Method for jointly controlling emission of NOx by utilizing multi-stage bias combustion and fuel reburning

A thick-lean combustion, combined control technology, applied in the combustion method, the use of multiple fuel combustion, the use of lump fuel and liquid fuel combustion, etc., can solve problems such as restricting development, optimize ignition conditions, and reduce boiler slagging. , The effect of efficiently controlling NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

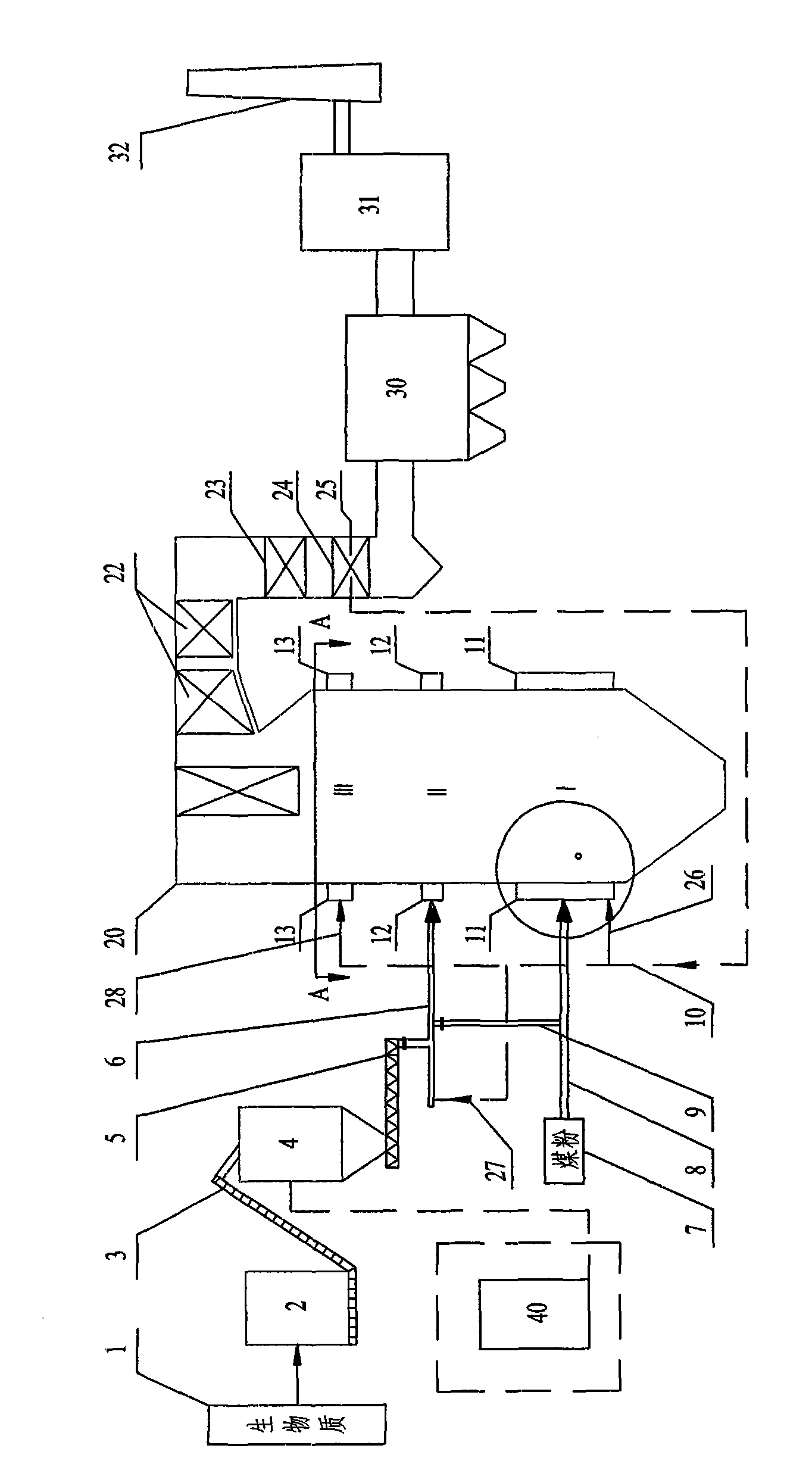

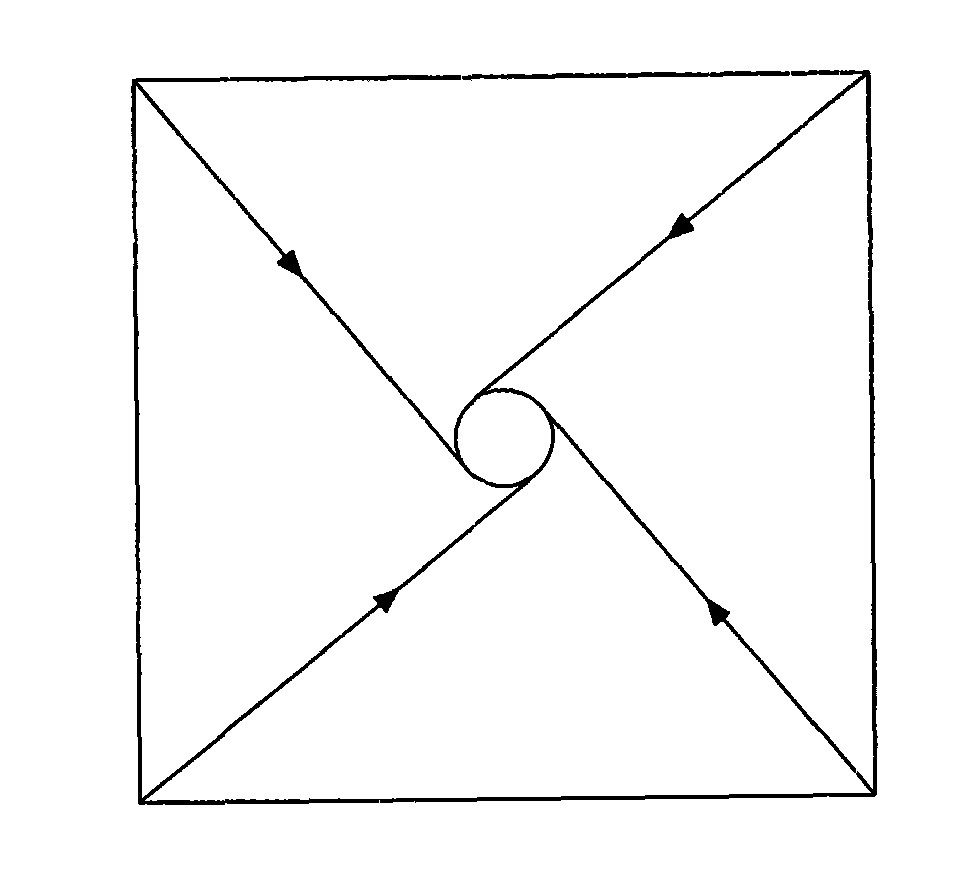

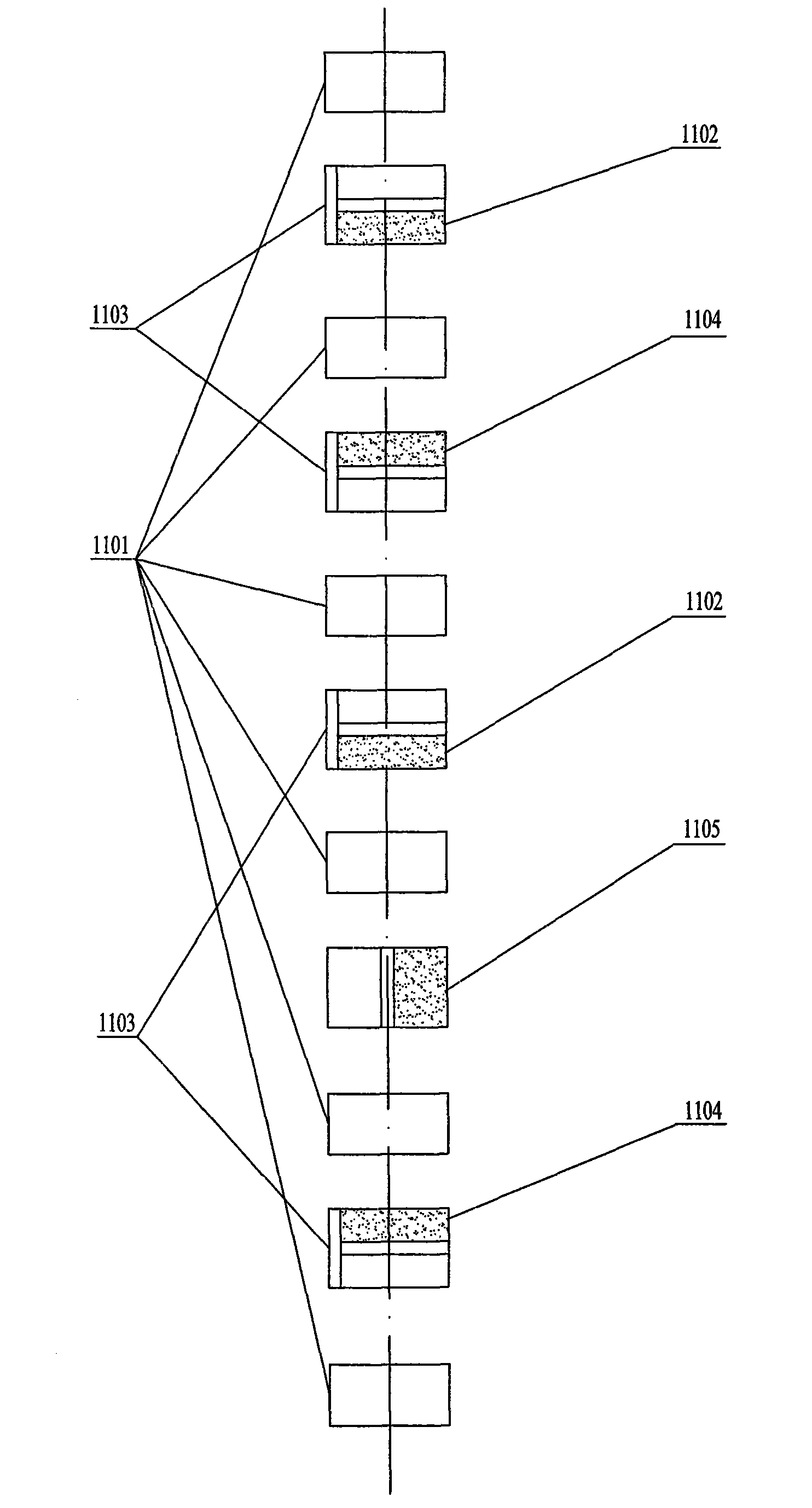

[0018] The device of this embodiment is as figure 1 As shown, the pulverized coal 7 of the pulverizing system of the power plant boiler is divided into two paths through the primary air pipe 8, which are respectively connected with the reburning fuel connecting pipe 6 and the furnace multi-stage thick-lean burner 11. The multi-stage thick-lean burner is arranged at the four corners of the furnace to The tangential form is sprayed into the multi-stage thick-lean combustion zone I in the furnace, forming a tangent circle of φ450~900mm in the center of the furnace, such as figure 2 shown. Multi-stage rich-lean burner 11 such as image 3 As shown, there are 11 layers of spouts in total, and the furnace includes 5 layers of rich-lean burners from bottom to top, of which the first and fourth layers are upper-rich and lower-lean burners 1104 and are deflected upward by 4 to 6 degrees, and the second layer is horizontal thick-lean burners. Burner 1105, the third and fifth floors ar...

Embodiment 2

[0023] In this embodiment, multi-stage rich-lean combustion and mixed fuel reburning are used to jointly control NO x The difference between the discharge method and embodiment 1 is the arrangement of the rich-lean burner, Figure 4 A schematic diagram of the arrangement of the second multi-stage rich-lean burner is given. The rich-lean burner has five layers of nozzles, two of which are rich-lean burners (lower thicker upper thinner type 1102 and upper thicker lower thinner type 1104). Side air 1103 is provided on the side and backfire side of the rich-lean burner, and the other three layers are secondary air nozzles 1101, which are respectively arranged between the rich-lean burners. This type of burner has a low arrangement height, which is suitable for pulverized coal boilers with small capacity.

Embodiment 3

[0025] In this embodiment, multi-stage rich-lean combustion and mixed fuel reburning are used to jointly control NO x The difference between the discharge method and that of Example 1 lies in the preparation and feeding of biomass reburned fuel. When in use, the purchased granular biomass reburning fuel is stored in the reburning fuel storage bin 40 and transported to the intermediate feeding bin 4 by means of pneumatic conveying. This embodiment cancels the pretreatment of biomass, and the system is simpler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com