Anode composite material of lithium ion battery and preparation method thereof

A lithium-ion battery and composite material technology, which is applied in the field of lithium-ion battery positive electrode composite materials and its preparation, can solve the problems of complex process, difficult control, material containing impurity phase, uneven distribution, etc., and achieve enhanced solid-state ion diffusion ability and improved Reactivity, the effect of accelerating the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

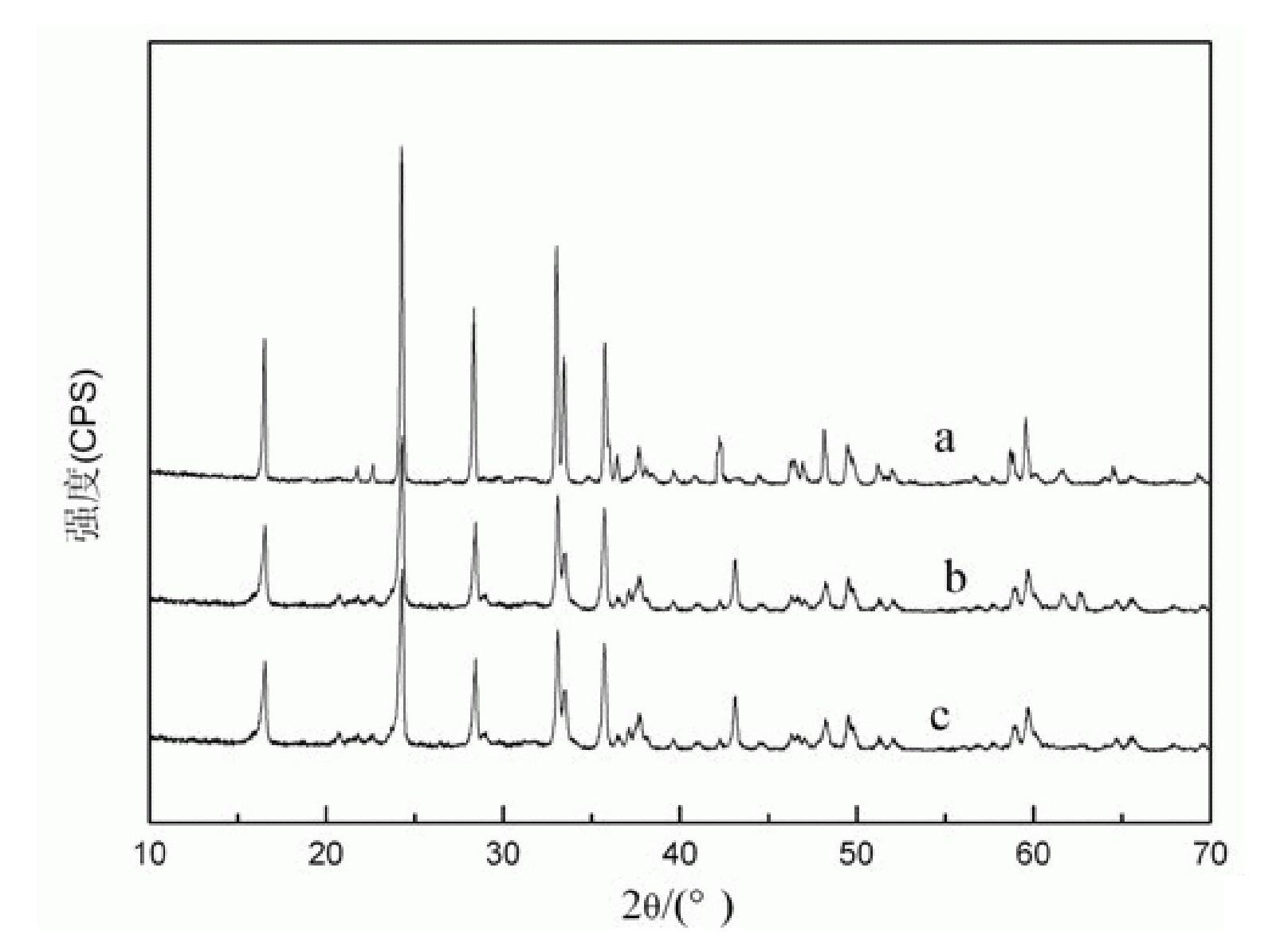

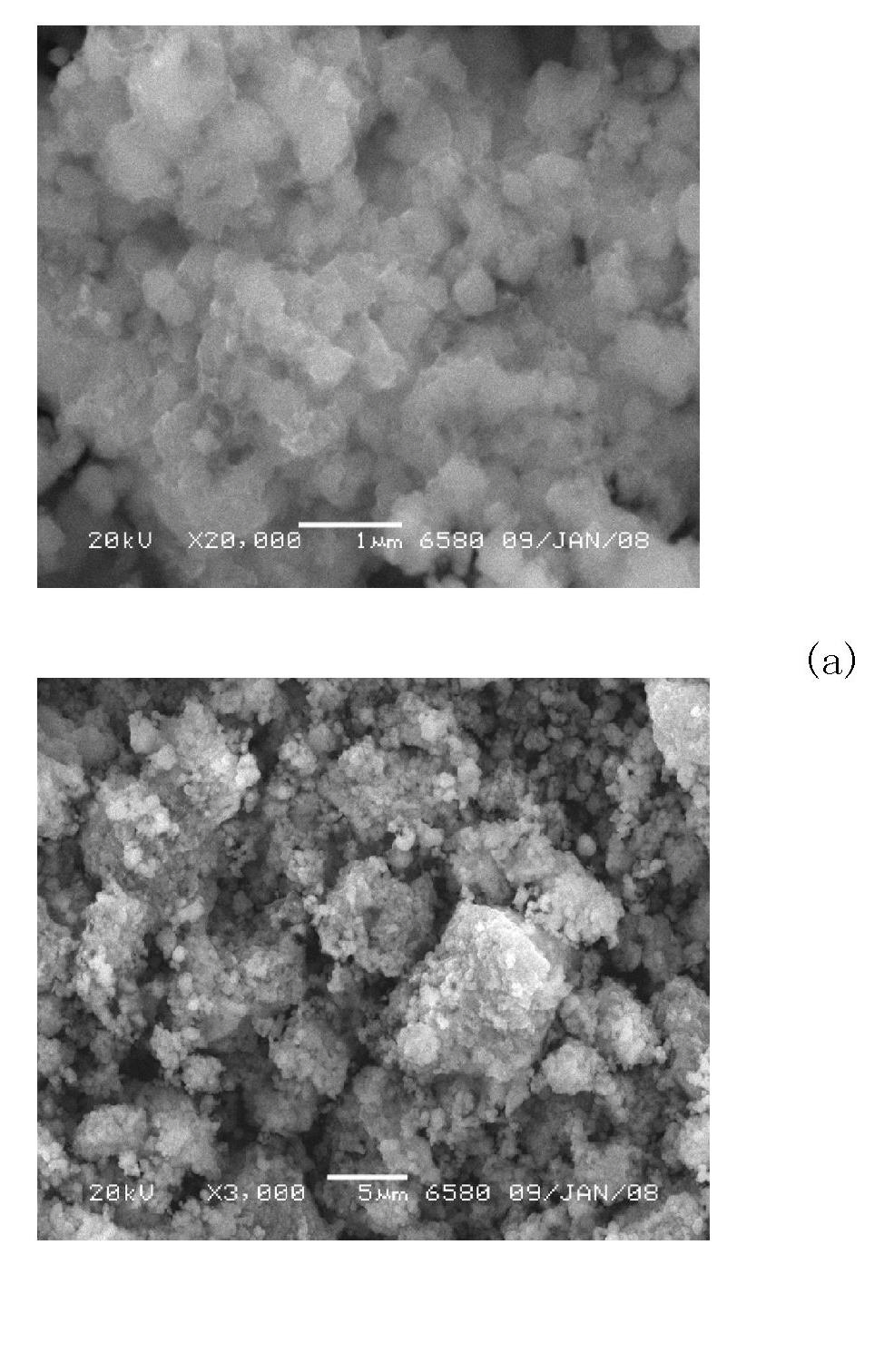

Embodiment 1

[0024] 19.88gFeCl 2 ? 4H 2O and 28.42 g Na 2 SiO 3 9H 2 O ball mill and mix evenly for 60 min, wash the above mixture three times with deionized water, filter, and dry at 80°C. Will obtain precursor powder again with 7.4g Li 2 CO 3 Ball mill with 5.5 g of starch for 5 hours, mix evenly, press into tablets, and heat at 750° C. for 8 minutes in a microwave under the protection of argon to obtain the composite material. In this composite, 95% w Li 2 FeSiO 4 , 5% w C. No Fe was seen in the XRD pattern 2 o 3 , SiO 2 , Li 2 SiO 3 The composite material has high phase purity and good crystallization performance. The composite positive electrode material has a current density of 10mAg -1 Under the same conditions, the specific capacities of the first two discharges are 109.9 and 110mAh·g respectively -1 .

Embodiment 2

[0026] 9.94gFeCl 2 4H 2 O and 8.62g K 2 SiO 3 ·H 2 O ball mill and mix evenly for 40 min, wash the above mixture three times with deionized water, filter, and dry at 60°C. The obtained precursor powder was mixed with 4.42g LiOH·H 2 O and 6g of glucose were ball-milled for 4 hours, mixed uniformly, pressed into tablets, and heated at 650° C. for 10 minutes under the protection of argon by microwave to obtain the composite material. In this composite, 90% w Li 2 FeSiO 4 , 10% w C. The composite cathode material at 10mAg -1 and 30mAg -1 Under the condition of current density, the first discharge specific capacity is 119.6, 103.7mAh g -1 .

Embodiment 3

[0028] 6.95gFeSO 4 ·7H 2 O and 7.11 g Na 2 SiO 3 9H 2 O ball mill and mix evenly for 30 min, wash the above mixture three times with deionized water, filter, and dry at 70°C. The obtained precursor powder was mixed with 5.1g LiAc·2H 2 O and 4.5 g of sucrose were ball milled for 3 hours, mixed evenly, pressed into tablets, and heated at 600° C. for 15 minutes by microwave under the protection of argon to obtain the composite material. In this composite, 85% w Li 2 FeSiO 4 , 15% w C. No Fe was seen in the XRD pattern 3 o 4 , SiO 2 , Li 2 SiO 3 Other heterogeneous phases exist, and the composite material has a higher phase purity. The composite cathode material at 10mAg -1 Under current density conditions, the specific capacities of the second and third discharges are 120.9 and 121.7mAh g respectively -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com