Four-way valve used for adsorption drier

A technology of adsorption dryer and four-way valve, which is applied in the field of four-way valve, can solve the problems of high production cost, unstable performance, complicated connection of parts, etc., and achieve the effect of reducing production cost, improving stability and performance, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

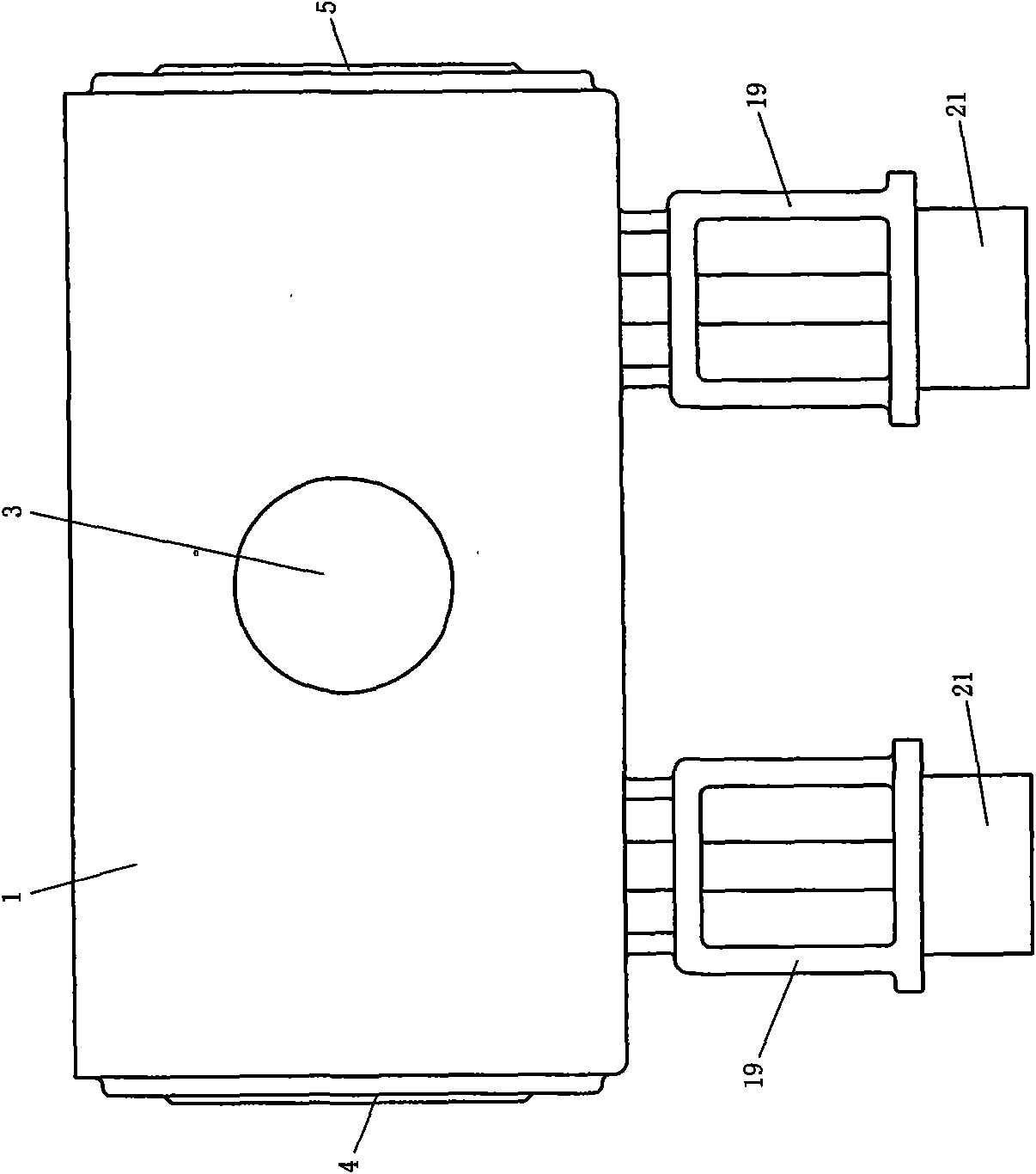

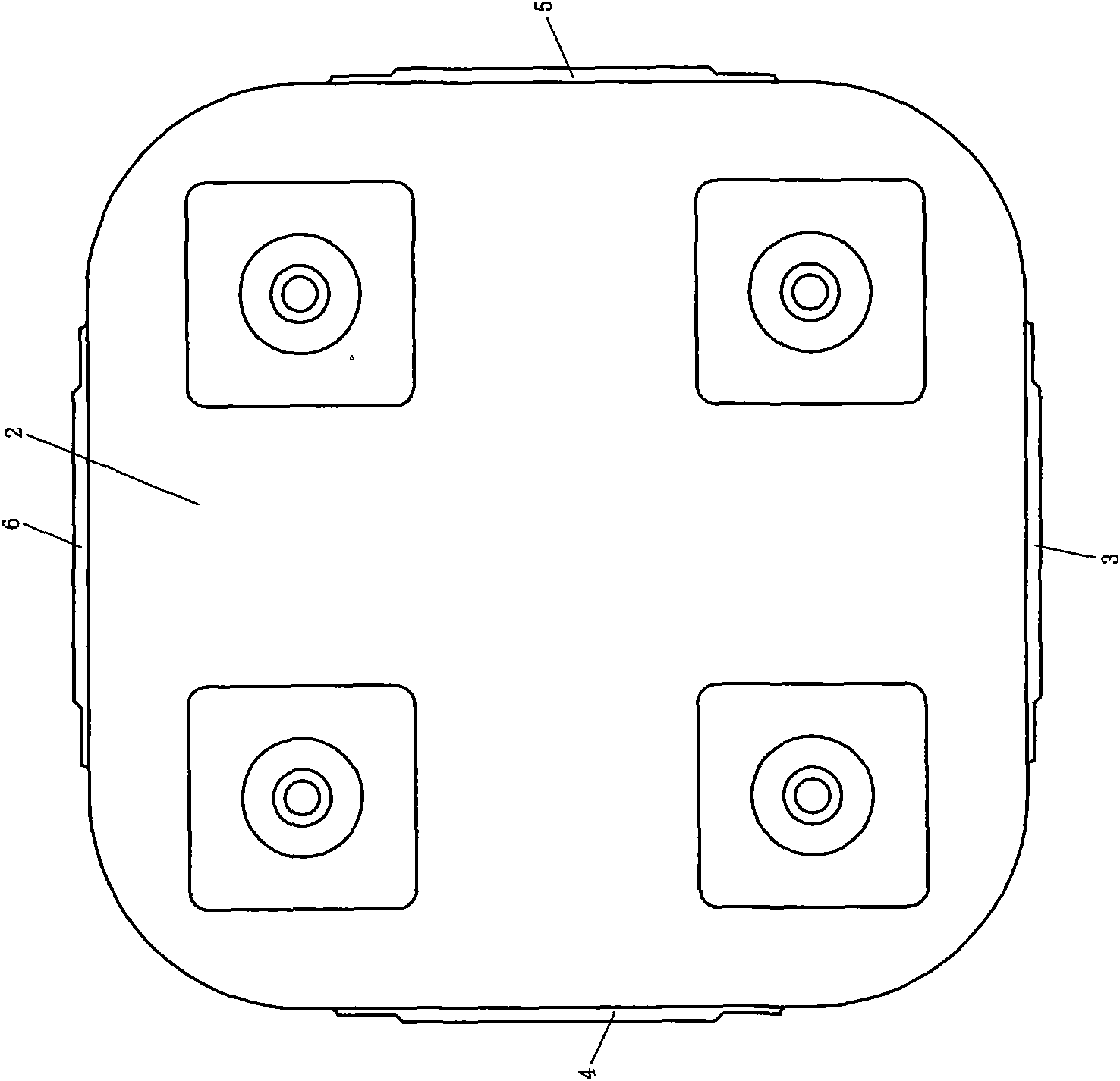

[0013] Example: see figure 1 and figure 2 A valve cover 2 is arranged on the valve body 1 of the present invention, an air inlet 3 is arranged on the front side wall of the valve body 1, an exhaust gas outlet 6 is arranged on the rear side wall opposite to the air inlet 3, and left and right sides are respectively arranged on the left and right side walls. The air outlet 4 and the right air outlet 5 are provided with four valve seats 19 on the bottom side of the valve body 1 .

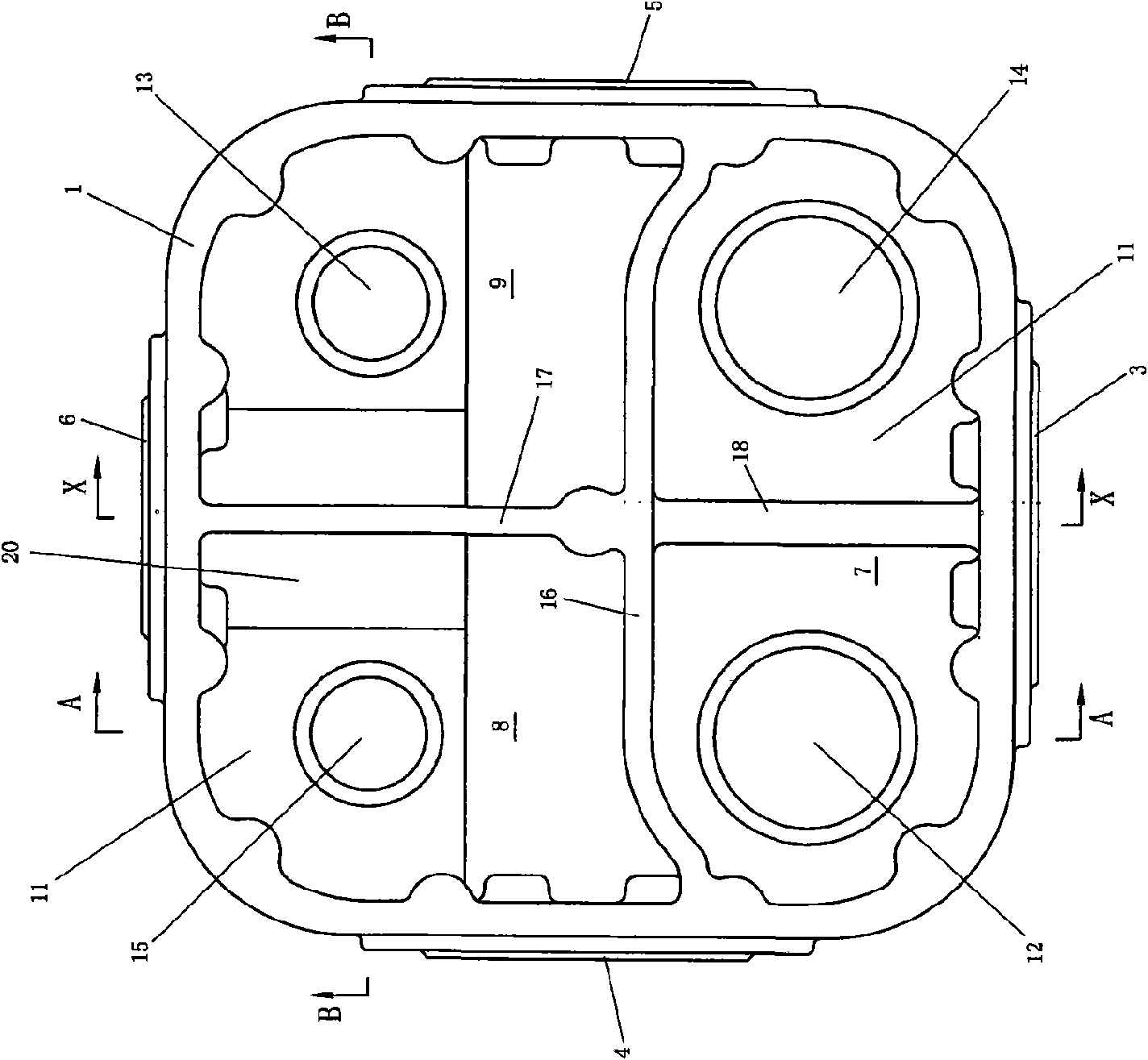

[0014] see image 3 , Figure 4 , Figure 5 and Figure 6 , the air inlet 3 is connected to the air inlet chamber 7, the left air outlet 4 is connected to the left air outlet chamber 8, the right air outlet 5 is connected to the right air outlet chamber 9, the exhaust gas outlet 6 is connected to the exhaust gas chamber 10, the left air outlet chamber 8 and the right air outlet The cavity 9 is isolated by the second partition 17 , in order to strengthen the mechanical strength of the structure, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com