Expansion sleeve joint with double hook shaped thread connection

A technology of expanding casing and threaded connection, applied in the direction of threaded connection, pipe/pipe joint/pipe fitting, casing, etc., to achieve the effect of high strength, elimination of stress concentration, and large friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

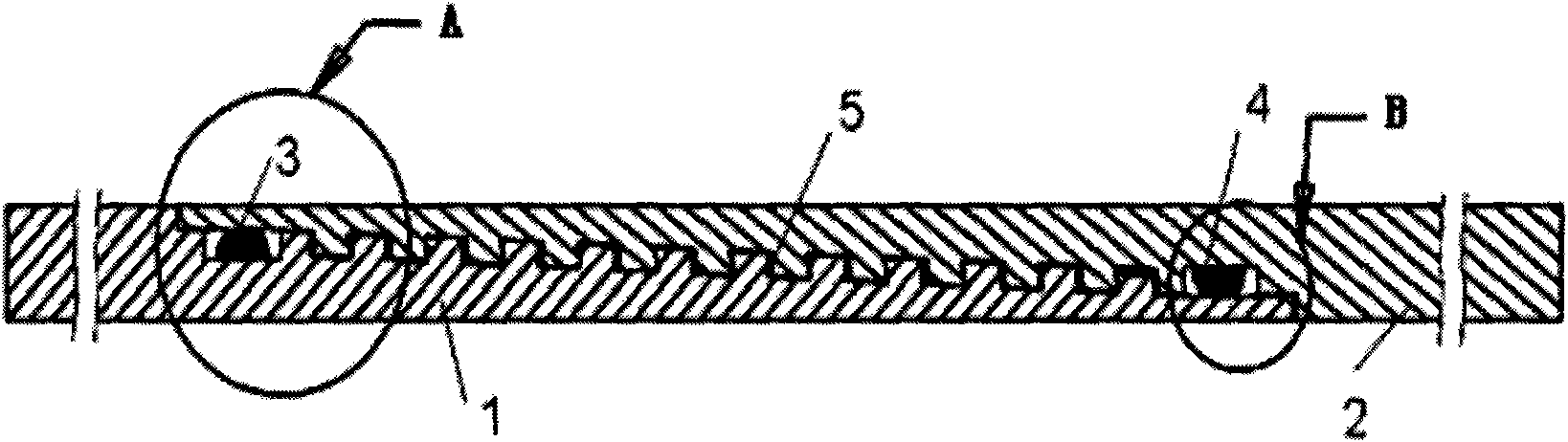

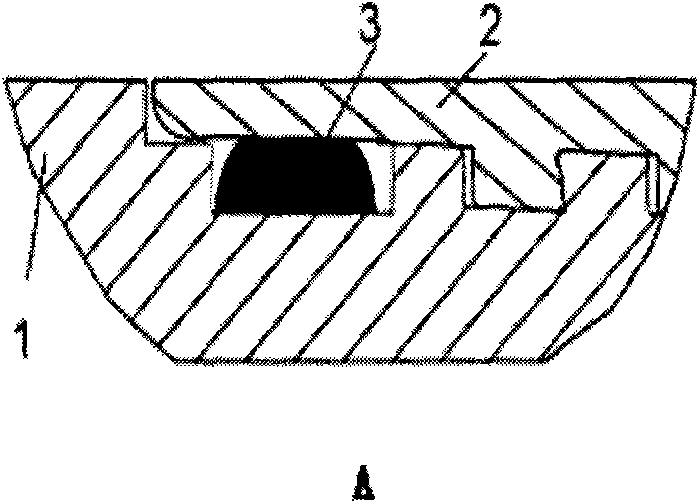

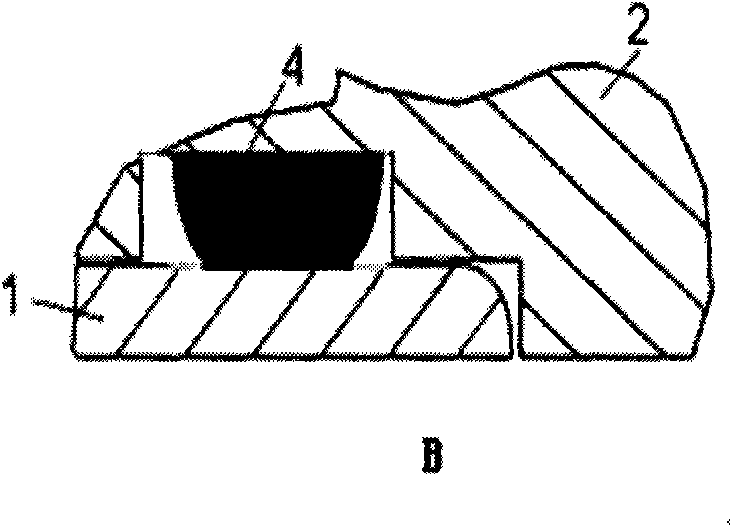

[0019] The structure of the expansion casing joint with double-hook thread connection will be described below according to the accompanying drawings.

[0020] The double-hook-shaped expansion casing joint is composed of a male threaded joint 1 with a hook-shaped thread and a female threaded joint 2. The male threaded joint 1 has a single hook-shaped thread 7 and an outer sealing groove 6 located at the inner end of the male threaded joint 1. and the sealing surface 8 and arc surface 9 at the outer end; the female threaded joint 2 is composed of a single hook-shaped thread groove 15, an inner sealing groove 14 located at the inner end of the female threaded joint 2 and a sealing surface 16 and an arc surface 17 at the outer end, and the corresponding The outer sealing groove 6 at the inner end of the male threaded joint 1 and the sealing surface 8 and the arc surface 9 at the outer end constitute two sealing chambers, and the bowl-shaped rubber outer sealing ring 3 is buckled in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com