Catalyst for olefin catalytic cracking to produce propylene and ethylene and application thereof

A catalytic cracking and catalyst technology, applied in the field of ethylene catalyst, catalytic cracking to produce propylene, can solve the problem of not being able to operate for a long time, and achieve the effects of small grain size, high acid density and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of H-type ZSM-5 molecular sieve:

[0058] After the ZSM-5 molecular sieve raw powder with the required silicon-aluminum ratio and particle size was roasted at 550°C to remove the template agent, the ratio of molecular sieve (g) to exchange solution (ml) was 1:10, and NH 4 NO 3 The solution (0.8mol / L) was exchanged in a 90°C water bath for 5 hours, and filtered; the filter cake was exchanged twice with the same amount of exchange liquid as before, filtered, and washed with distilled water until there was no NO in the filtrate. 3 - Existence, drying at 110°C, and calcining at 550°C to obtain HZSM-5 molecular sieve.

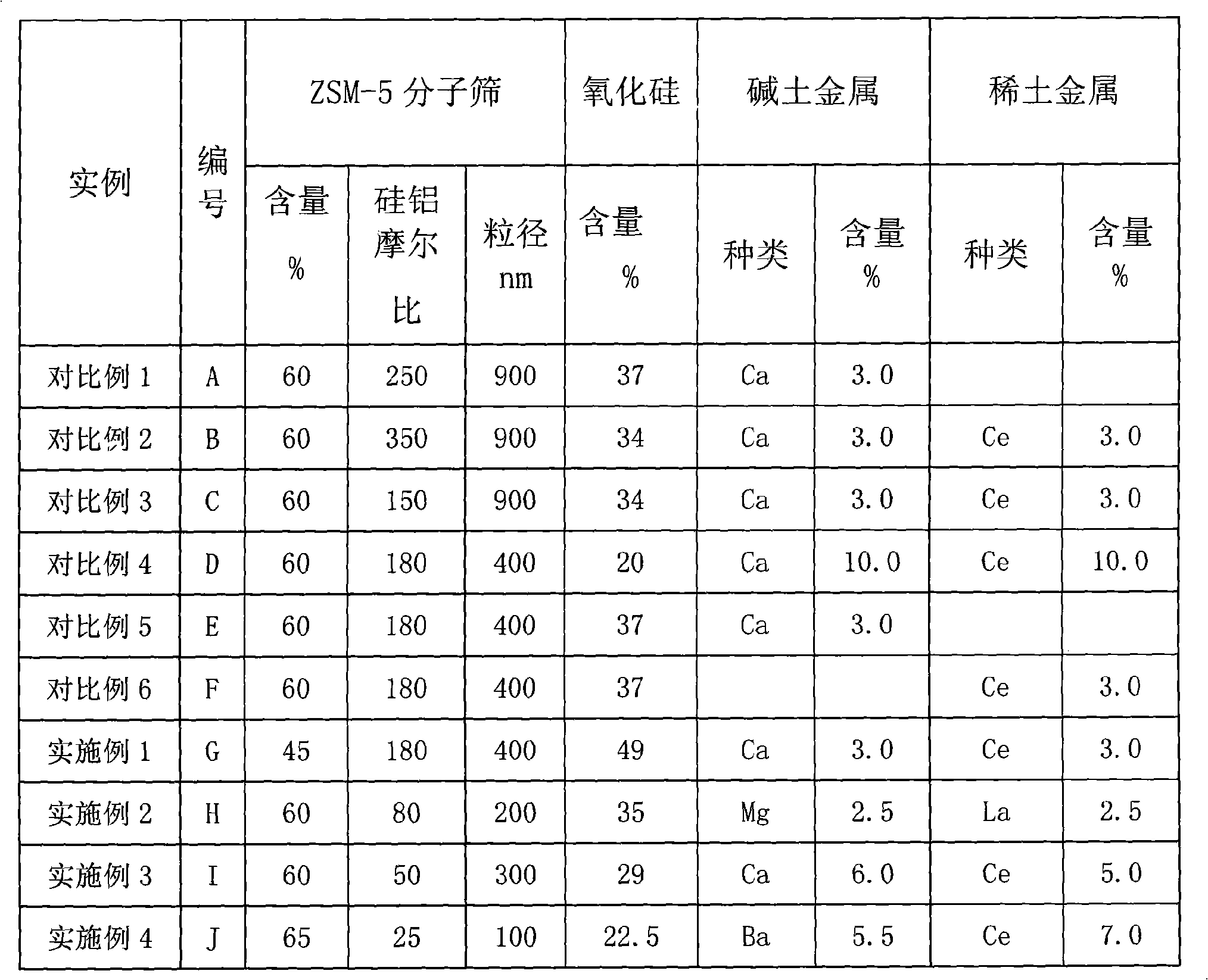

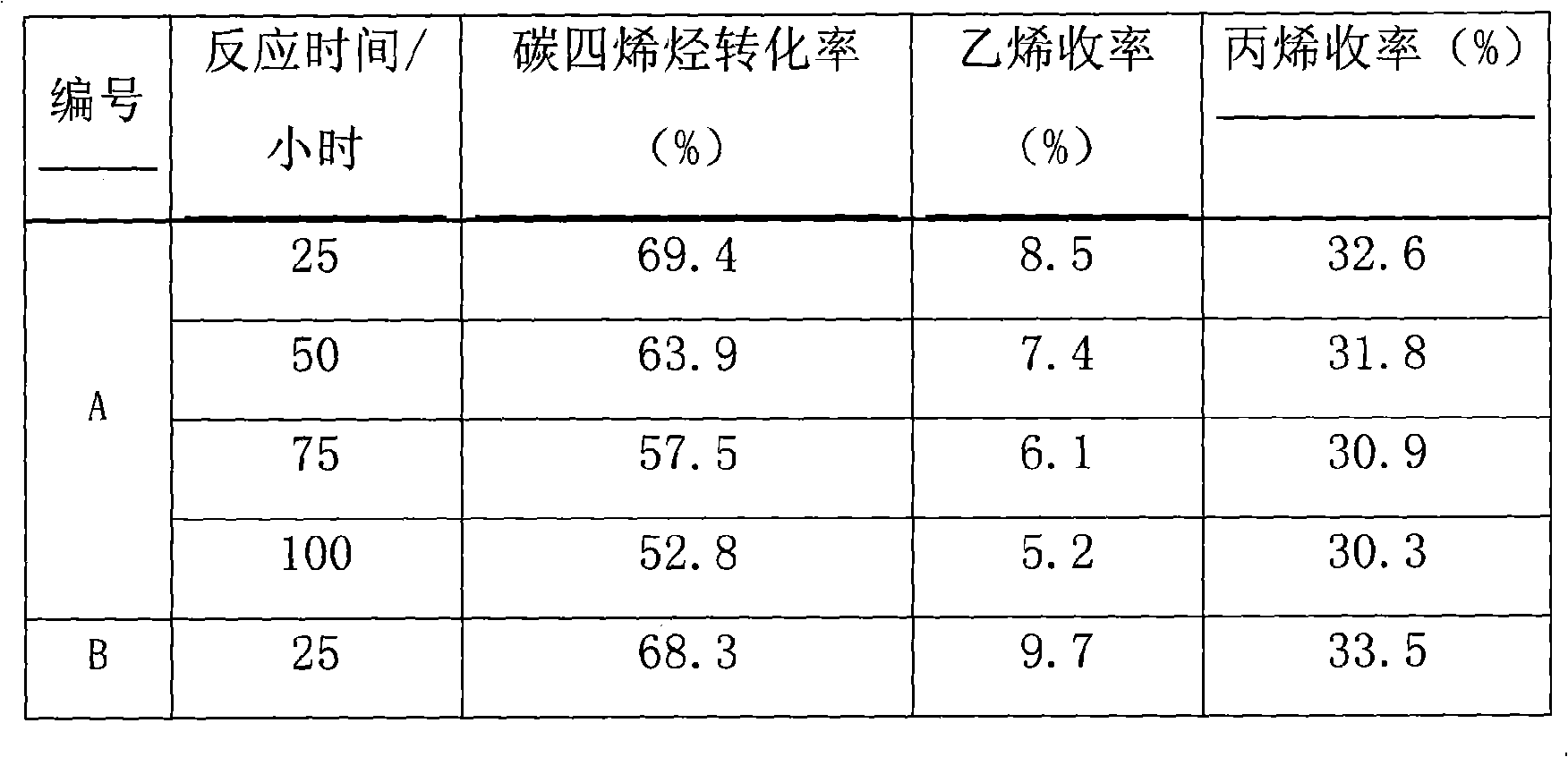

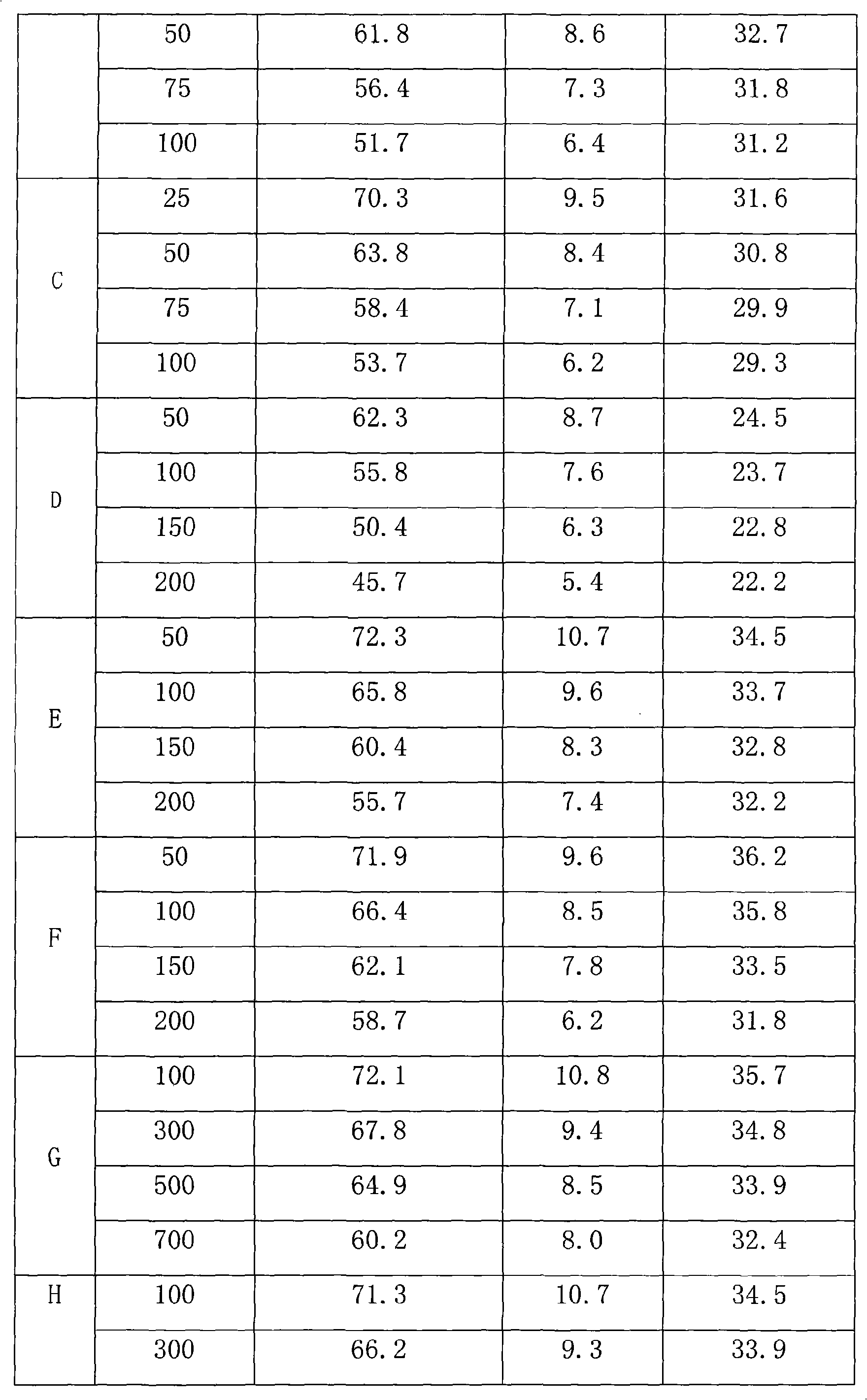

Embodiment 1

[0072] The raw powder of ZSM-5 molecular sieve (mole ratio of silicon to aluminum is 180, particle size is 400nm) is processed according to the above preparation method to obtain HZSM-5 molecular sieve. The HZSM-5 molecular sieve and silicon oxide (specific surface area > 200M 2 / g of high-purity silica) and squat powder are mixed in proportion, after mixing, add an appropriate amount of dilute nitric acid, after mixing, extrude into a cylindrical shape with a diameter of 3mm, dry at 120°C and roast at 550°C to obtain a molecular sieve containing ZSM-5 and silicon oxide strips. Take a certain amount of cylindrical particles, and use Ca(NO 3 ) 2 and Ce(NO 3 ) 3 The solution impregnated the particles, filtered and separated, dried at 120°C and calcined at 550°C, impregnated with Ca and Ce, treated with water vapor at 500°C for 5 hours, and treated with 0.2mol / L citric acid solution in a 90°C water bath for 3h , after solid-liquid separation and calcined at 600°C for 4 hours...

Embodiment 2

[0074] Treat the original powder of ZSM-5 molecular sieve (silicon-aluminum molar ratio is 80, particle size is 200nm) according to the above preparation method: change the roasting temperature of molecular sieve raw powder from 550°C to 450°C, change the exchange time from 5h to 3h, after exchange The roasting temperature of the filter cake was changed to 650°C, and other conditions remained unchanged to obtain HZSM-5 molecular sieve. The HZSM-5 molecular sieve and silicon oxide (specific surface area > 200M 2 / g of high-purity silica) and squat powder are mixed in proportion, after mixing, add an appropriate amount of dilute nitric acid, after mixing, extrude into a cylindrical shape with a diameter of 3mm, dry at 120°C and roast at 550°C to obtain a molecular sieve containing ZSM-5 and silicon oxide strips. Take a certain amount of cylindrical particles, at room temperature with Mg(NO 3 ) 2 and La(NO 3 ) 3 The solution impregnated the particles, filtered and separated,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com