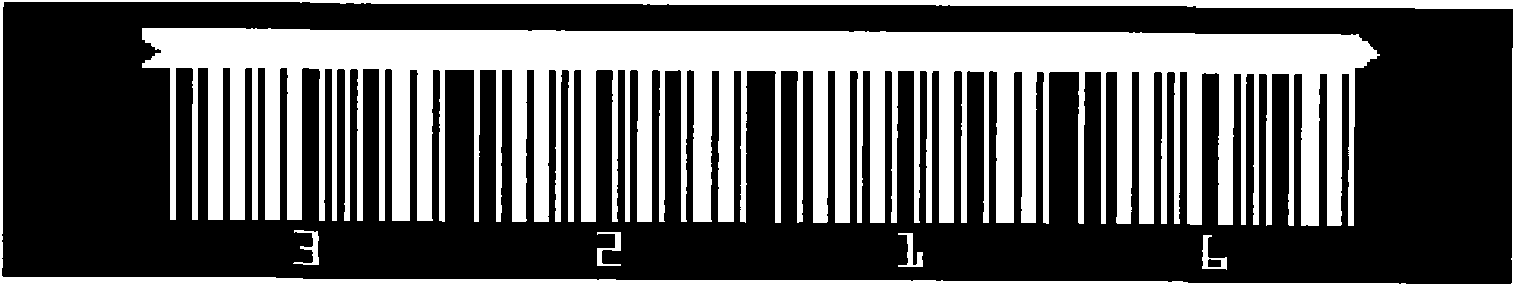

[0015] In the method for making barcodes on X-ray films of the present invention, the production of barcodes on X-ray films: through the prepared metal barcode units, such as CODE39 codes or CODABAR codes, the completed metal barcode units are arranged according to the content of information characters After splicing and splicing, a set of metal unit barcodes is formed. When the X-ray film is taken, the image of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com