Core-shell structured polyvinylidene fluoride/polycarbonate superfine fiber and preparing method thereof

A technology of polyvinylidene fluoride and polycarbonate, applied in fiber processing, filament/wire forming, conjugated synthetic polymer artificial filament, etc. Problems such as adjusting the properties of the spinning solution and not being able to prepare the core/shell structure fibers, etc., to achieve the effect of simple and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

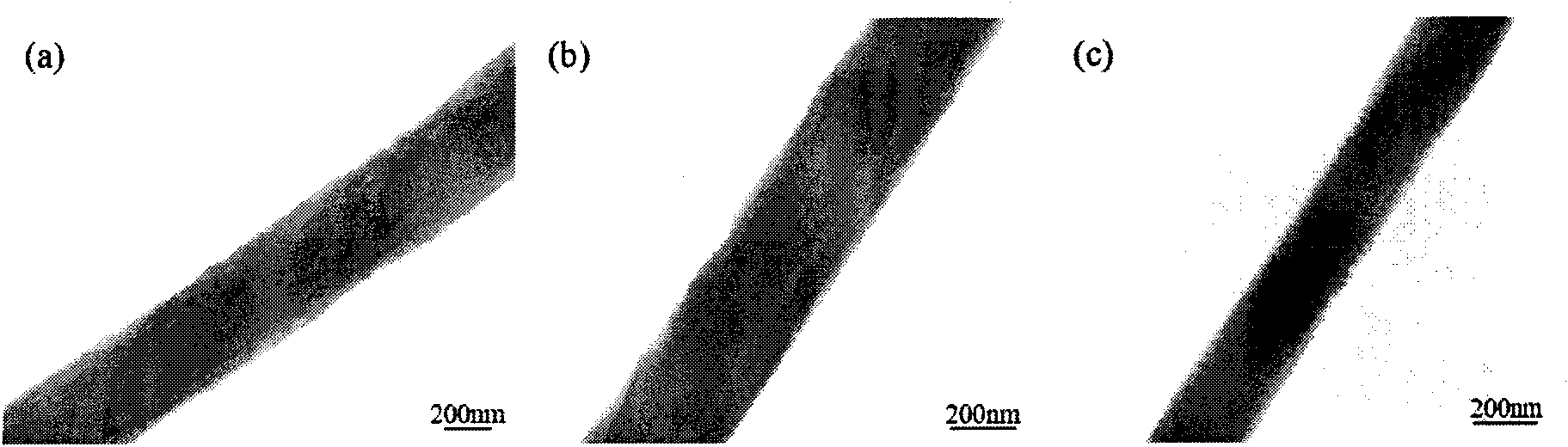

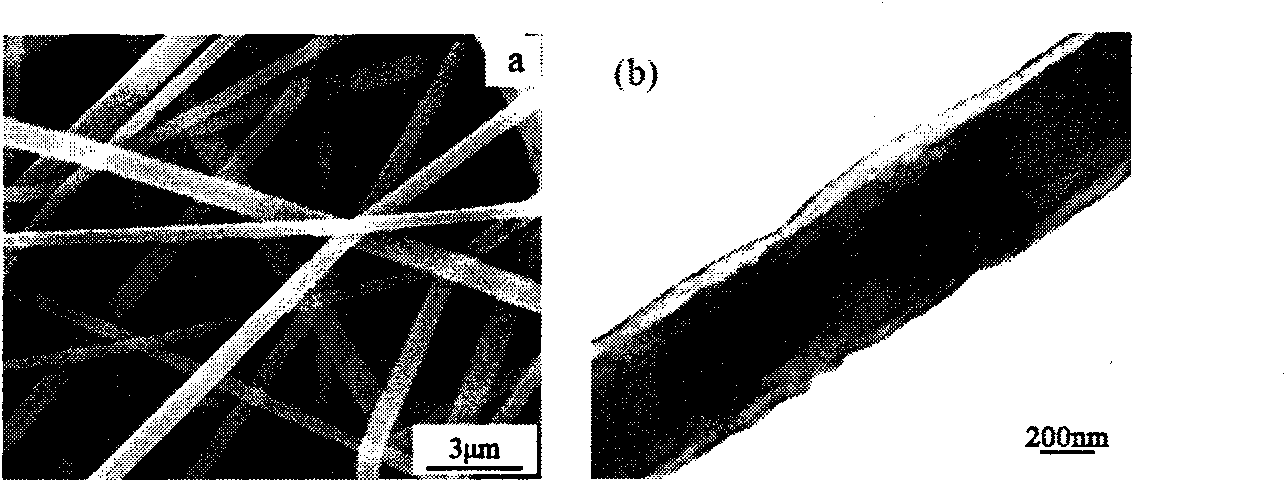

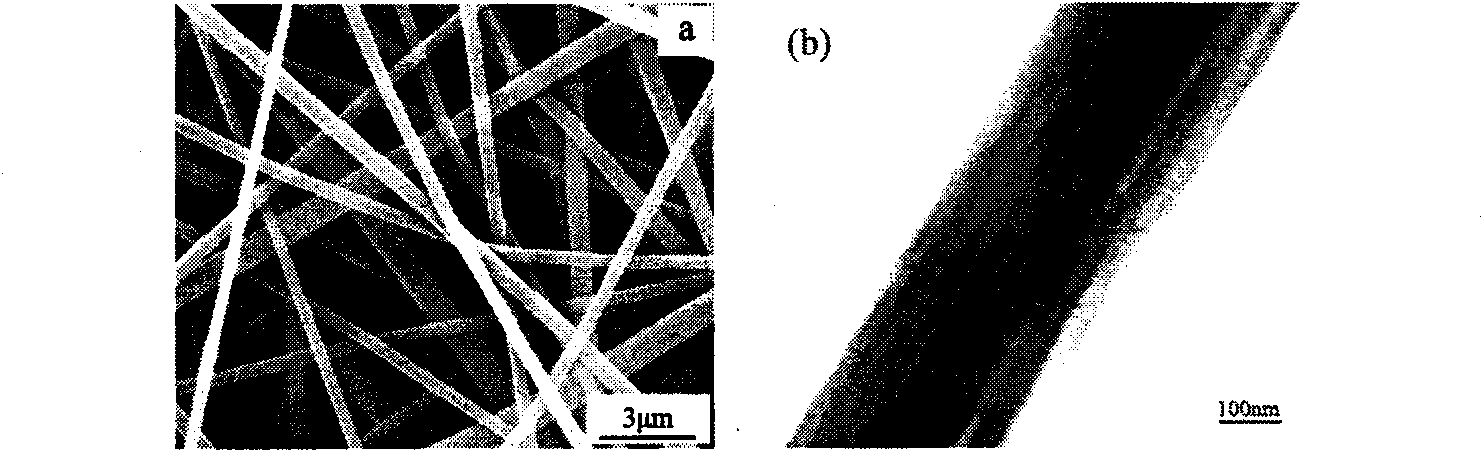

[0020] Take 0.54g of PC with a relative molecular mass of 31,000, dissolve it in a mixture of 3mL DMF and 1mL THF under magnetic stirring, and stir until it completely dissolves into a transparent solution. Add 0.18 g of PMMA with a relative molecular mass of 35,000 to it and continue stirring at 30-45° C. until uniform to obtain a transparent mixed solution. Another 1.26 g of PVDF with a relative molecular mass of 310,000 to 350,000 was added to 6 mL of DMF, and fully stirred at 30 to 45 ° C until completely dissolved into a transparent solution. The obtained PC mixed solution was added dropwise into the PVDF solution, and the stirring was continued for 1 h to obtain PMMA-containing PVDF / PC electrospinning solution for electrospinning. The syringe is secured to the microinjection pump, and a grounded metal drum receiver is placed 18 cm from the needle. Inject the above electrospinning solution into a 50mL syringe with a length of 3cm and a flat needle with an inner diameter ...

Embodiment 2

[0024]Take 0.54g of PC with a relative molecular mass of 31,000, dissolve it in a mixture of 3mL DMF and 1mL THF under magnetic stirring, and stir until it completely dissolves into a transparent solution. Add 0.09 g of PMMA with a relative molecular mass of 15,000 to it and continue to stir well at 30-45° C. until uniform to obtain a transparent mixed solution. Another 1.26 g of PVDF with a relative molecular mass of 310,000 to 350,000 was added to 6 mL of DMF, and fully stirred at 30 to 45 ° C until completely dissolved into a transparent solution. The obtained PC mixed solution was added dropwise into the PVDF solution, and the stirring was continued for 1 h to obtain PMMA-containing PVDF / PC electrospinning solution for electrospinning. The syringe is secured to the microinjection pump, and a grounded metal drum receiver is placed 18 cm from the needle. Inject the above electrospinning solution into a 50mL syringe with a length of 3cm and a flat needle with an inner diamet...

Embodiment 3

[0026] Take 0.54g of PC with a relative molecular mass of 31,000, dissolve it in a mixture of 3mL DMF and 1mL THF under magnetic stirring, and stir until it completely dissolves into a transparent solution. Add 0.27g of PMMA with a relative molecular weight of 35,000 to it and continue to stir well at 30-45°C until uniform to obtain a transparent mixed solution. Another 1.26 g of PVDF with a relative molecular mass of 310,000 to 350,000 was added to 6 mL of DMF, and fully stirred at 30 to 45 ° C until completely dissolved into a transparent solution. The obtained PC mixed solution was added dropwise into the PVDF solution, and the stirring was continued for 1 h to obtain PMMA-containing PVDF / PC electrospinning solution for electrospinning. The syringe is secured to the microinjection pump, and a grounded metal drum receiver is placed 18 cm from the needle. Inject the above electrospinning solution into a 50mL syringe with a length of 3cm and a flat needle with an inner diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com