Anti-force type large-size sludge solidifying and compressing tester

A sludge solidification and compression test technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of poor effect, small sample size, and few drainage paths, and achieve reasonable evaluation, large size, and drainage The effect of multiple paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

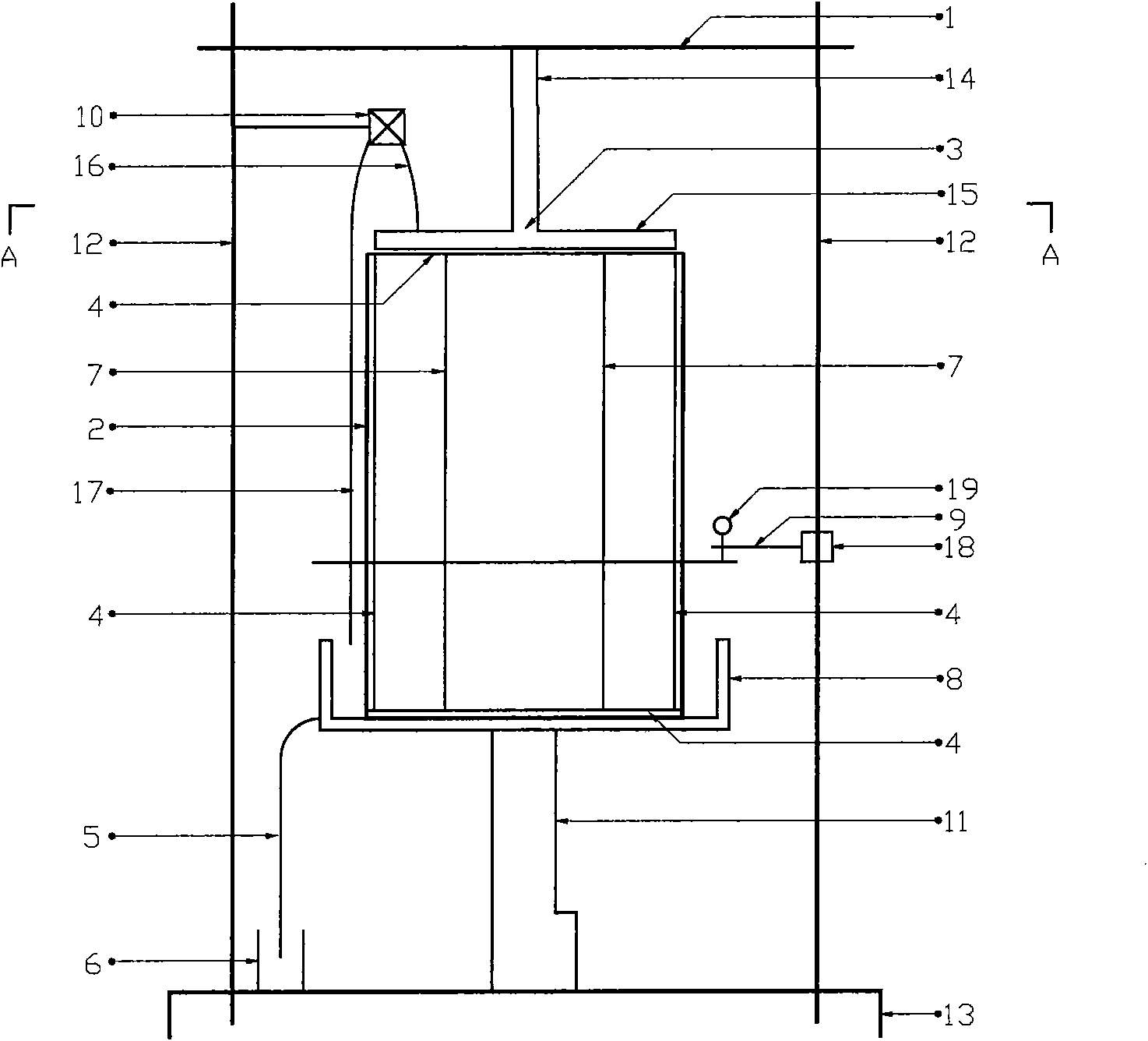

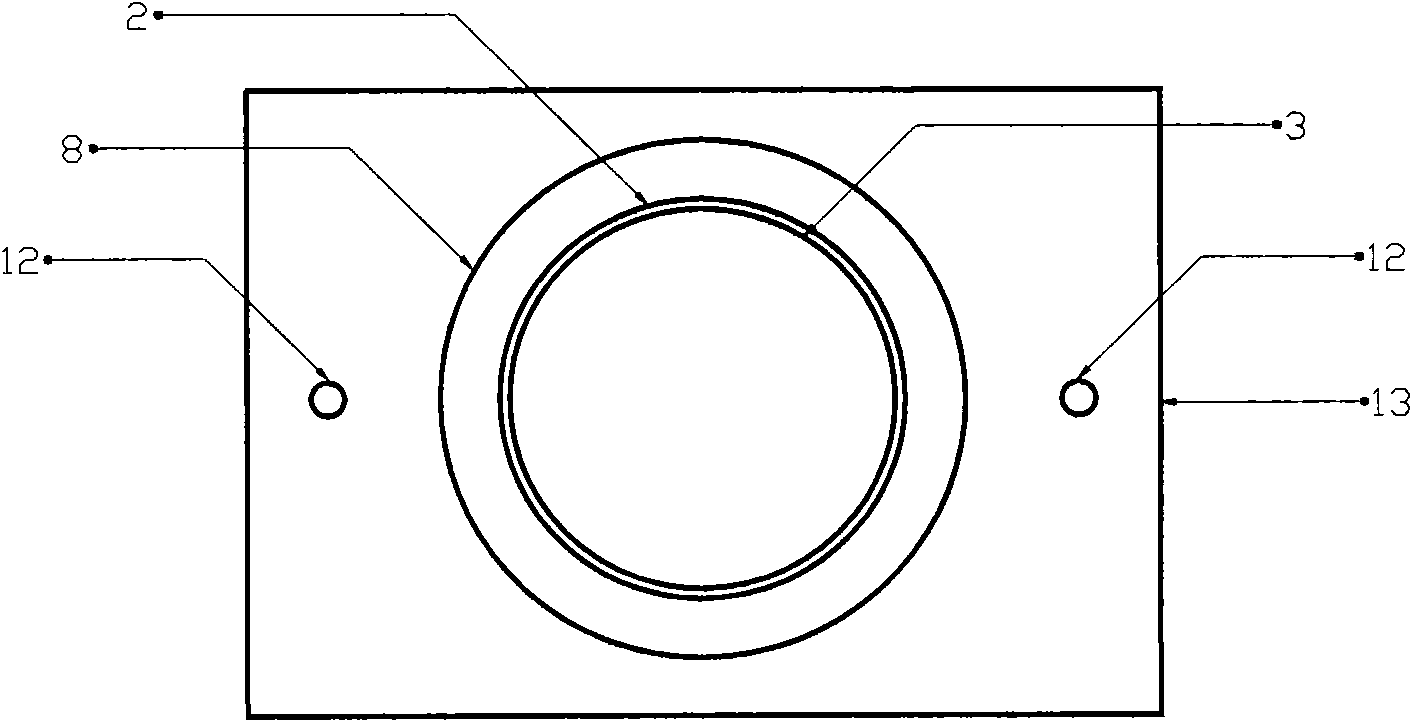

[0019] Embodiment 1, the top plate 1 is made of steel, with a length of 800 mm, a width of 500 mm, and a thickness of 20 mm. A circular hole with a diameter of 20 mm is left at the center of 100 mm from both ends of the top plate to fix the column 12 , there is also a circular hole with a diameter of 25 mm in the middle of the top plate 1, which is used to fix the connecting rod 14; the length of the column 12 is 1400 mm, and the diameter is 20 mm. The two ends of the column 12 are threaded, and there is a column on each side of the instrument. 12; The pressure piston 3 is composed of a connecting rod 14 and a compression disc 15. The length of the connecting rod 14 is 300 mm and the diameter is 25 mm. The diameter of the compression disc 15 is 390 mm and the thickness is 20 mm. A vertical hole with a diameter of 2 mm is used for drainage, and the connecting rod 14 and the compression plate 15 are welded together; the outer diameter of the compression container 2 is 430 mm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com