Dehydration test instrument of sludge garbage mixture

A mixture and tester technology, applied in presses, manufacturing tools, etc., can solve the problems of few drainage paths, small sample size, poor effect, etc., and achieve the effect of many drainage paths and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

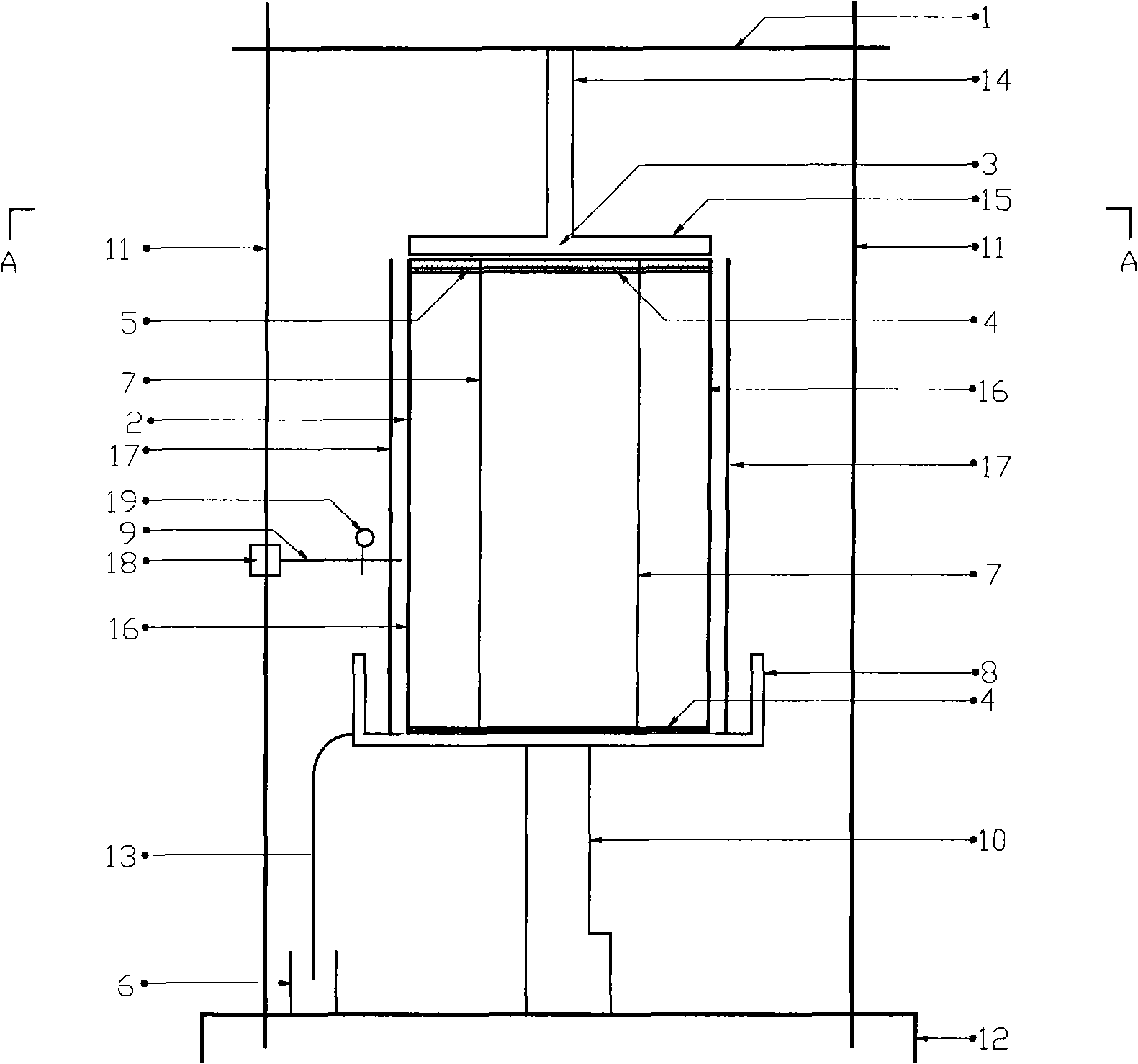

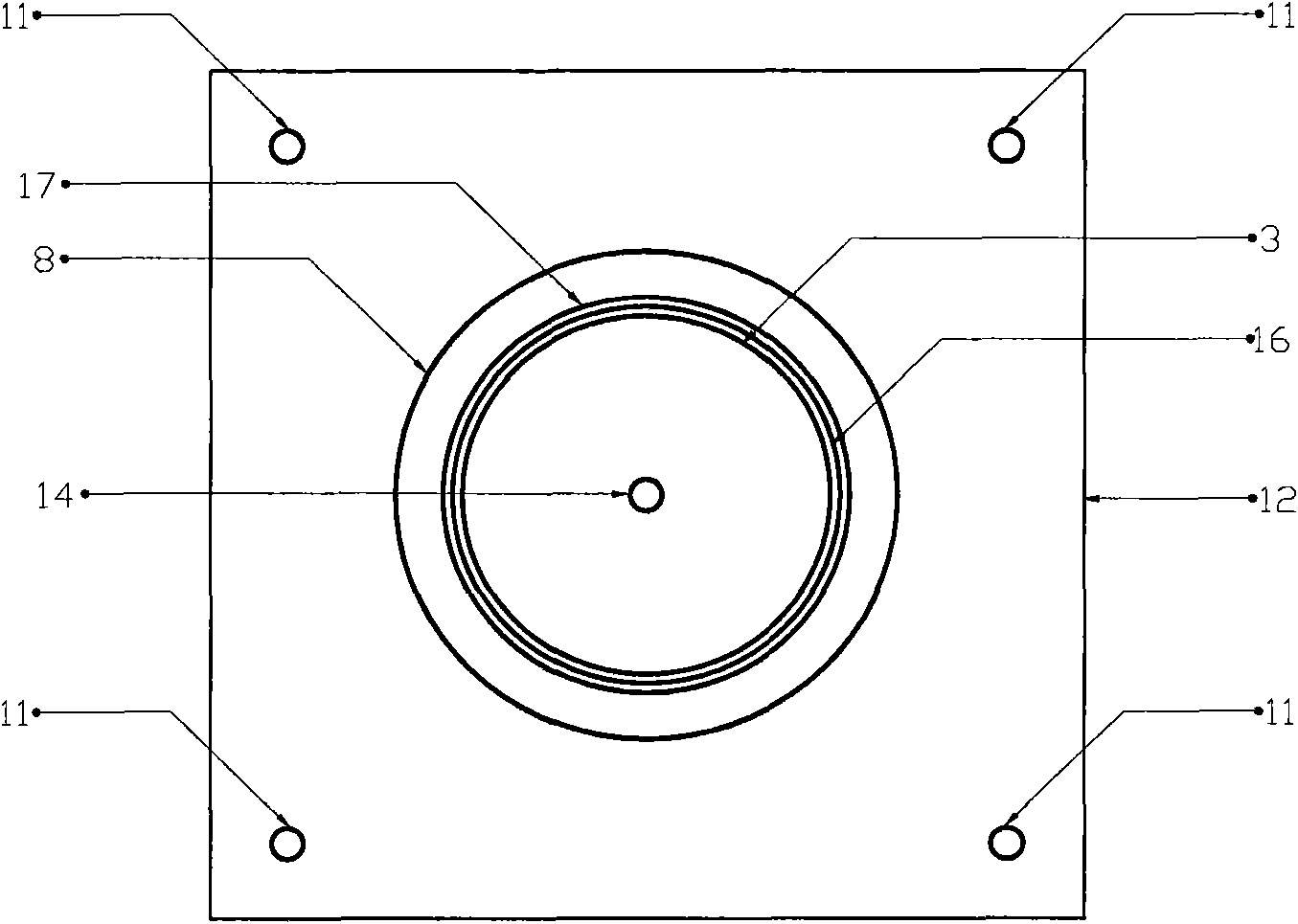

[0019] Embodiment 1, top plate 1 adopts steel to make, and length is 1200 millimeters, and width is 1000 millimeters, and height is 20 millimeters, leaves the circular hole that diameter is 20 millimeters respectively at the four corners that are 100 millimeters away from both sides of top plate, is used for Fix the column 11, and the center of the top plate 1 also leaves a circular hole with a diameter of 25 mm for fixing the connecting rod 14; the length of the column 11 is 1600 mm, and the diameter is 20 mm. The two ends of the column 11 are threaded. Root column 11; Pressure piston 3 is made up of connecting rod 14 and compression disc 15, and connecting rod 14 lengths are 250 millimeters, and diameter is 25 millimeters, and compression disc 15 diameters are 590 millimeters, and thickness is 20 millimeters, and on compression disc 15 evenly distributes 40 vertical holes with a diameter of 2 mm are used for drainage, and the connecting rod 14 and the compression plate 15 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com