Novel electronic control carburetor electromagnetic valve

A solenoid valve, carburetor technology, applied in electrical control, engine control, fuel injection control, etc., can solve the problem of difficulty in identifying the normal operation and operation of the solenoid valve, inconvenient installation of LED indicators, and increased installation and manufacturing costs, etc. problems, to achieve the effect of reducing the emission of harmful gases and substances, reducing the volume and size, and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

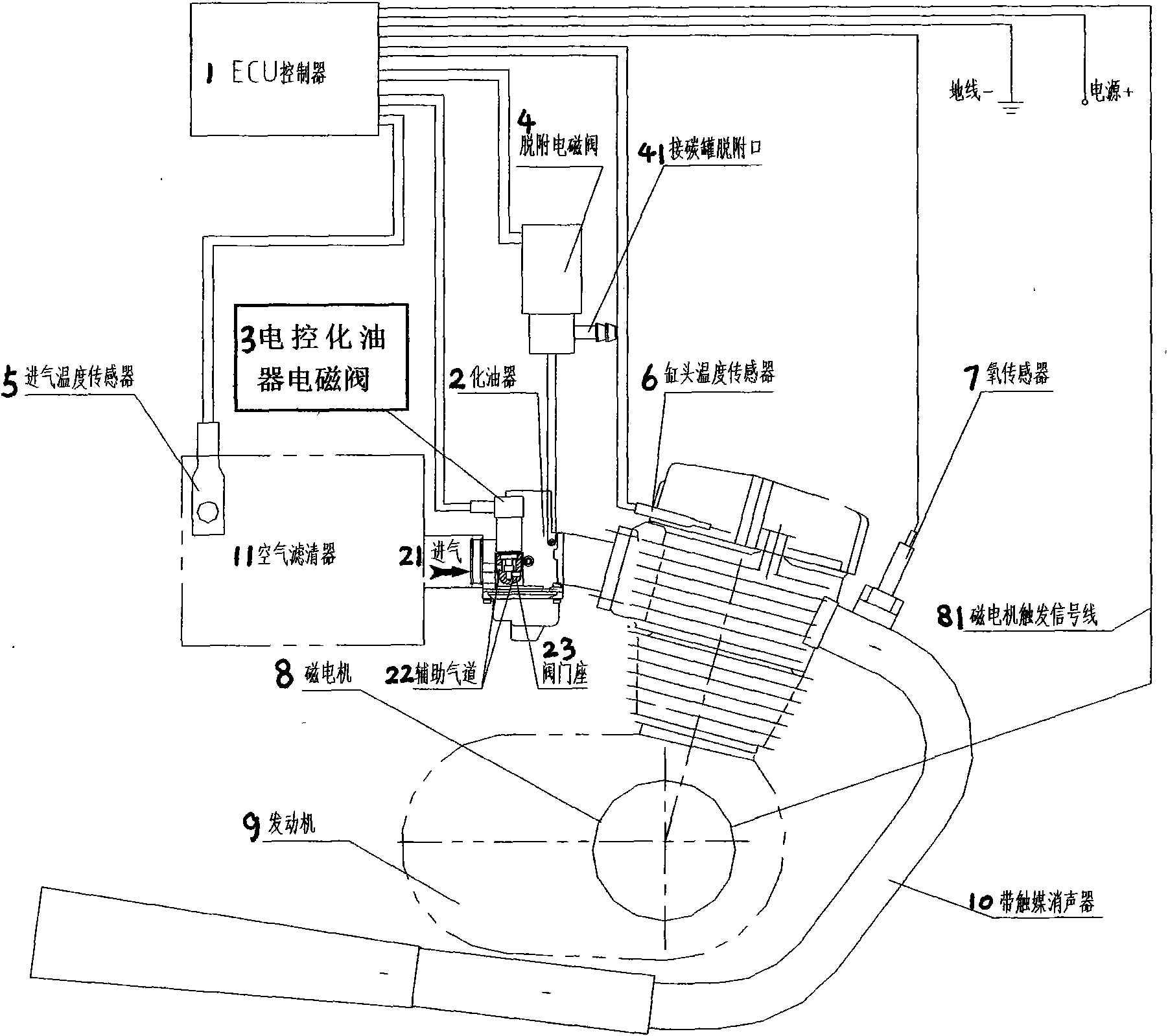

[0022] see figure 1 As shown in the schematic diagram of the carburetor electronically controlled integrated system, 1. The electronic controller (ECU) communicates with the electronically controlled carburetor solenoid valve 3, the desorption solenoid valve 4, the intake air temperature sensor 5, and the cylinder head temperature sensor 6 through signal lines. , the oxygen sensor 7 is connected; the magneto trigger signal line 81 is connected to the magneto 8 . The electronically controlled carburetor solenoid valve 3 is installed and fixed on the valve seat 23 of the carburetor 2 . The probe of the intake air temperature sensor 5 is installed on the air intake of the air cleaner 11 . The probe of cylinder head temperature sensor 6 is installed on the cylinder head position of engine 9 . The probe of oxygen sensor 7 is installed on the exhaust port of engine 9 .

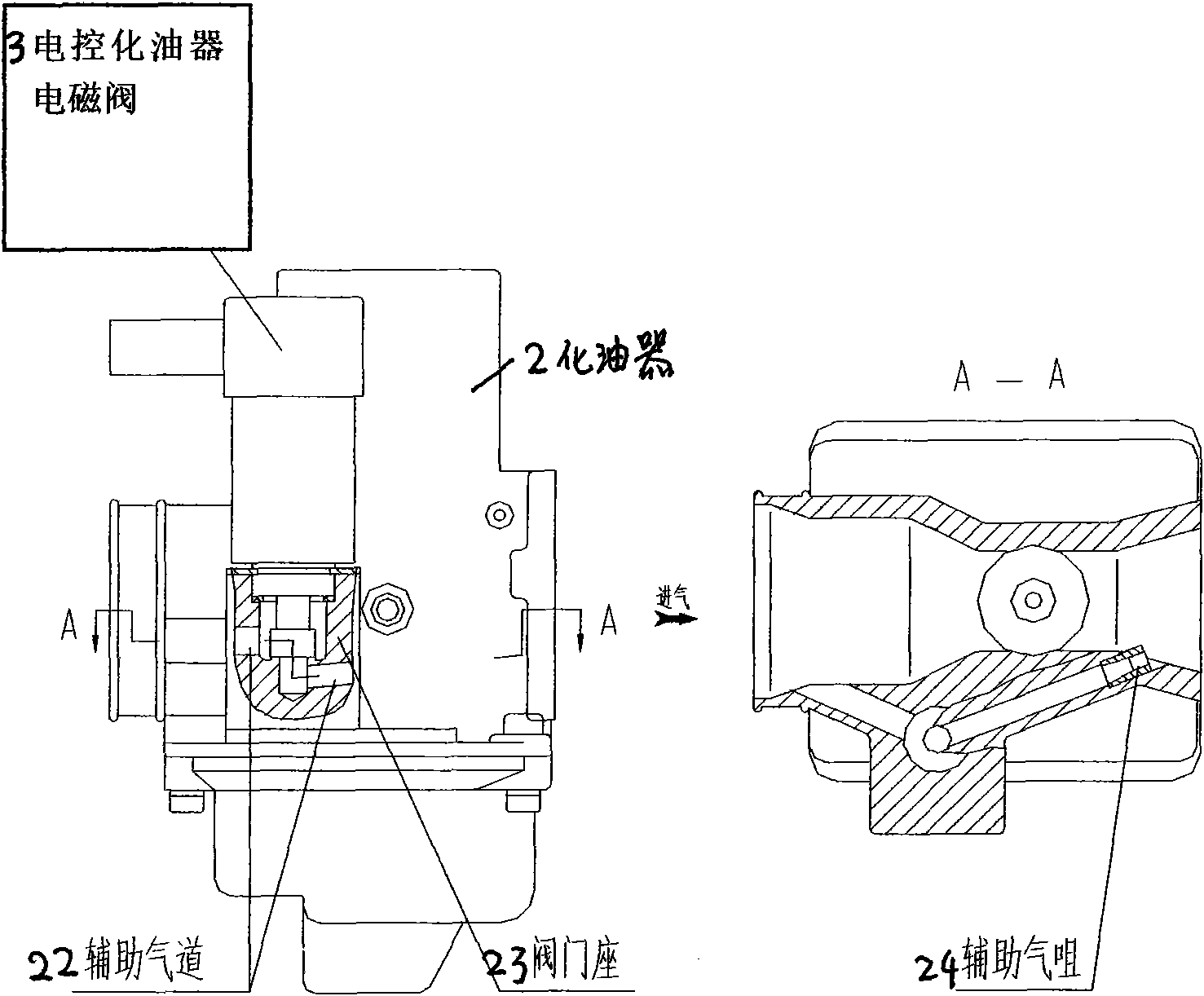

[0023] see figure 2 As shown in the schematic diagram of the integration of the new carburetor and the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com