Dust removing method and device of cantilever-type comprehensive mechanized development machine

A technology of comprehensive mechanization and dust removal device, which is applied in the direction of slitting machinery, earth drilling and mining, etc., can solve problems such as poor air quality, water accumulation in the working environment, and harsh working environment conditions, so as to improve dust suppression efficiency, reduce dust concentration, The effect of low maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

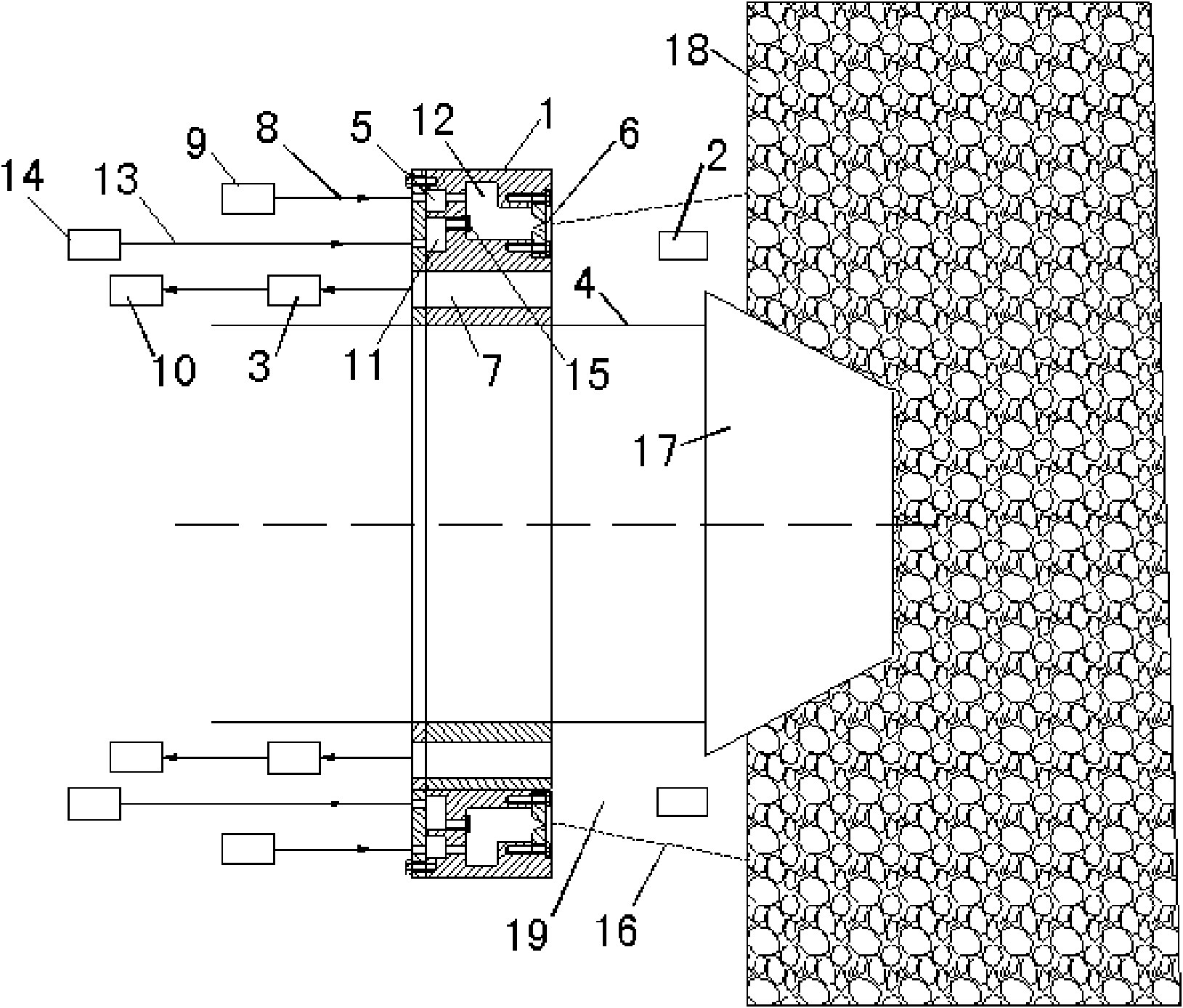

[0015] Example 1. Such as figure 1 As shown, it includes an air cover forming device 1, a spray dust suppression device 2 and a dirty air extracting device 3, and the shield forming device 1 is fixedly installed on the roadhead machine body 4; the air cover forming device 1 is provided with a compressed air cavity 5, an annular nozzle Outlet gap 6, sewage air outlet 7, water chamber 11 and humidification chamber 12. One end of the compressed air chamber 5 is connected to the air compressor 9 through the compressed air delivery pipe 8, and the other end is connected to the annular discharge gap 6; the sewage air outlet 7 is connected to the sewage air extraction device 3, and the sewage air extraction device 3 is connected to the wet dust removal device fan10. The water inlet end of the water chamber 11 is connected to the high-pressure water generator 14 through the high-pressure water delivery pipe 13, and the water outlet end of the water chamber 11 is connected with the h...

Embodiment 2

[0017] Example 2. It includes an air cover forming device 1, a spray dust suppression device 2 and a dirty air extracting device 3. The shield forming device 1 is fixedly installed on the roadhead machine body 4; the air cover forming device 1 is provided with a compressed air chamber 5 and an annular spray gap 6 And sewage air outlet 7. One end of the compressed air chamber 5 is connected to the air compressor 9 through the compressed air delivery pipe 8, and the other end is connected to the annular discharge gap 6; the sewage air outlet 7 is connected to the sewage air extraction device 3, and the sewage air extraction device 3 is connected to the wet dust removal device fan10.

[0018] During use, the high-pressure compressed air produced by the air compressor 9 is sent to the compressed air cavity 5 of the air cover forming device 1 through the compressed air delivery pipeline 8, and is sprayed to the coal rock mass 18 through the annular ejection gap 6. One or more bar...

Embodiment 3

[0019] Example 3. It includes an air cover forming device 1, a spray dust suppression device 2 and a sewage air extraction device 3. The shield forming device 1 is fixedly installed on the roadhead machine body 4; the air cover forming device 1 is provided with an annular spray gap 6 and a sewage air discharge port 7 and water chamber 11 and humidification chamber 12. The sewage air outlet 7 is connected to the sewage air extraction device 3 , and the sewage air extraction device 3 is connected to the wet dust removal fan 10 . The water inlet end of the water chamber 11 is connected to the high-pressure water generator 14 through the high-pressure water delivery pipe 13, and the water outlet end of the water chamber 11 is connected with the humidification chamber 12; an atomized water nozzle 15 is installed on the water outlet end of the water chamber 11; humidification The chamber 12 communicates with the annular discharge gap 6 .

[0020] When in use, the high-pressure water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com