Cold precision forming technique of helical-spur gear and device thereof

A helical cylindrical gear, precision forming technology, applied in the direction of belt/chain/gear, gear teeth, components with teeth, etc., can solve the problems of complex helical gear tooth profile, difficult tooth profile, high forming stress of spur gear, Achieve high production efficiency, reduce final forming pressure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

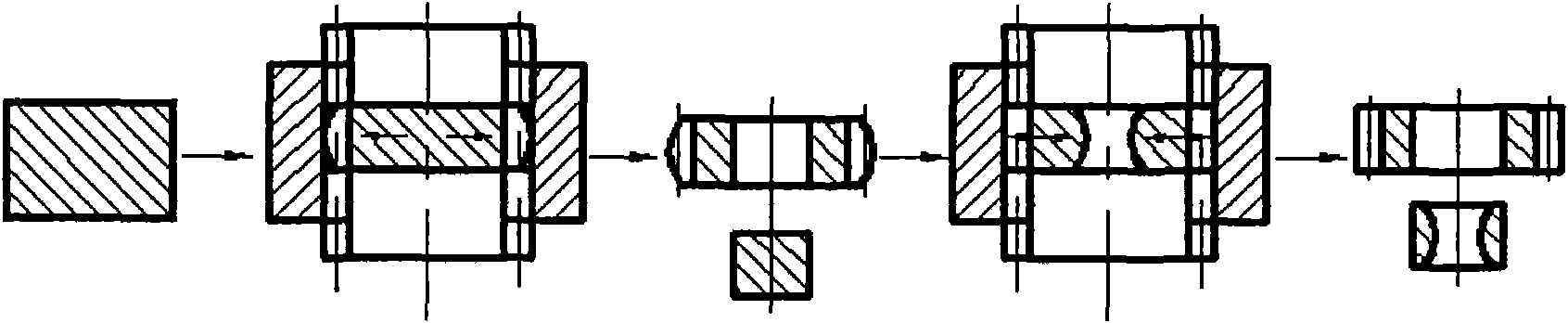

[0028] The present invention is described below in conjunction with accompanying drawing structure, action as follows:

[0029] Such as Image 6 As shown: the blank 1 is put into the die 7, and the press moves downward. When the upper and lower pressing plates 11 and 8 are in contact (because the die 7 is fixed on the lower pressing plate 8), the upper and lower outer oil cylinders 13 and 3 start to discharge oil outwards. Because the die is fixed on the lower pressing plate, the die 7 starts to float downwards this moment. The upper and lower inner and outer punches 9 and 5 contact the blank 1, and start to carry out two-way extrusion on the blank 1. After a certain depth is squeezed, the oil pressure in the upper and lower inner oil cylinders 12 and 2 rises to the set oil pressure, and the upper and lower inner oil cylinders 12 and 2 Start to drain oil through the oil pipe, and now the upper and lower inner punches stop squeezing in or retreating, while the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com