Optical fibre sensor structure

An optical fiber sensor and optical fiber technology, applied in the field of optical measurement, can solve the problems of low sensitivity, complex sensor measurement system and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

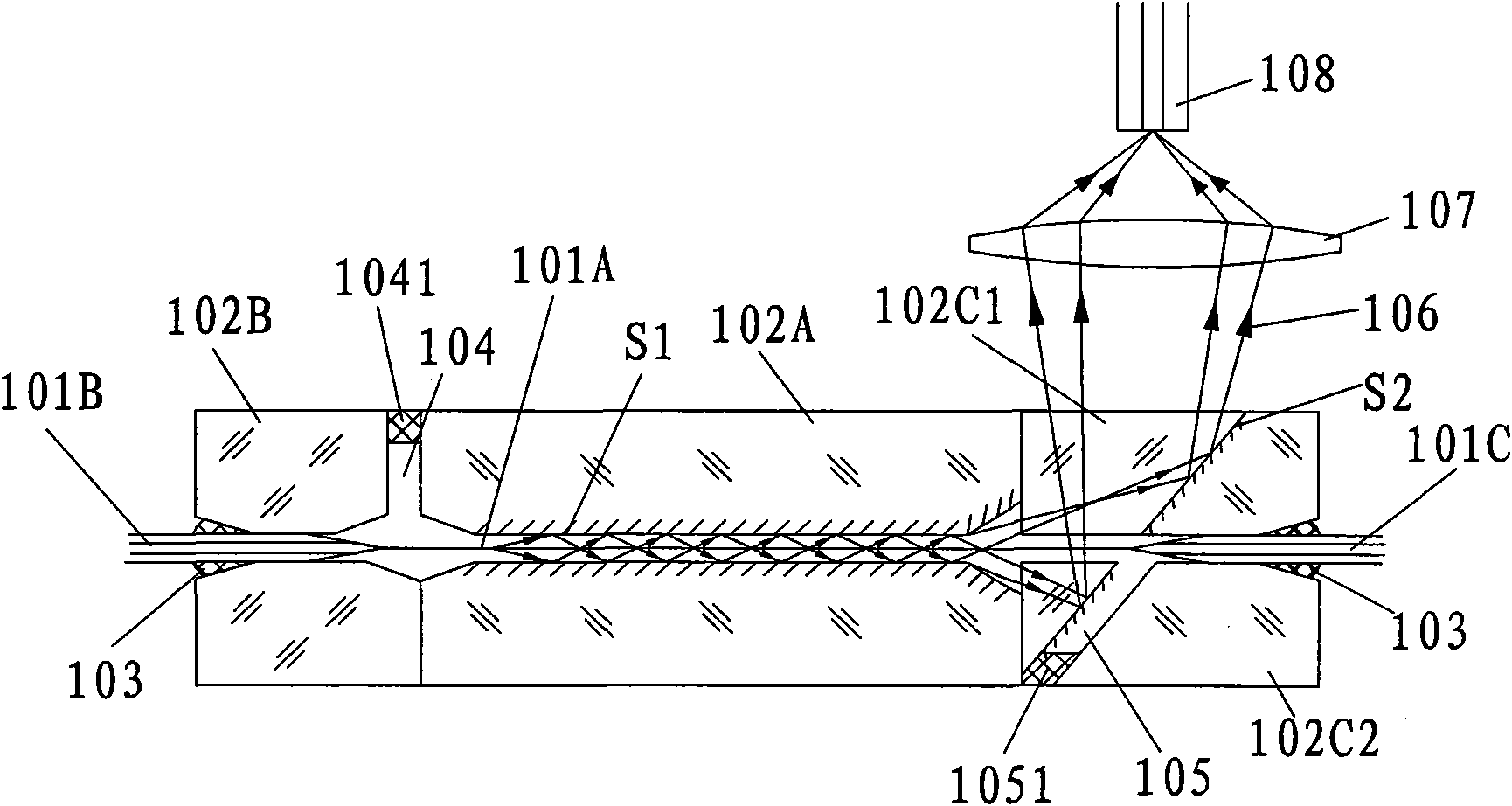

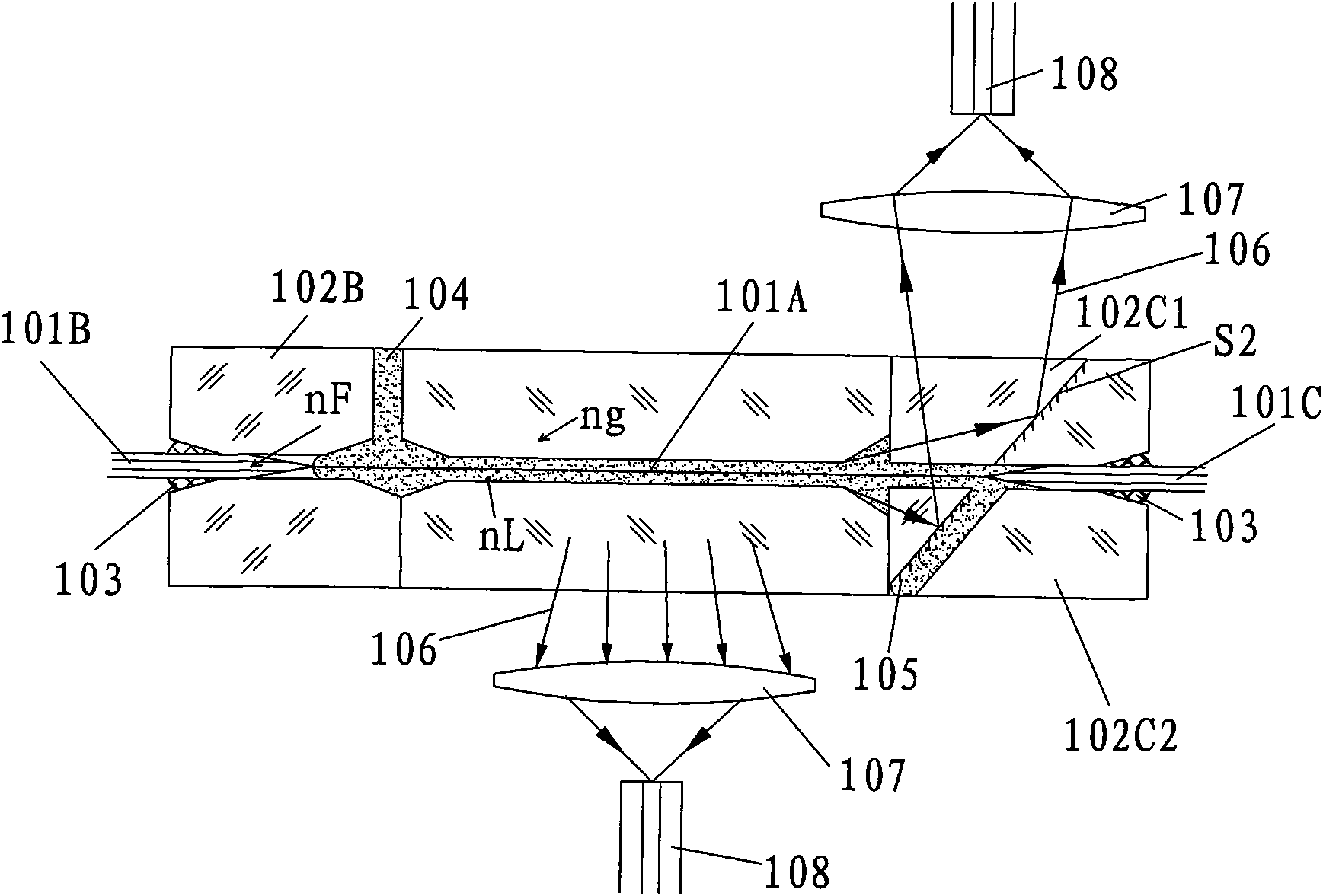

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0023] In the optical fiber sensor structure of the present invention, the laser is input through the optical fiber, and the evanescent wave generated by the laser in the optical fiber excites the surrounding gas or liquid substance, and the obtained fluorescence or Raman light is collected, and then passed through The spectrometer performs spectrum analysis and processing to obtain detection results.

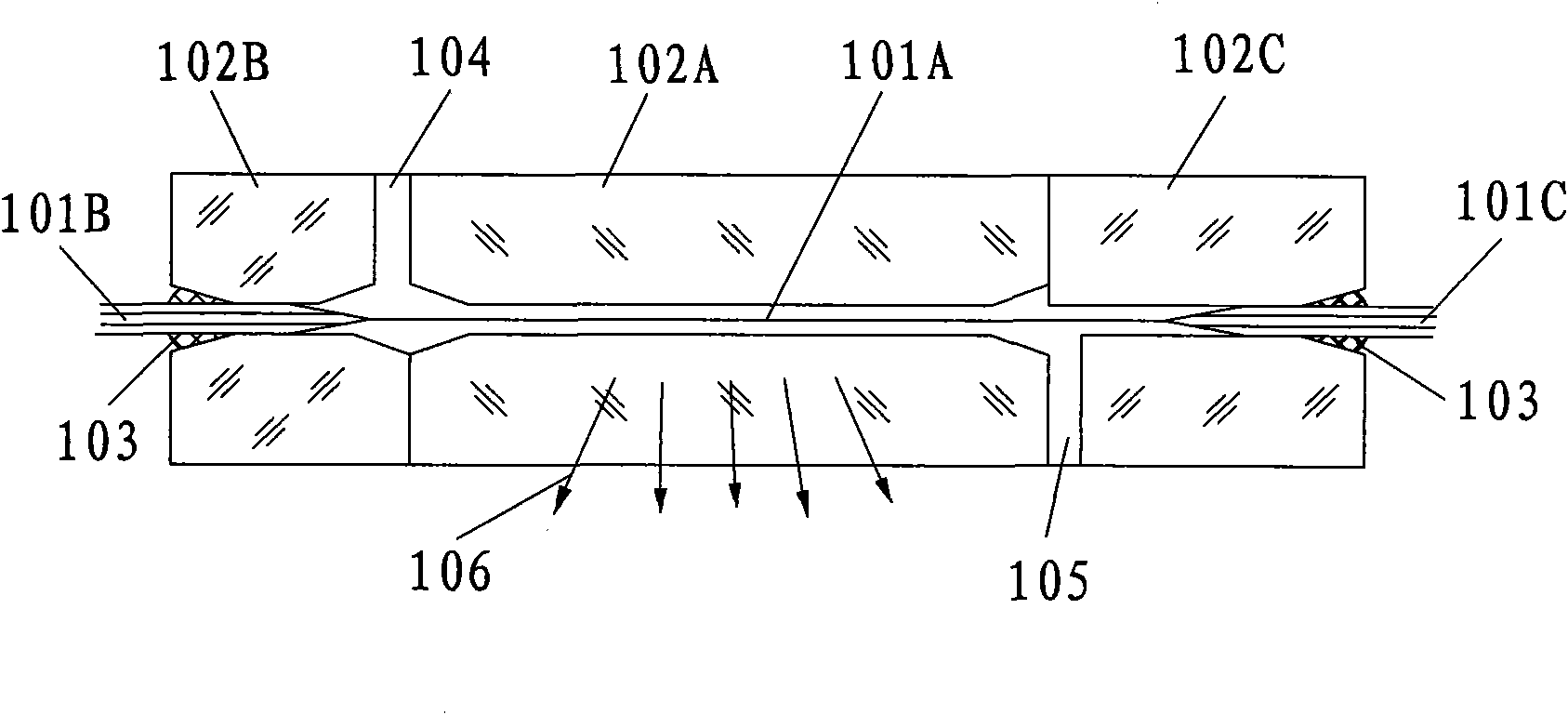

[0024] refer to figure 1 In the shown embodiment one, 101A is a conventional section of an optical fiber, 101B and 101C are tapered sections of an optical fiber, 102A, 102B, and 102C are three-section fiber capillary sleeves, and 104 and 105 are respectively an inlet channel and an outlet channel, 103 is the glue for bonding the tapered sections 101B, 101C of the filling fiber and the fiber capillary sleeves 102B, 102C, and 106 is the fluorescence or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com