Three-dimensional reconstruction based explosive fluidity measuring method

A measurement method and three-dimensional reconstruction technology, which is applied in the directions of measuring devices, 3D image processing, image data processing, etc., can solve the problem of inability to specifically or quantitatively determine the fluidity, affect the production efficiency of the explosive charging process, and affect the efficiency of the packaging process, etc. problem, to achieve fast calculation speed, intuitive measurement results, and speed-up effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

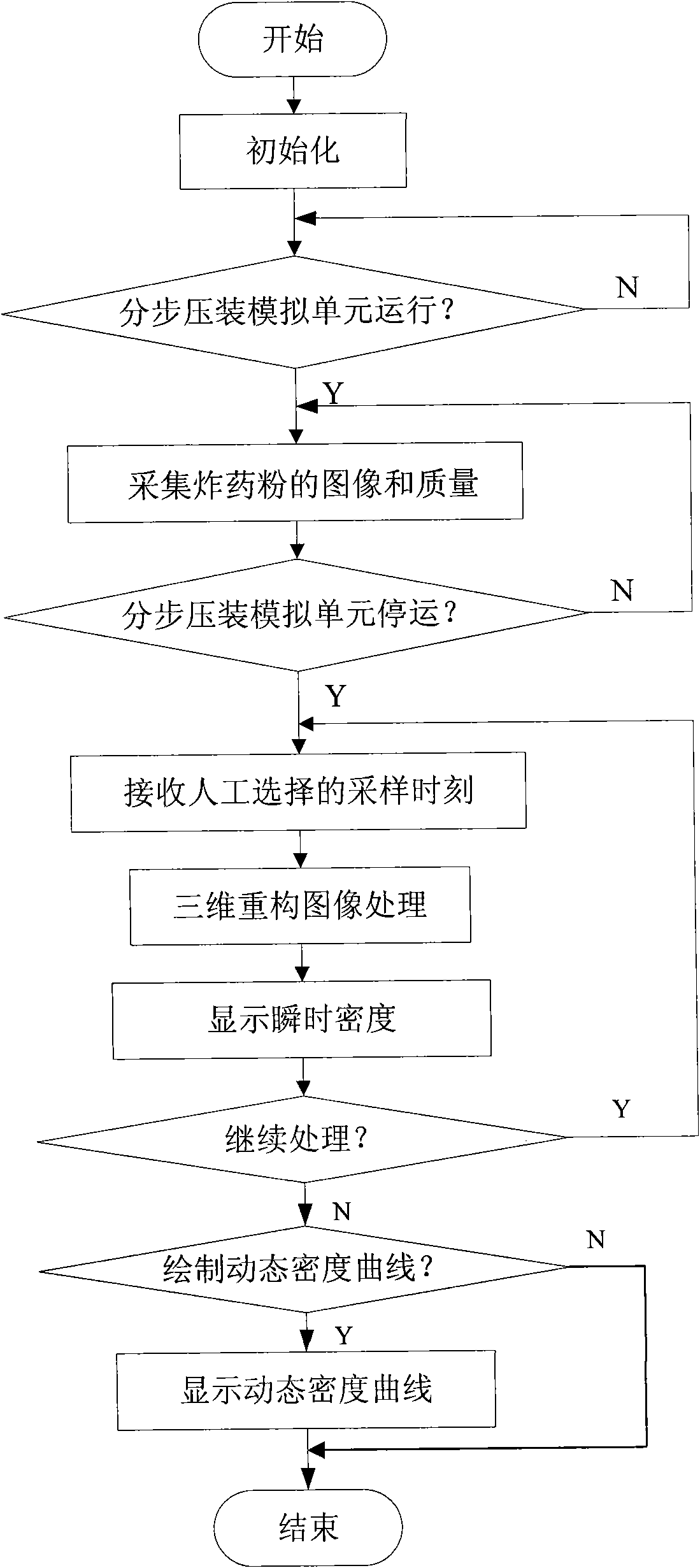

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

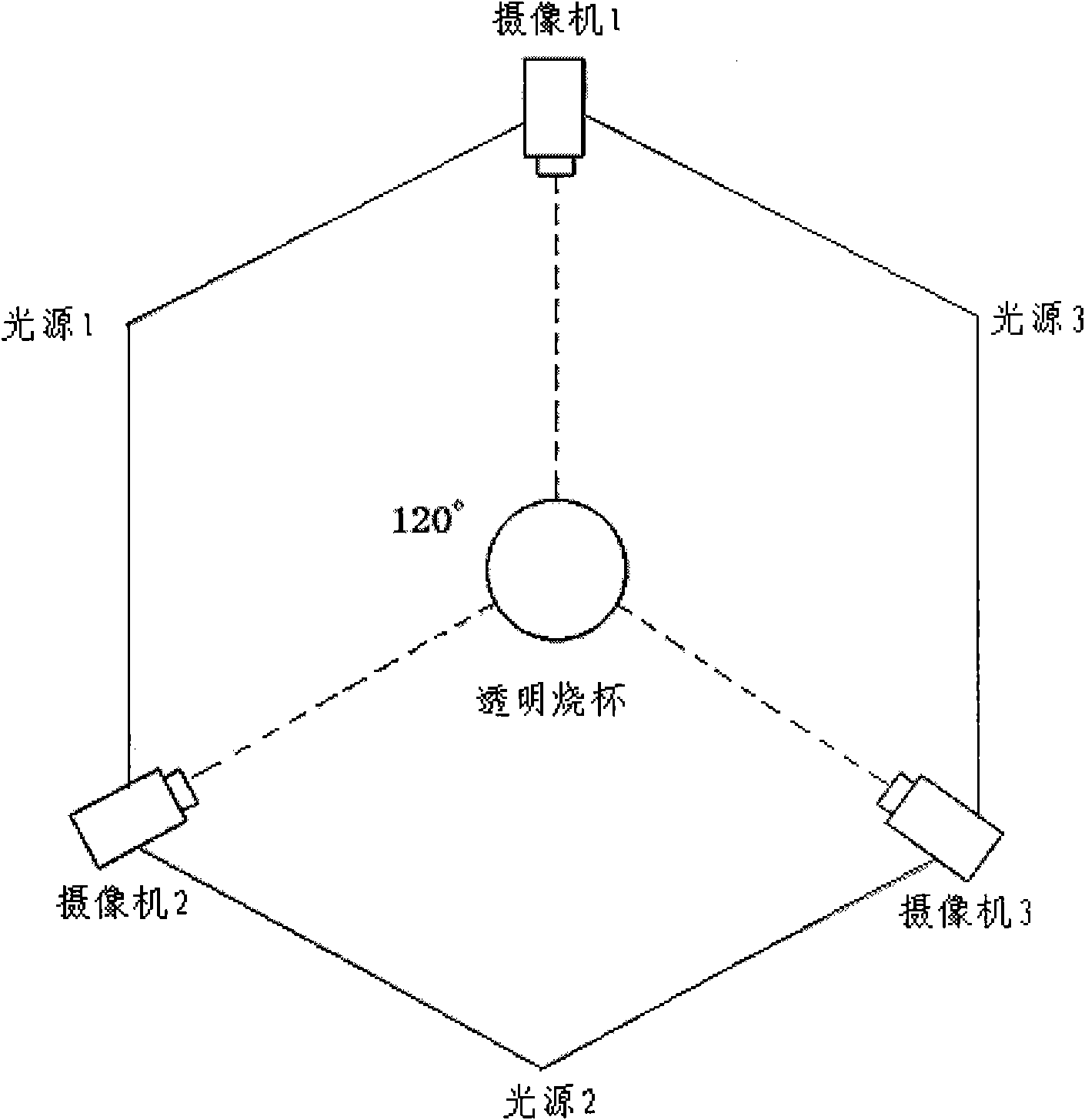

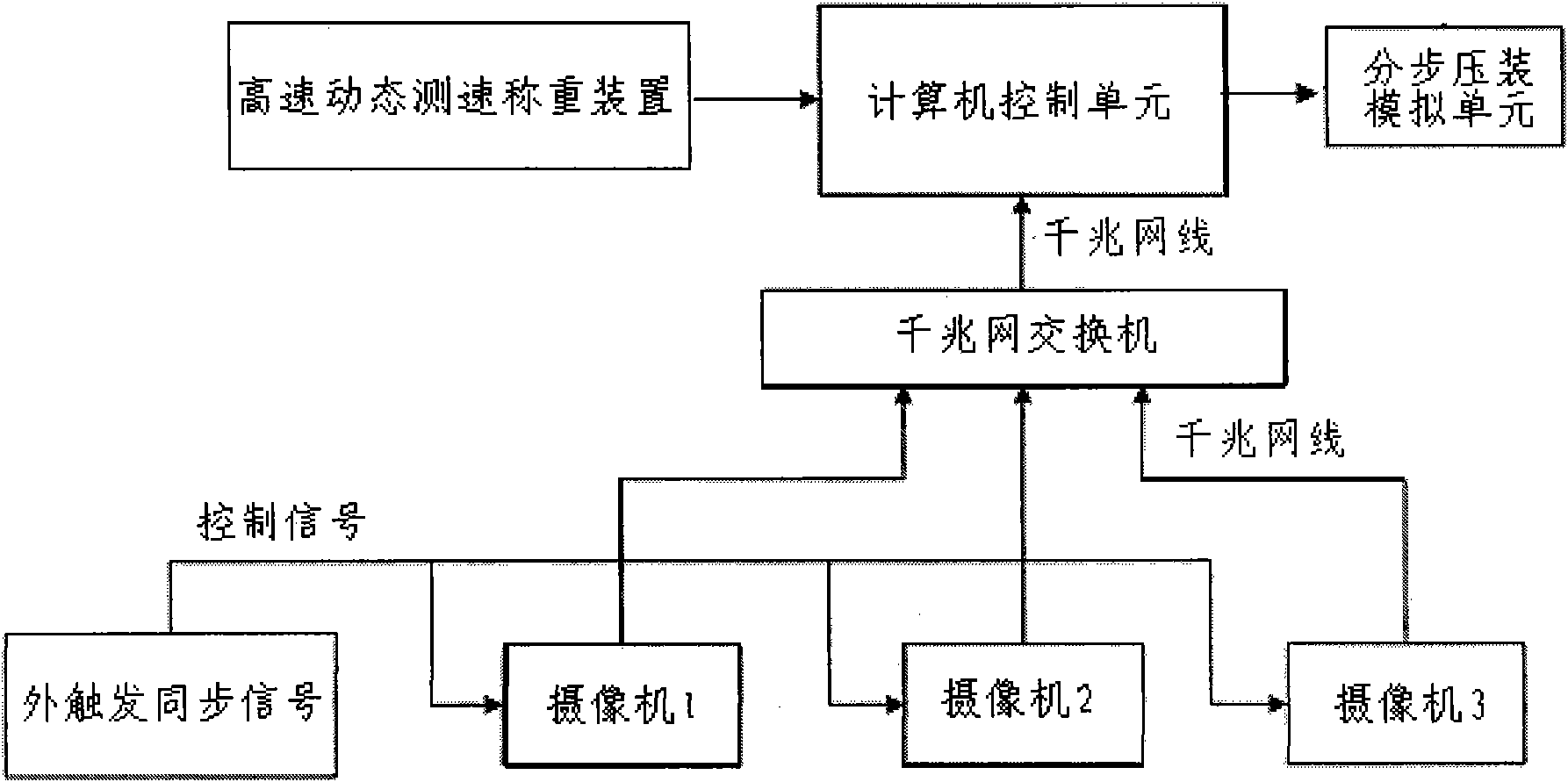

[0032] The main task of the invention is to provide a data analysis and processing method for the explosive fluidity measuring device by means of software, and finally obtain the fluidity characteristic of the explosive. It can be seen that the explosive dynamic data obtained by the explosive fluidity measuring device is the basis and processing object of the present invention. As mentioned in the background art, an important function of the explosive fluidity measuring device is to simulate the drug delivery process of the step-by-step press-packing process, and obtain relevant explosive dynamic data during the simulated drug delivery process through corresponding measures. For this reason, in addition to the step-by-step press-fit simulation unit and computer control unit that can simulate the step-by-step press-fit process, the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com