Method for preparing submicron-sized anode material LiCoxNiyMnzO2 of lithium-ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems that greatly affect material rate charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

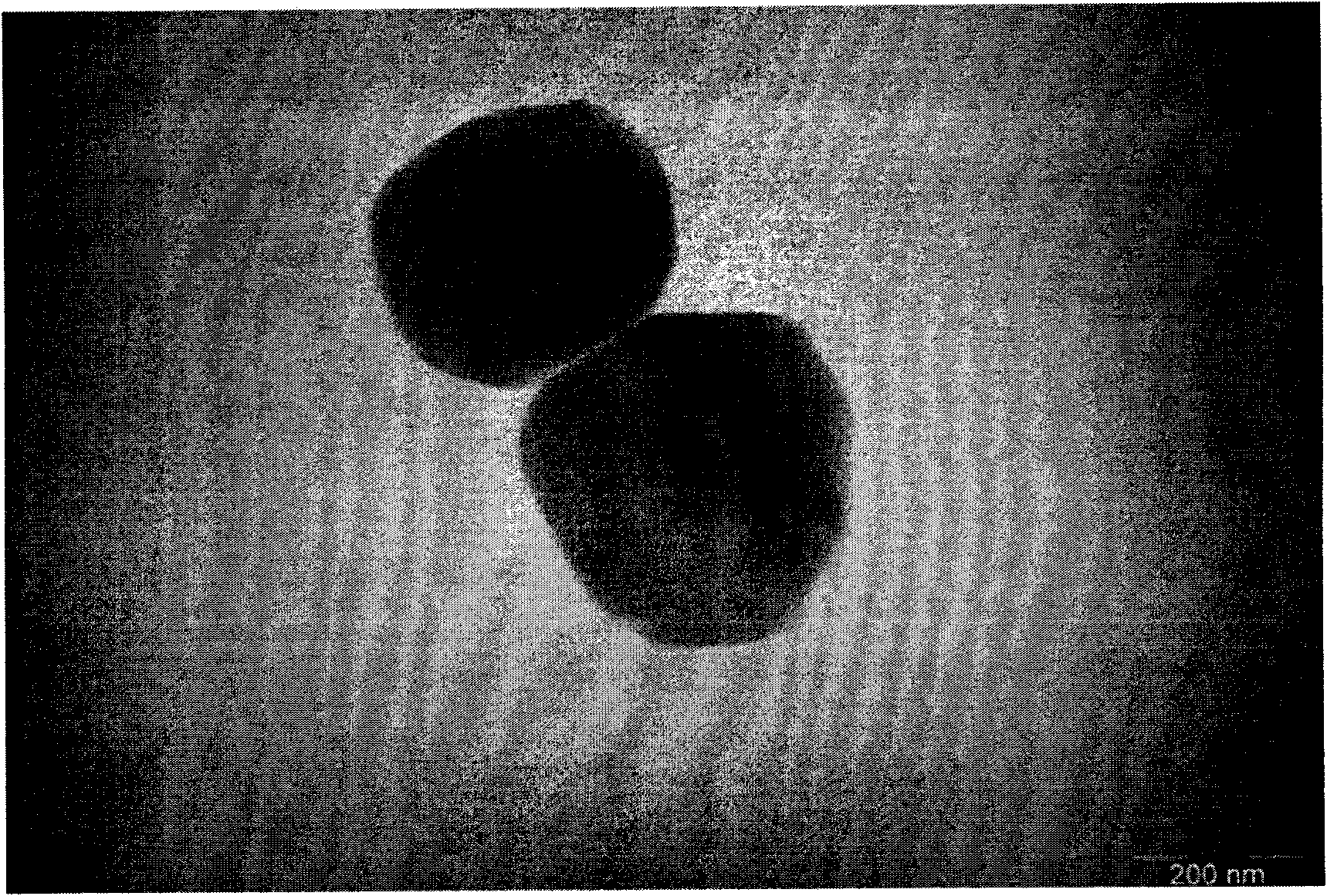

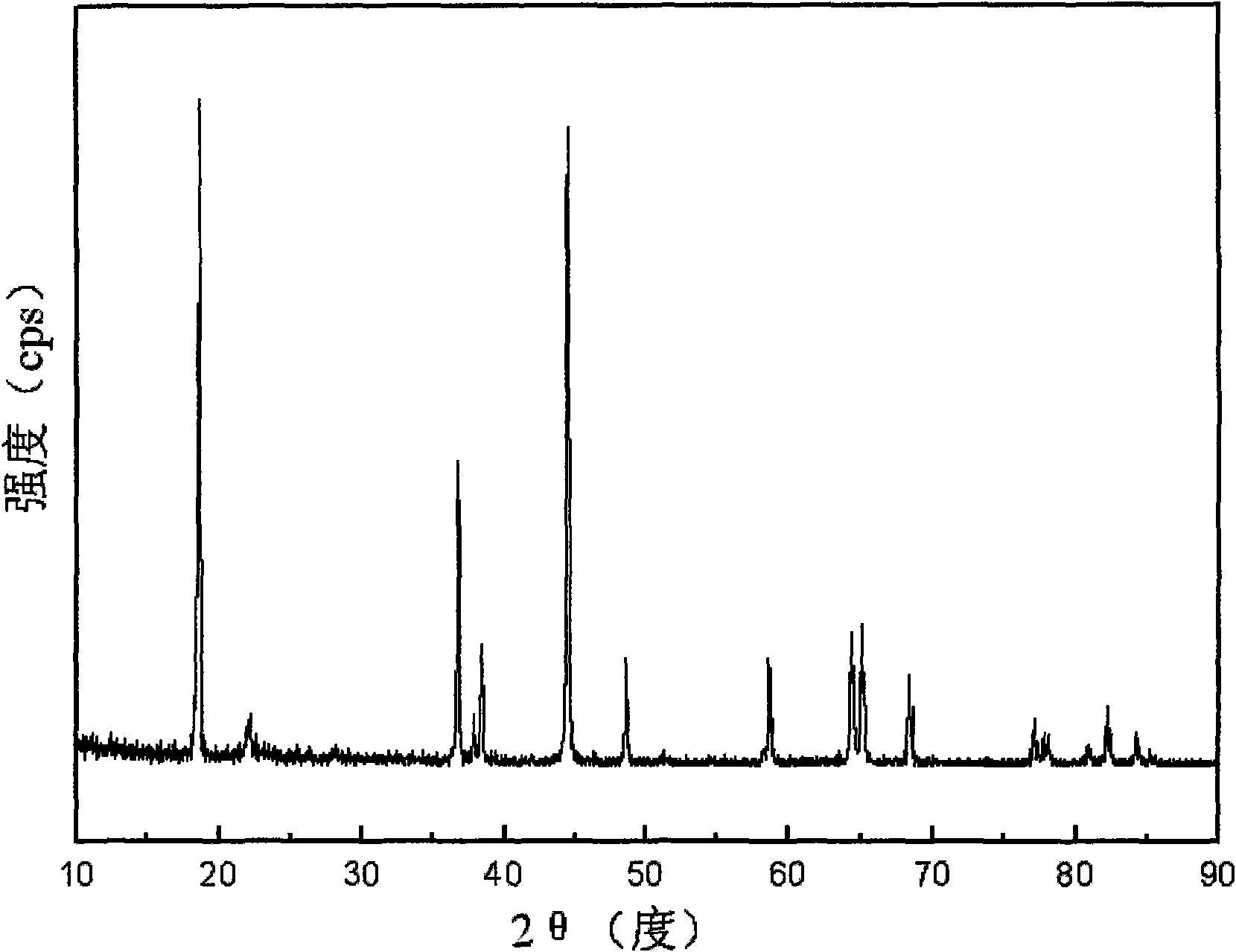

[0009] Specific implementation mode 1: In this implementation mode, the positive electrode material LiCo of sub-micron lithium-ion battery x Ni y mn z o 2 The preparation method is as follows: 1. According to the chemical formula LiCo x Ni y mn z o 2 , respectively weigh cobalt salt, nickel salt and manganese salt according to the molar ratio of Li element, Ni element and Mn element as x:y:z, and then dissolve them in distilled water to obtain system 1, where x Ni y mn z o 2 ; Wherein the concentration of cobalt salt in step 1 system 1 is 0.5~2mol / L; In step 3, the volume ratio of system 1 and system 2 is 1: 1, and the volume ratio of distilled water and system 1 is 2.5~10: 1, step 3 The reaction vessel described in was placed in a mixture of ice and water.

[0010] The ball mill used in this embodiment is a QM-3SP04 planetary ball mill produced by Nanjing University Instrument Factory.

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that the cobalt salt described in step 1 is cobalt sulfate, cobalt acetate or cobalt nitrate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the cobalt salt described in step 1 is a combination of any two of cobalt sulfate, cobalt acetate and cobalt nitrate. Others are the same as in the first embodiment.

[0013] In the cobalt salt described in this embodiment, the two components are mixed in any ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com