Charging method for pre-baking aluminum electrolytic tank

An aluminum electrolytic cell and furnace loading technology, which is applied in the field of furnace loading when the electrolytic cell is started, can solve the problems of long recovery period, fusion, and increase the start-up cost of the electrolytic cell, and achieve the effect of shortening the recovery period and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Furnace loading process before wet start-up of 160KA electrolyzer after overhaul

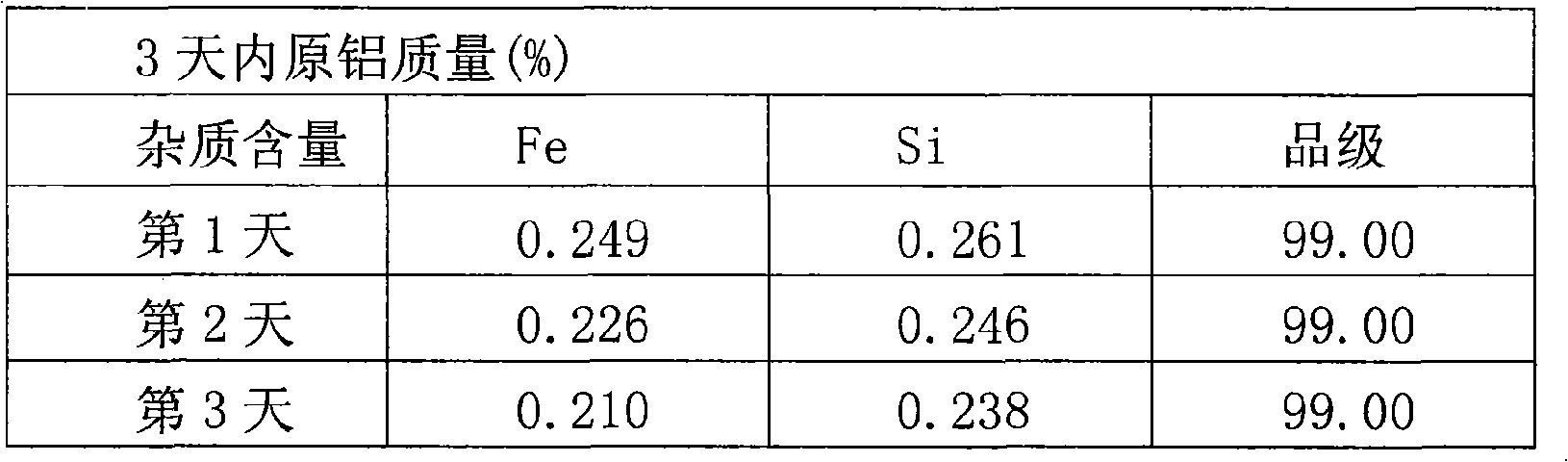

[0022] First, weigh 450 kg of calcined petroleum coke grains and pour them on the coke grain bed, divide them into three grades of 0.5 mm, 1.2 mm and 2.3 mm according to the particle size, preheat to 220°C, and then adjust the weight ratio to 50:27:23 The ratio is uniformly mixed, so that the calcined petroleum coke particles are evenly laid on the graphite cathode. Install the anode to ensure that the bottom palm of the anode is in full contact with the coke particles. Lay 0.6t of calcium fluoride on the side artificial legs. Electrolyte blocks with a molecular ratio of 2.6 are used for the gaps and middle gaps between the anodes. Electrolyte blocks with a particle size of 40-45 mm and 220-250 mm are selected as coverings according to the gap width, and then newspapers are used to cover the electrolyte blocks; The mixture of cryolite and soda ash with a ratio of 0.8:1 is 3 tons. The a...

Embodiment 2

[0025] Furnace loading process before wet start-up of 150KA electrolyzer after overhaul.

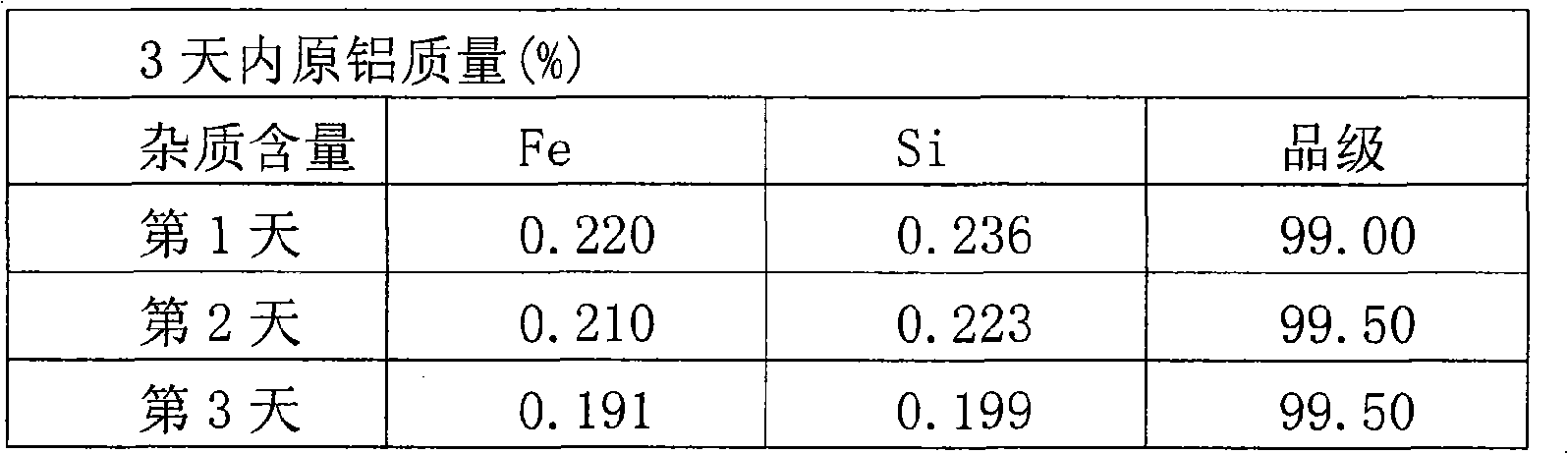

[0026] First weigh 420-430 kg of calcined petroleum coke particles and pour them on the sieve plate, divide them into three grades of 0.5 mm, 2 mm and 3 mm according to the particle size, preheat to 250 °C, and then adjust the weight ratio to 50:27 The ratio of : 23 is evenly mixed, so that the calcined petroleum coke particles are evenly laid on the graphite cathode. Install the anode to ensure that the bottom palm of the anode is in full contact with the coke particles. Lay 0.6 tons of calcium fluoride on the side artificial leg. Electrolyte blocks with a molecular ratio of 2.8 are used for the gaps and middle gaps in the anode, and electrolyte blocks with a particle size of 45-50 mm and 225-270 mm are selected as sealants according to the gap width, and then newspapers are used to cover the electrolyte block; 2.8 cryolite covering, sealing thickness 20cm. The quality of primary alu...

Embodiment 3

[0029] Furnace loading process before wet start-up of 300KA electrolyzer after overhaul.

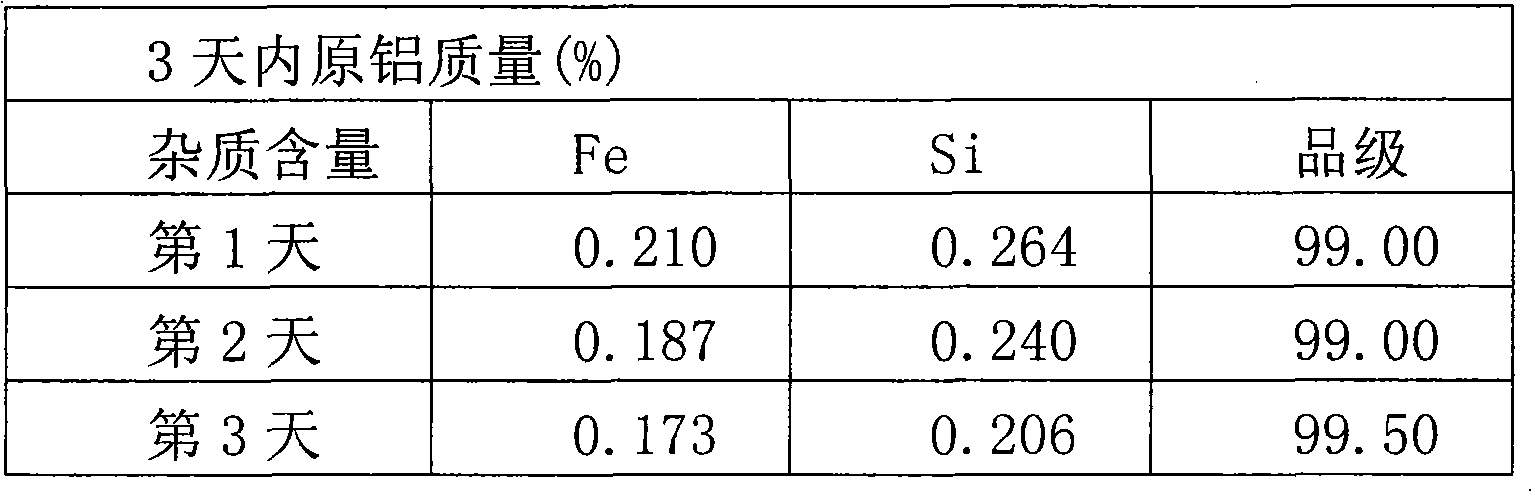

[0030] First, weigh 700 kg of calcined petroleum coke particles and pour them on the sieve plate, divide them into three grades of 1 mm, 2 mm and 4 mm according to the particle size, preheat to 250 °C, and then adjust the weight ratio to 50:27:23 The ratio is uniformly mixed, so that the calcined petroleum coke particles are evenly laid on the graphite cathode. Install the anode to ensure that the bottom palm of the anode is in full contact with the coke particles. Lay 1.2 tons of calcium fluoride on the side artificial legs. Electrolyte blocks with a molecular ratio of 3.0 are used for the gaps and middle gaps between the anodes. Electrolyte blocks with a particle size of 50-70 mm and 280-300 mm are selected as sealants according to the gap width, and then newspapers are used to cover the electrolyte blocks; 3.0 cryolite covering, sealing thickness 18cm. The quality of primary alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com