Gear lubricating device for ball mill

A lubricating device and ball mill technology, applied in grain processing and other directions, can solve the problems of insufficient lubrication, easy dust pollution, waste of external dust, etc., and achieve the effects of advanced design, good lubrication effect and uniform oil injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

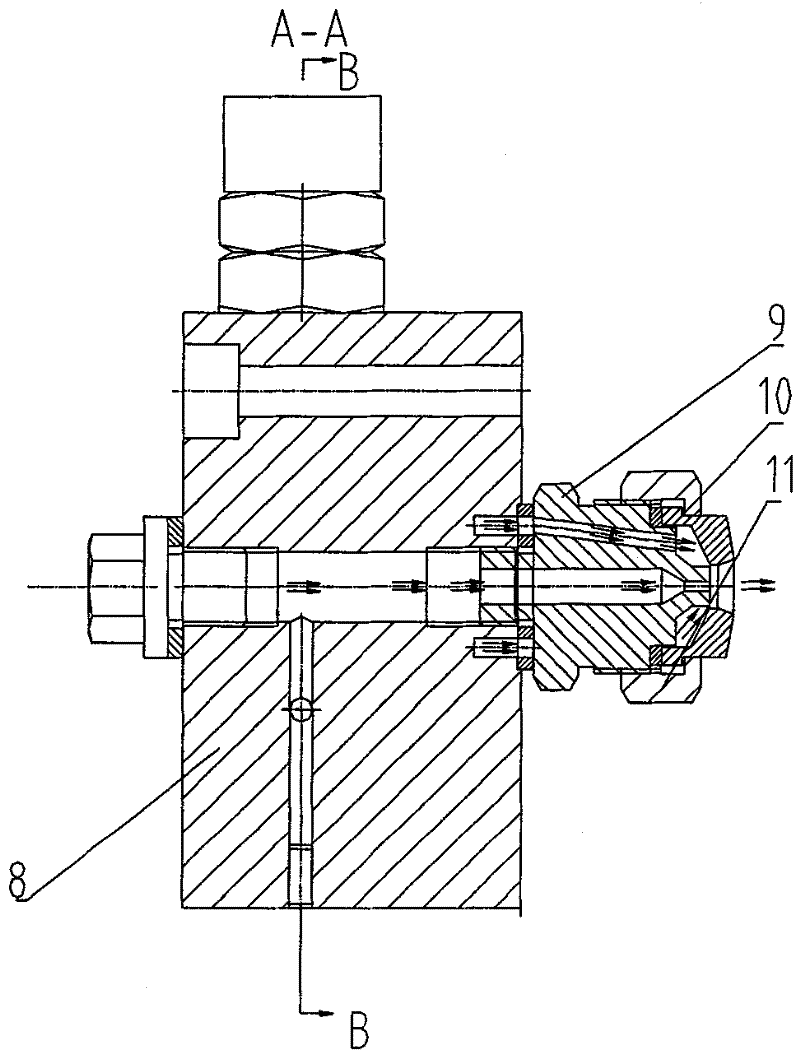

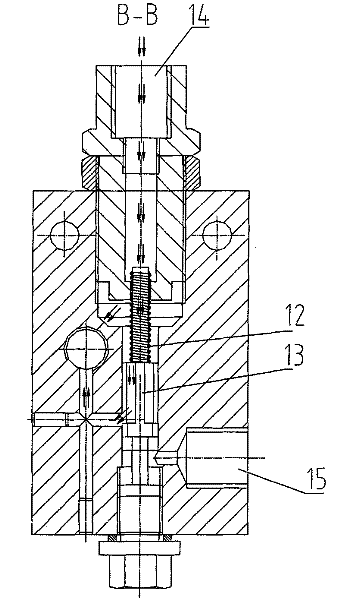

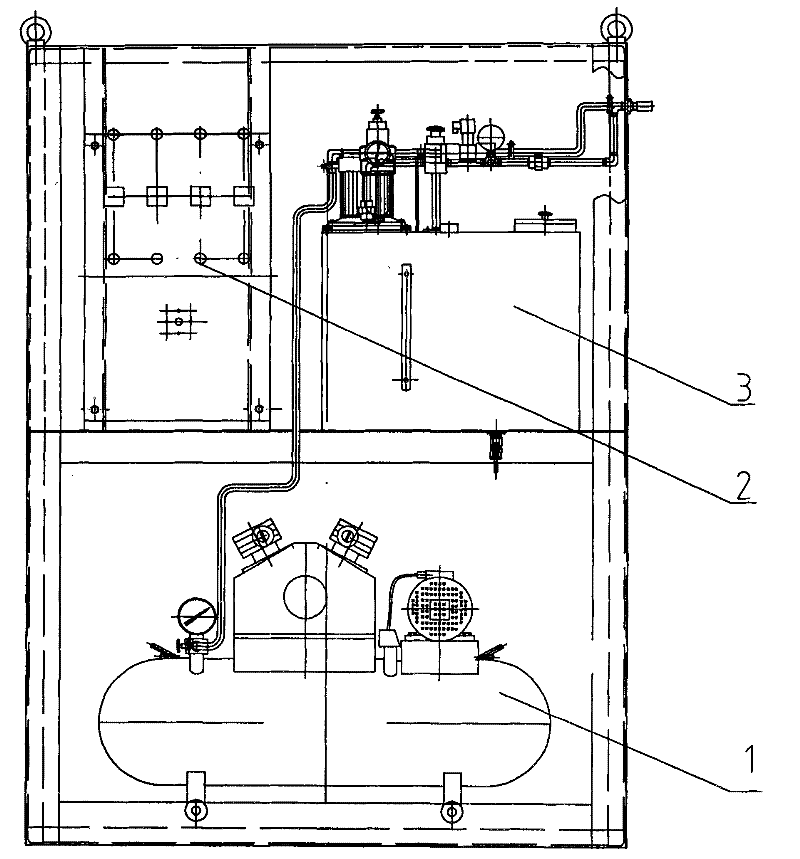

[0020] figure 1 middle, figure 2 , image 3 Among them, it includes a pneumatic system 1 and a hydraulic system 3, both of which are connected to the control system 2, and the pneumatic system 1 includes an air pump, a water separation filter, a solenoid valve, and is connected to the injection plate device 5 through a pipeline 4. The hydraulic system 3 includes a fuel injection pump, a one-way valve, and a pressure regulating valve, and is connected to the injection plate device 5 through a pipeline 4 . The electrical control system 2 is a single-chip microcomputer, which controls the fuel injection pump and the air pump respectively.

[0021] At the same time, the air pressure system 1 and the hydraulic system 3 are respectively connected to the spray plate device 5 through the pipeline 4, and the spray plate device 5 is installed on the gear cover 6 at a position matched with the gear meshing part. The injection plate device 5 is provided with a nozzle 7, the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com