High-speed sampling method and device for test fire smoke particle

A high-speed sampling, smoke particle technology, applied in sampling devices and other directions, can solve the problems of verification difficulties, data are not comparable, no operating procedures, etc., to achieve full flexibility, good overall performance, and promote the effect of homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

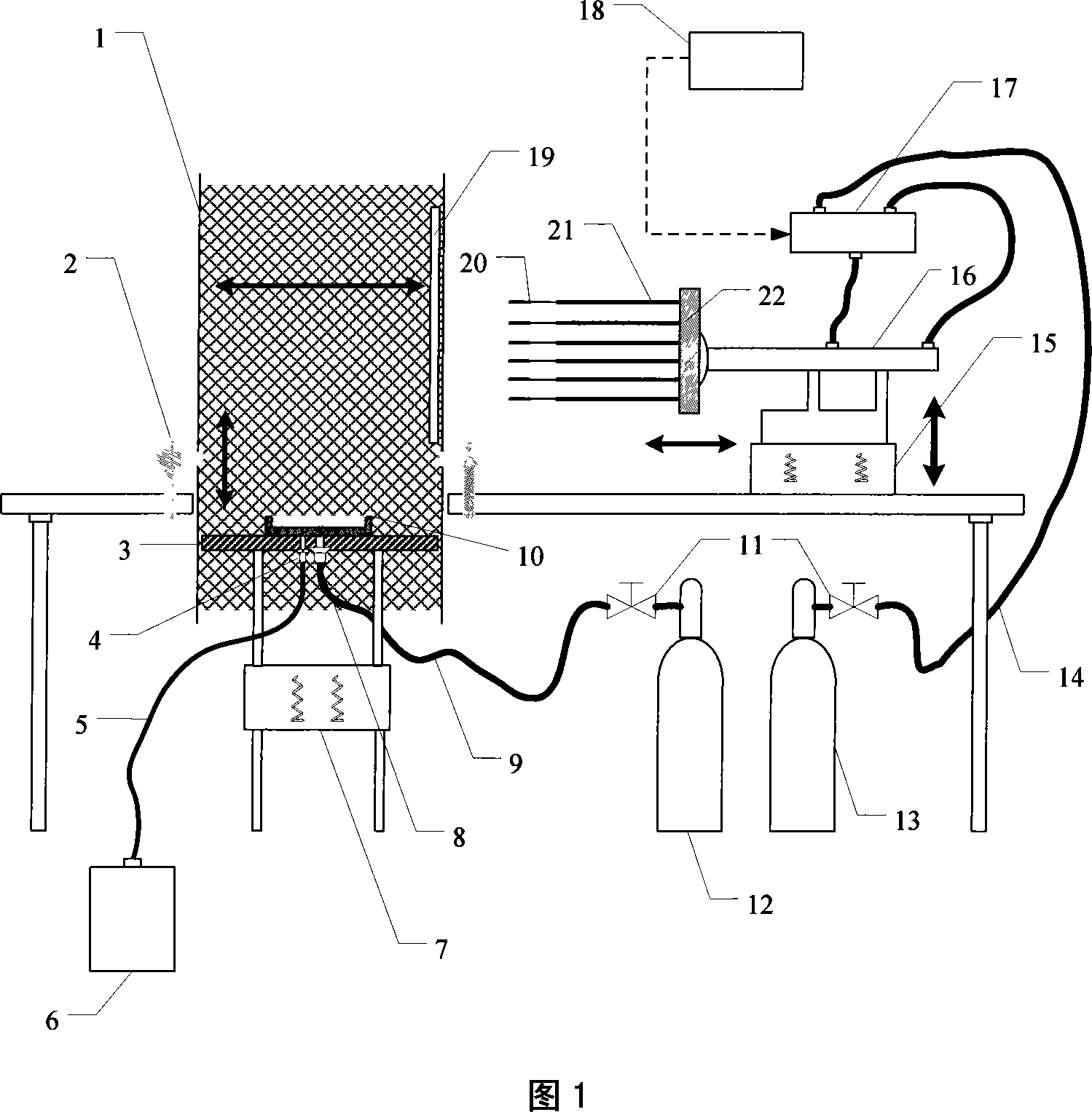

[0024] A high-speed sampling technology and device for experimental fire smoke particles, mainly composed of three parts: a combustion device, a combustion stabilization device, and a combustion product collection device. The combustion device has an opening in the center of the combustion table, and there are The lifting combustion platform 3 is installed on the lifting support 7, the lifting combustion platform 3 has a gas interface 8, the gas interface 8 is connected to the gas supply pipeline 9, and the gas supply pipeline 9 is connected to the gas bottle 12 through the regulating valve 11 Unicom, the regulating valve 11 controls the flow rate to adjust the size of the flame. The gas port 8 of the combustion platform 3 is connected with a nozzle or a plug. The area outside the gas port 8 is the electric heating plate area. 5 is connected to the heating controller 6; another liquid combustion vessel 10 is placed on the combustion platform 3; the combustion stabilization devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com