Silicate green long afterglow material and preparation method thereof

A long afterglow material, silicate technology, applied in the direction of luminescent materials, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problem of long afterglow material not rich in luminous color, poor water resistance and stability, and afterglow brightness. It is not strong enough to achieve the effect of remarkable energy saving effect, good thermal stability and good synthesis stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] SrZ 1.999 Si 2 o 7 :Mn 0.001 , B 0.04 Long afterglow luminescent material and raw material ratio figure 1 shown.

[0044] Grind the above ratio thoroughly in an agate mortar, put it into a corundum crucible, compact it, put it into a carbon canister, put it into a high-temperature furnace, heat it to 1300°C, keep the temperature constant for 3 hours, and cool it down to room temperature with the furnace. Near white solid.

[0045] After the material of this embodiment was irradiated with ultraviolet rays for 10 minutes, it showed green afterglow luminescence in the dark; 2 ) above can also emit light for more than 3 hours.

Embodiment 2

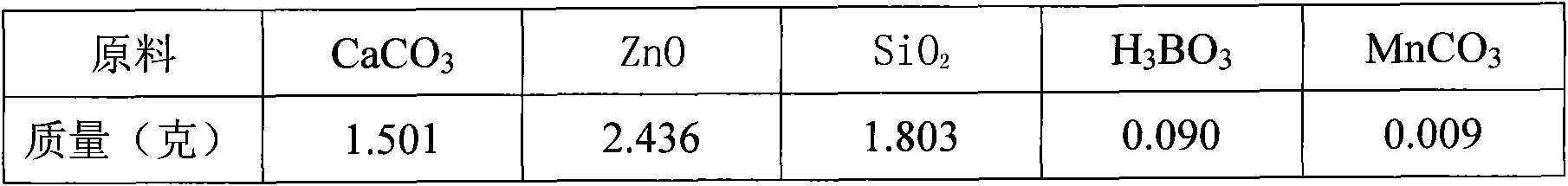

[0047] CaZ 1.995 Si 2 o 7 :Mn 0.005 , B 0.1 Long afterglow luminescent material and raw material ratio figure 2 shown.

[0048] Grind the above ratio thoroughly in an agate mortar, put it into a corundum crucible, compact it, put it into a carbon canister, put it into a high-temperature furnace, heat it to 1200°C, keep the temperature constant for 4 hours, and cool it down to room temperature with the furnace. Near white solid.

[0049] After the material of this embodiment was irradiated with ultraviolet rays for 10 minutes, it showed green afterglow luminescence in the dark; 2 ) above can also emit light for more than 6 hours.

Embodiment 3

[0051] SrZ 1.96 Si 2 o 7 :Mn 0.04 , B 0.6 Long afterglow luminescent material and raw material ratio image 3 shown.

[0052] Grind the above ratio thoroughly in an agate mortar, put it into a corundum crucible, compact it, put it into a high-temperature furnace, heat it to 1000°C, keep the temperature constant for 2 hours, and cool it to room temperature with the furnace to obtain a near-white solid.

[0053] After the material of this embodiment was irradiated with ultraviolet rays for 10 minutes, it showed green afterglow luminescence in the dark; 2 ) above can also emit light for more than 7 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com