Preloading type sludge solidification compression tester

A sludge solidification and compression test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of few drainage paths, small sample size, poor effect, etc., and achieve many drainage paths, large size, The effect of reasonable evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

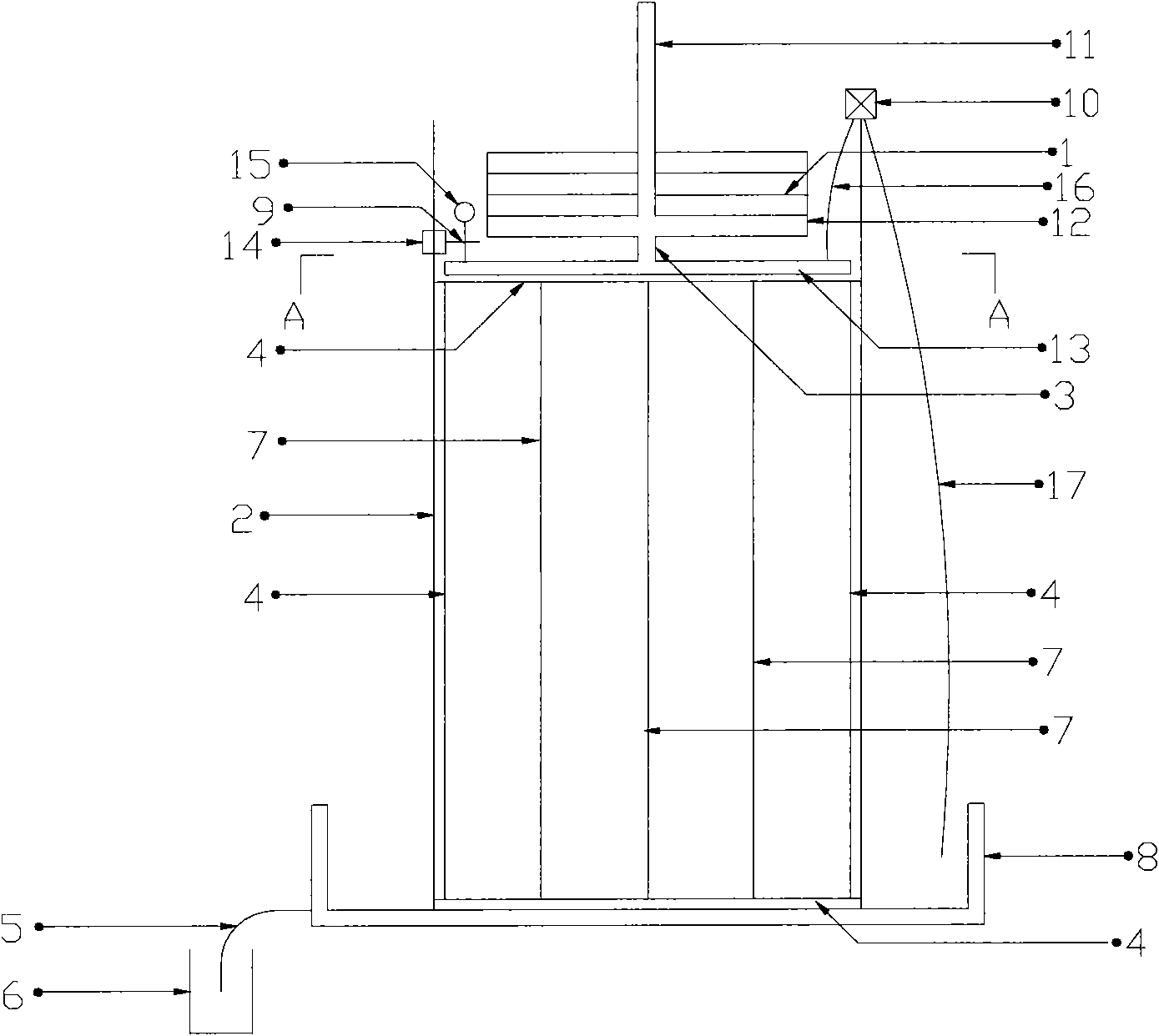

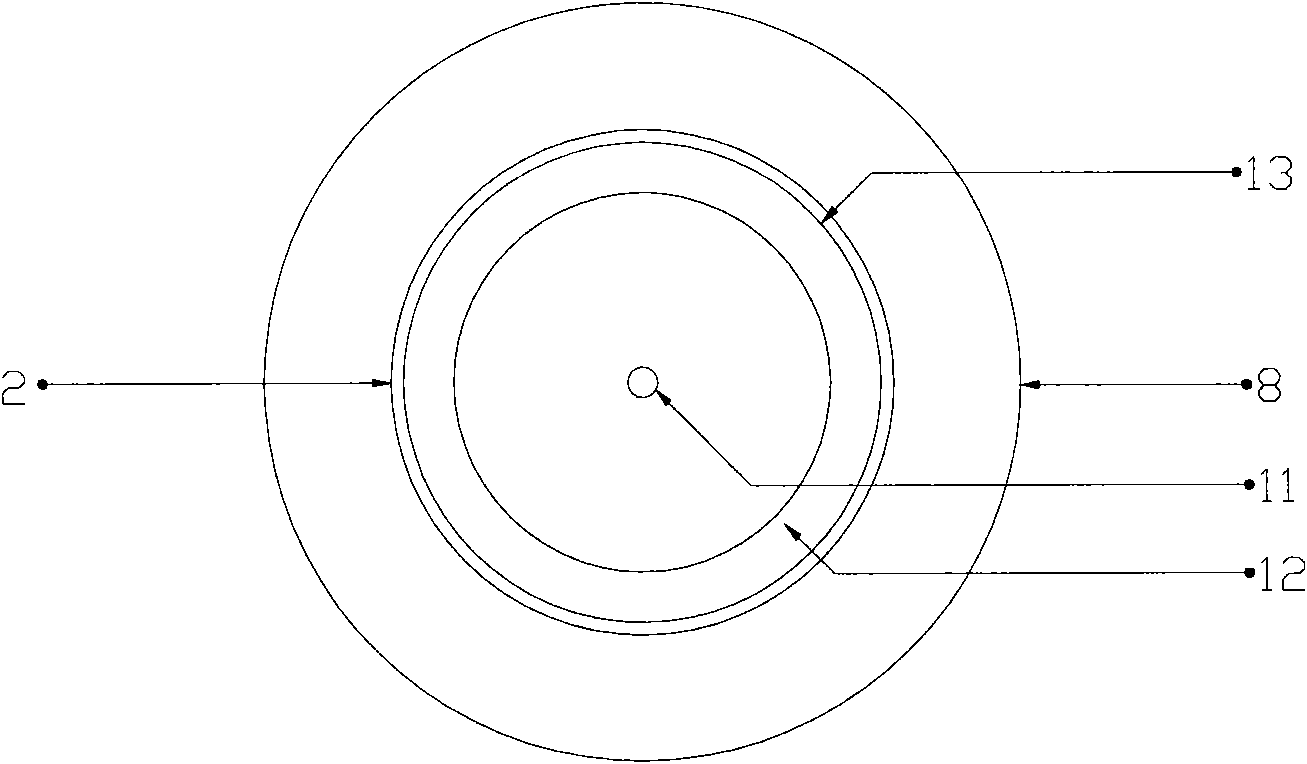

Embodiment 1

[0017] Embodiment 1, the pressurized weight 1 is made up of a plurality of steel plates, and the diameter of each steel plate is 300 millimeters, and the thickness is 20 millimeters, and there is the hole that diameter is 22 millimeters in the center of steel plate, and the two sides of each steel plate have Handle for easy transportation; the pressure piston 3 is composed of a column 11, an upper tray 12 and a lower compression plate 13. The height of the column 11 is 400 mm, and the diameter is 20 mm. The diameter of the lower compression plate 13 is 390 mm, and the thickness is 20 mm. 20 vertical holes with a diameter of 2 mm are evenly distributed on the surface of the disc 13 for drainage. The diameter of the upper tray 12 is 300 mm and the thickness is 20 mm. The column 11 is welded to the Together, the distance between the upper tray 12 and the lower compression plate 13 is 30 mm; the external diameter of the compression container 2 is 440 mm, the height is 850 mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com