Horizontal circulation and parallel fluidization chemical looping combustion device

A combustion device and fluidized chemistry technology, which are applied in fluidized bed combustion equipment, fuels burned in a molten state, and combustion methods, etc., can solve the problems of complex system structure, gas leakage, and difficult operation and operation, and achieve simple operation and operation. The effect of eliminating short circuits and improving mixing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

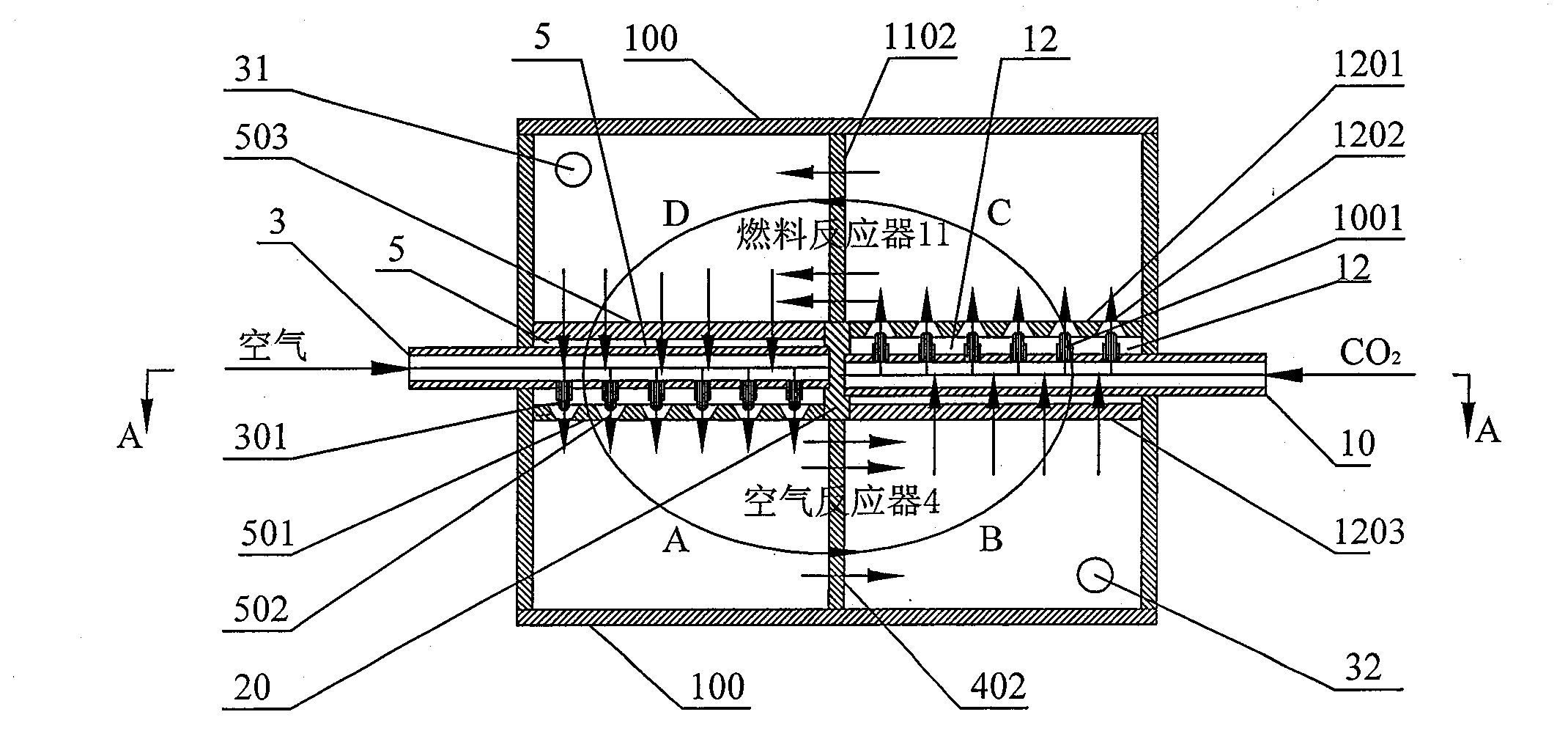

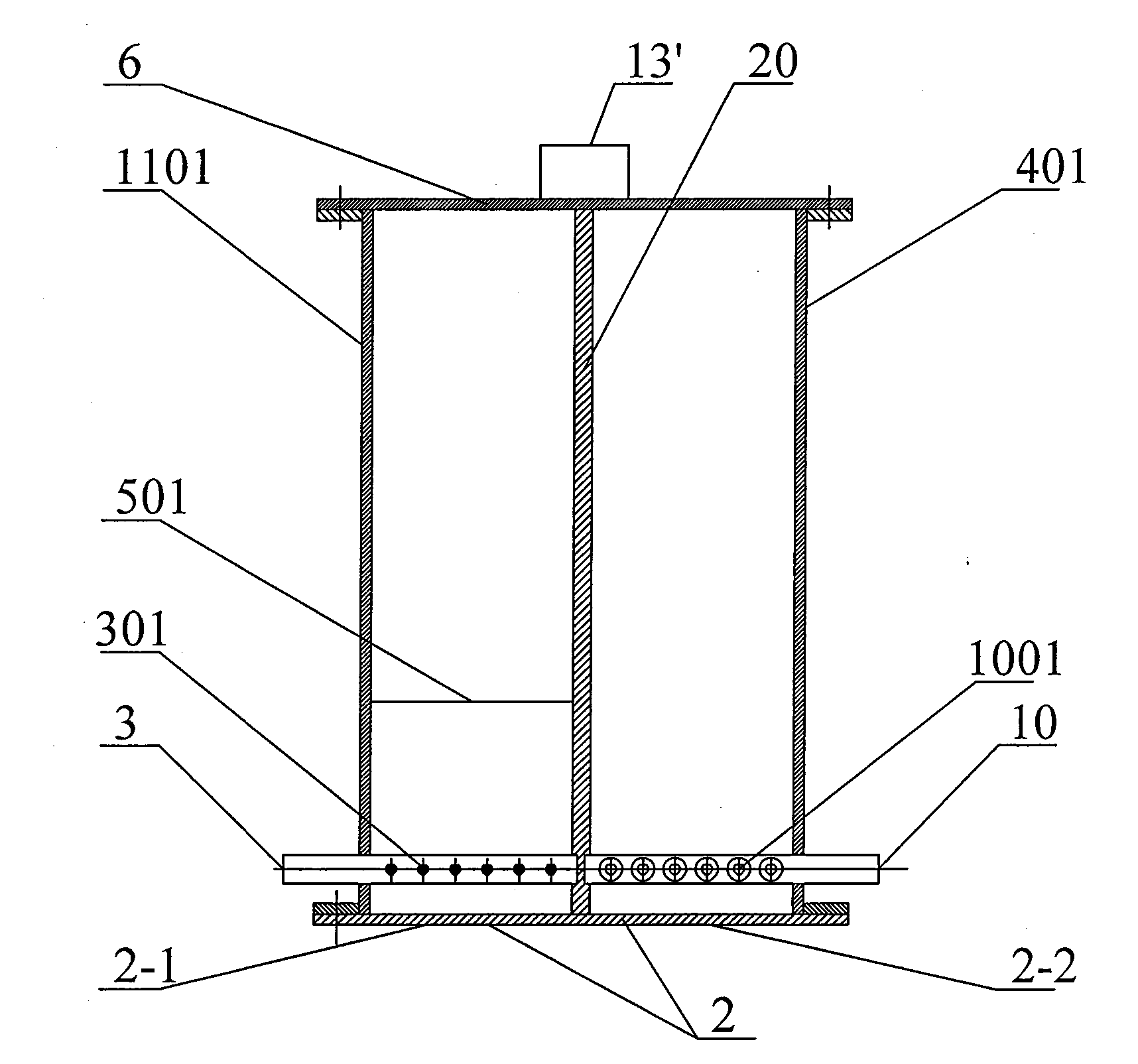

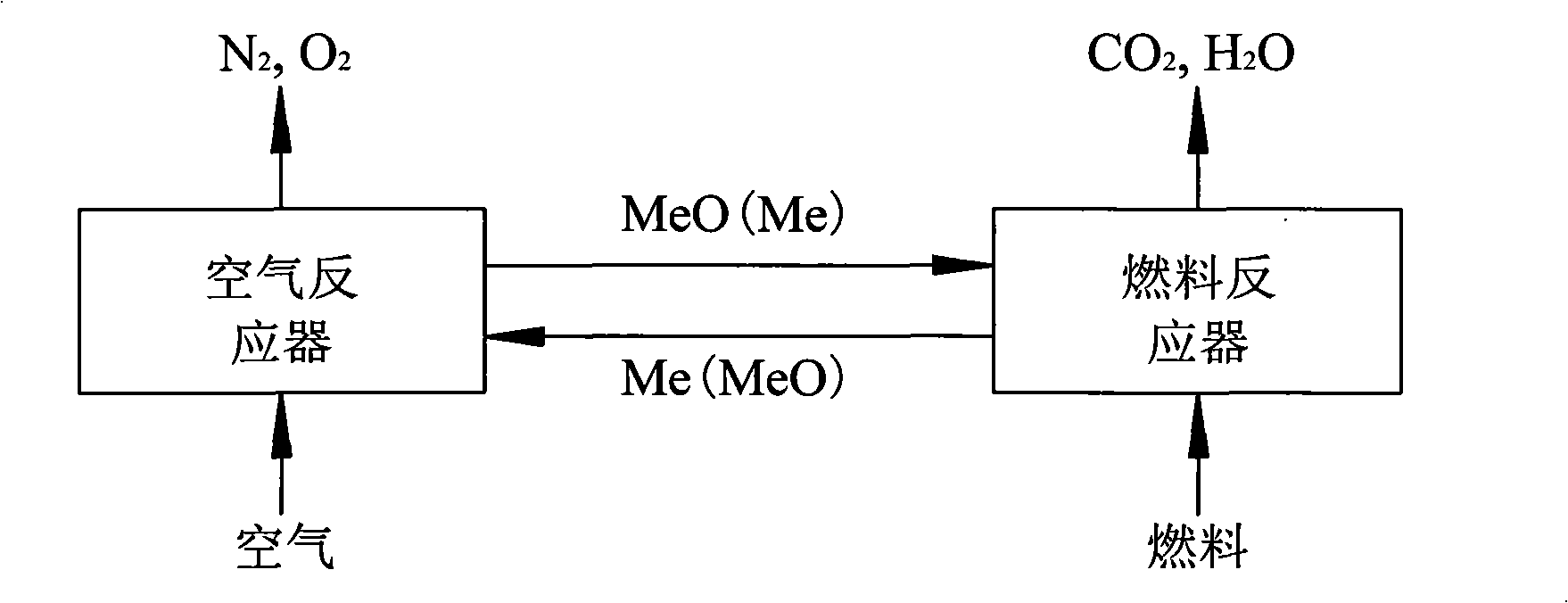

[0019] Such as figure 1 , 2 As shown in , 3, the horizontal circulation parallel fluidized chemical chain combustion device includes a cylinder body 100 of the fluidized bed combustion device, and the bottom of the cylinder body of the fluidized bed combustion device is an air distribution plate 2 . The air distribution plate 2 is equally divided into two (2-1, 2-2), and the first nozzle pipe 3 and the second nozzle pipe 10 are arranged horizontally on both sides of the boundary line of the air distribution plate, and the first nozzle pipe 3 and the second nozzle pipe The ends of 10 are facing each other, several nozzles 301 of the first nozzle pipe and several nozzles 1001 of the second nozzle pipe are arranged horizontally, and the heights of the nozzles of the first nozzle pipe and the nozzles of the second nozzle pipe are all located at the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com