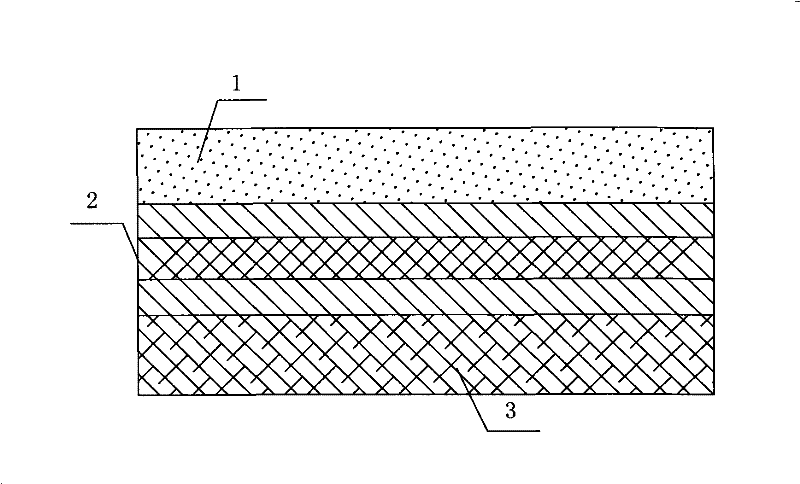

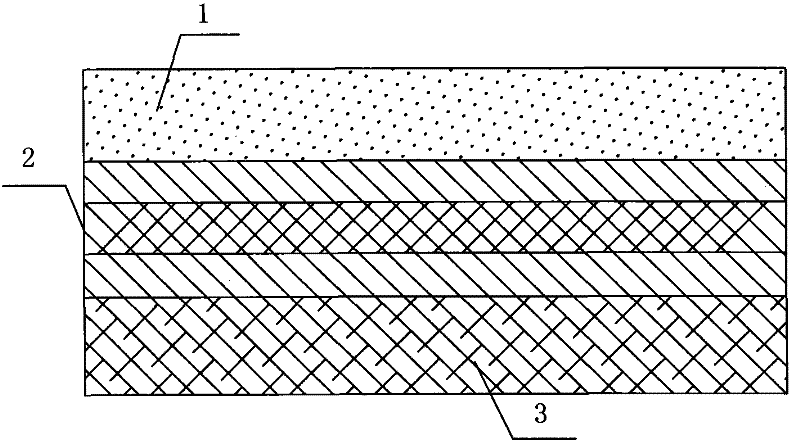

Composite sound-proof formed foaming automobile carpet and preparation method thereof

A technology for car carpets and fabric layers, applied to chemical instruments and methods, synthetic resin layered products, vehicle parts, etc., can solve problems such as poor sound insulation performance, lack of comfort, environmental protection requirements, and large noise, and achieve prevention of PU Foaming breakdown, green environmental performance, anti-puncture and anti-moisture absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of the fabric layer: Take polyester fibers with a weight percentage of 90:10 and fibers with a melting point of 100°C to open and mix them evenly to obtain fibers of a certain color and specification, and then transport the fibers to the carding machine through a material box. The fiber web is obtained by high-speed carding, and the fiber web is then passed through a cross-lapper to form a fiber web of 250 g / m2, and then the fiber web is transported to the needling machine, with a needling depth of 10mm and a needling speed of 3m / min. Acupuncture is carried out according to the conditions, and the fabric layer with an acupuncture density of 120 needles / square centimeter is obtained for subsequent use.

[0021] The preparation of the bottom material layer: take the polyester fiber with a weight percentage of 75:25 and the fiber with a melting point of 100°C to open and mix evenly to obtain fibers of a certain color and specification, and then transport the fib...

Embodiment 2

[0024] The preparation of the fabric layer: take the polyester fiber with a weight percentage of 92:8 and the fiber with a melting point of 110°C to open and mix evenly to obtain fibers of a certain color and specification, and then transport the fibers to the carding machine through the material box. The fiber web is obtained by high-speed carding, and the fiber web is then passed through a cross-lapper to form a fiber web of 430 g / m2, and then the fiber web is transported to the needling machine, with a needling depth of 13mm and a needling speed of 5m / min. Acupuncture is carried out according to the conditions, and the fabric layer with an acupuncture density of 500 needles / square centimeter is obtained for subsequent use.

[0025] Preparation of the bottom material layer: Take polyester fibers with a weight percentage of 45:55 and fibers with a melting point of 110°C to open and mix them evenly to obtain fibers of a certain color and specification, and then transport the fi...

Embodiment 3

[0028] The preparation of the fabric layer: take the polyester fiber with a weight percentage of 96:4 and the fiber with a melting point of 120°C to open and mix evenly to obtain fibers of a certain color and specification, and then transport the fibers to the carding machine through the material box. The fiber web is obtained by high-speed carding, and the fiber web is then passed through a cross-lapper to form a 600 g / m2 fiber web, and then the fiber web is transported to the needling machine, with a needling depth of 12mm and a needling speed of 4m / min. Acupuncture is carried out according to the conditions, and the fabric layer with an acupuncture density of 300 needles / square centimeter is obtained for subsequent use.

[0029] The preparation of the bottom material layer: take the polyester fiber with a weight percentage of 55:45 and the fiber with a melting point of 120°C to open and mix evenly to obtain fibers of a certain color and specification, and then transport the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com