Railway locomotive and vehicle operating attitude measurement system

A measurement system and vehicle operation technology, applied in the direction of railway vehicle shape measuring device, railway car body parts, measuring devices, etc., can solve the problem that the running attitude cannot be monitored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

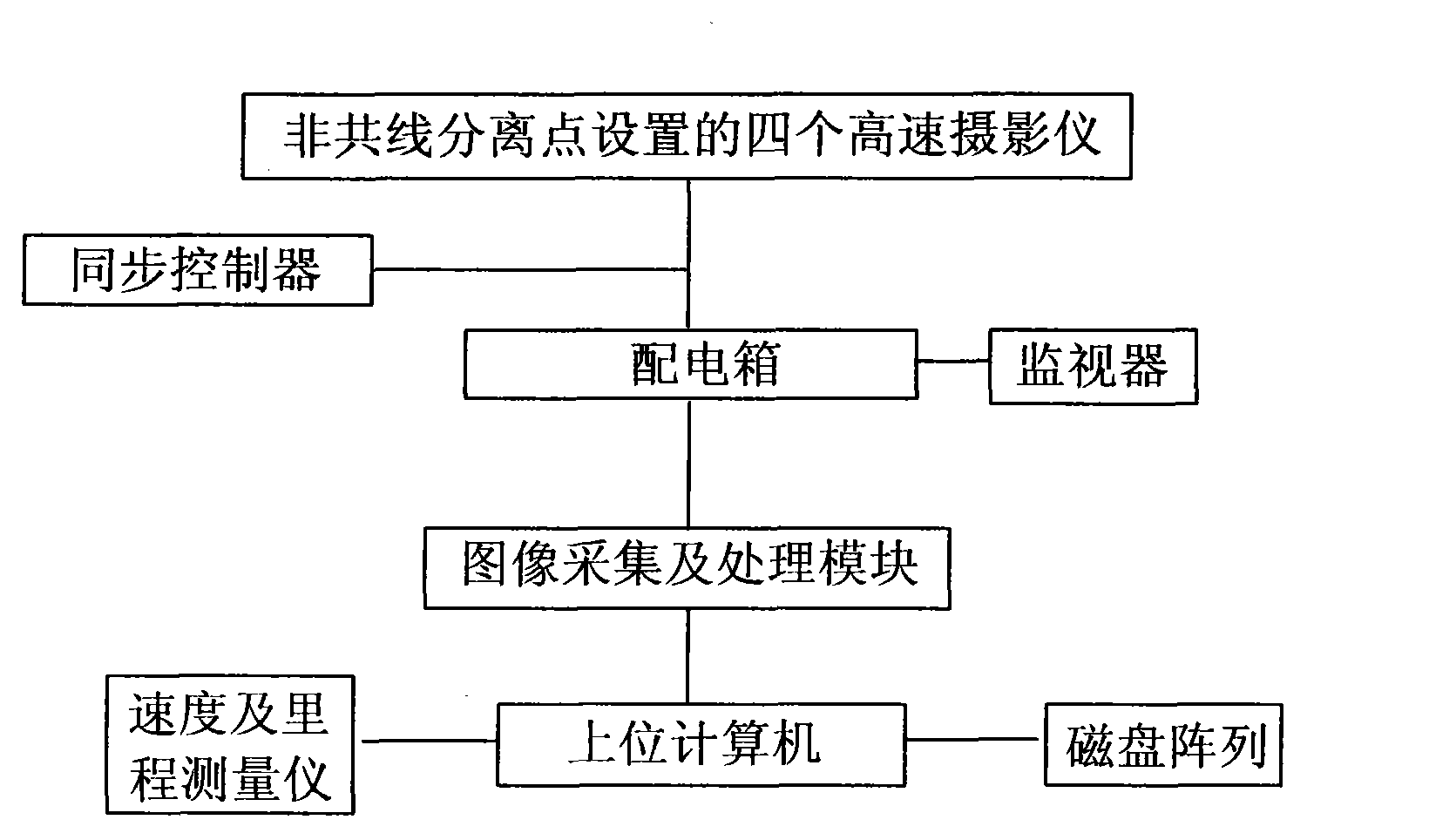

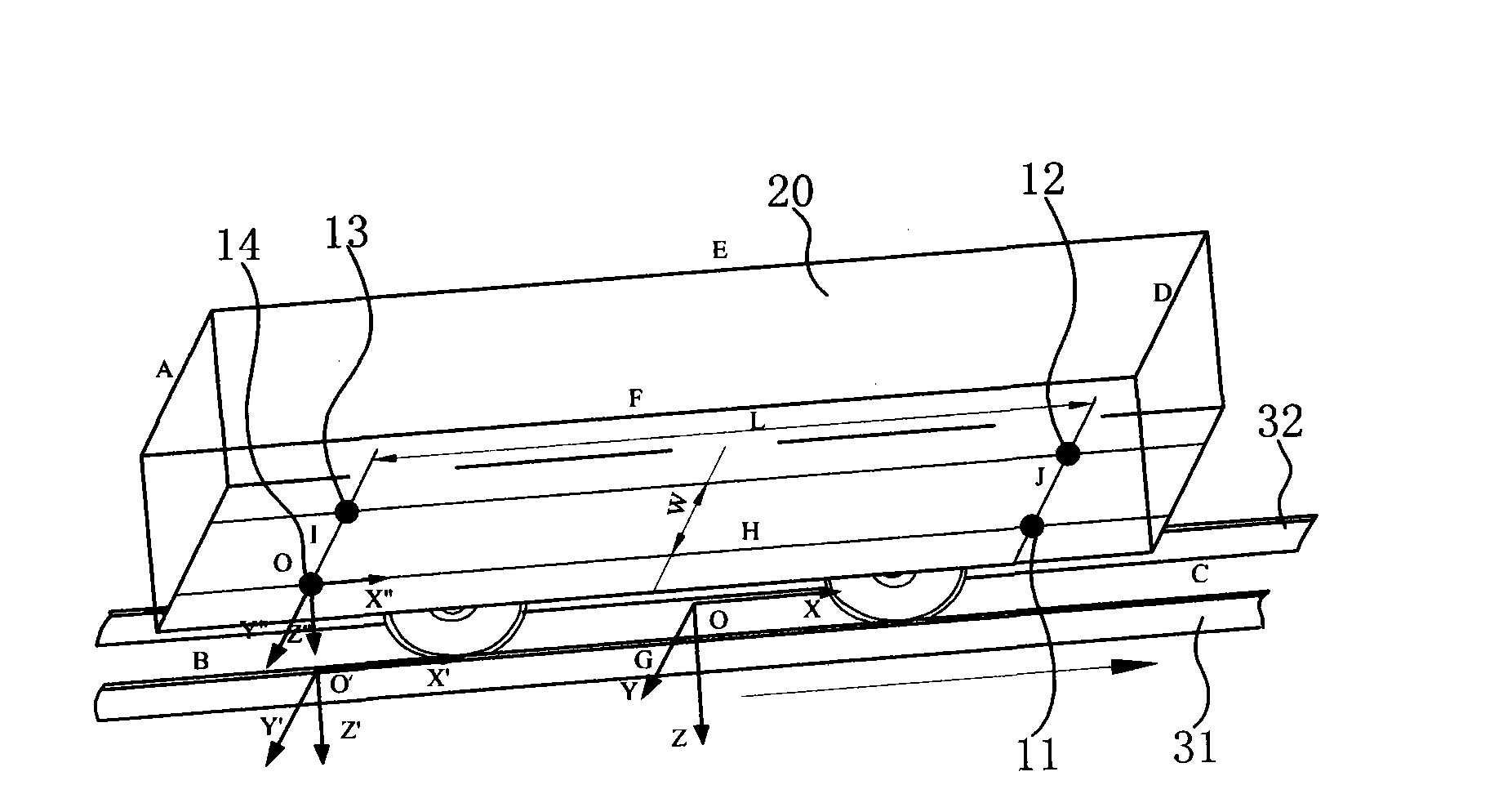

[0034] Such as figure 1 As shown, the railway rolling stock operating attitude measurement system uses a high-speed camera to obtain the image sequence of the top surface of the track when the train is running, which includes:

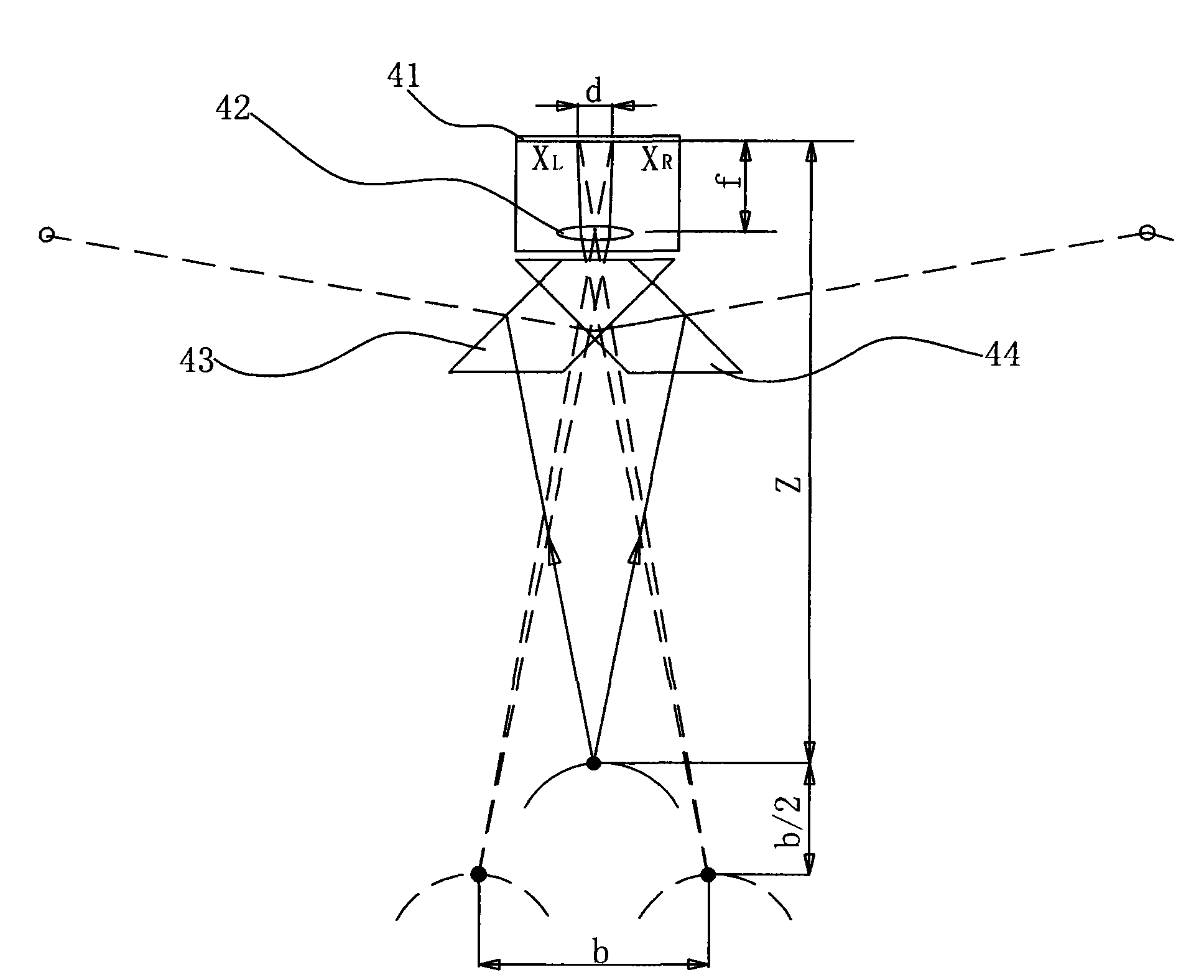

[0035] The four high-speed camera CCDs set at the non-collinear separation point, that is, the four high-speed cameras are installed in a plane different from the top surface of the vertical rail. Four high-speed cameras are set relative to the running track of the tested car body and used to capture the track image sequence when the train is running;

[0036] A synchronous controller, the synchronous controller controls the high-speed cameras installed on the four points to perform time synchronization and data acquisition synchronization.

[0037] Image acquisition and processing module, this module receives the track image sequence, and analyzes the track surface image sequence acquired by the high-speed camera at each point, obtains the offset of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com