Low-frequency high dielectric reactance reduction ceramic material and preparation method thereof

A technology of high dielectric and ceramic materials, applied in the direction of ceramics and inorganic insulators, etc., can solve the problems of large-capacity Y5V ceramic materials with thin dielectric materials in the market, high prices, and restrictions on the development of new electronic components and their material industries. , to achieve the effect of fine grain, good uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

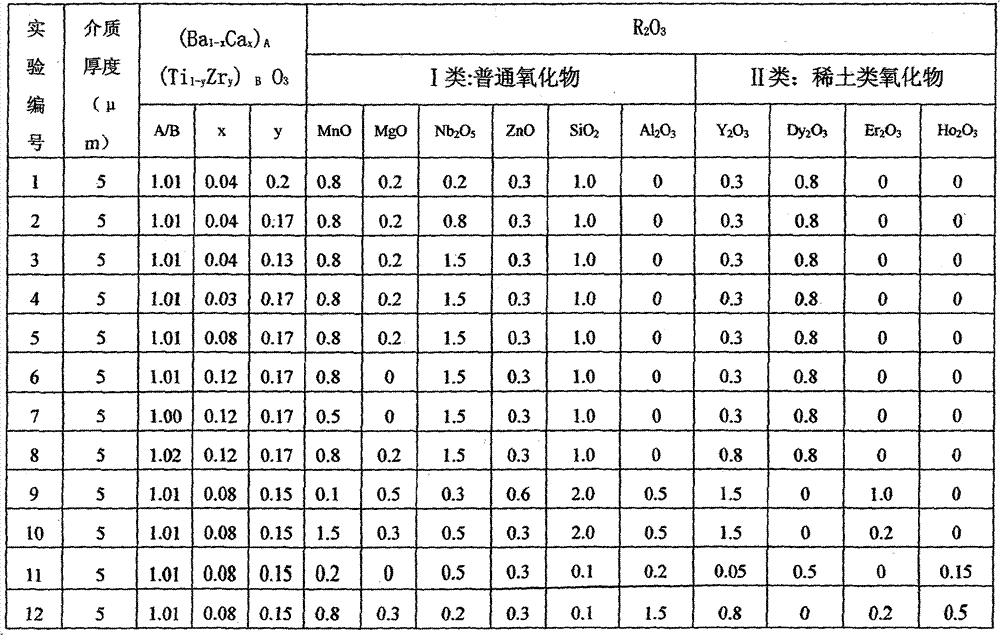

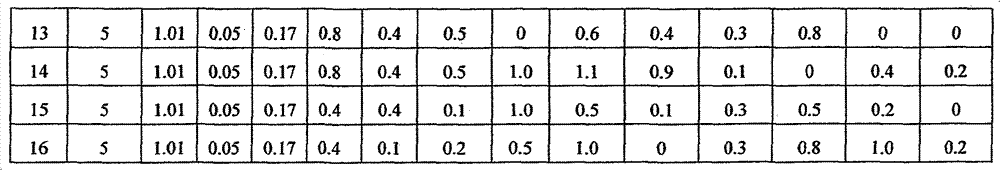

[0021] A low-frequency high-dielectric anti-reduction ceramic material, composed of a main crystal phase and a modified additive, is composed of a main crystal phase and a modified additive, and its structural formula is (1-a)(Ba 1-x Ca x ) A (Ti 1-y Zr y ) B o 3}.aR 2 o 3 , where (Ba 1-x Ca x ) A (Ti 1-y Zr y ) B o 3 The structural formula of the main crystal phase, R 2 o 3 Represents modified additives; the values of a, A / B, x, and y are shown in No. 1-16 of Table 1. During the treatment of the main crystal phase, one calcination treatment is included, and the calcination temperature is 1000-1100 ℃, and the calcination holding time is 2 to 4 hours respectively. The modified additives added are shown in formula No. 1-16 in Table 1. The mixing treatment of the main crystal phase and the modified product includes secondary calcination treatment. The calcination temperature is 1050-1200°C, and the calcination holding time is 2-4 hours. .

[0022] MLCC produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap