Method for producing three-color light-emitting diode for display screen

A technology of light-emitting diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as poor pixel repeatability, and achieve the effects of improving pixel resolution, saving energy, and having a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

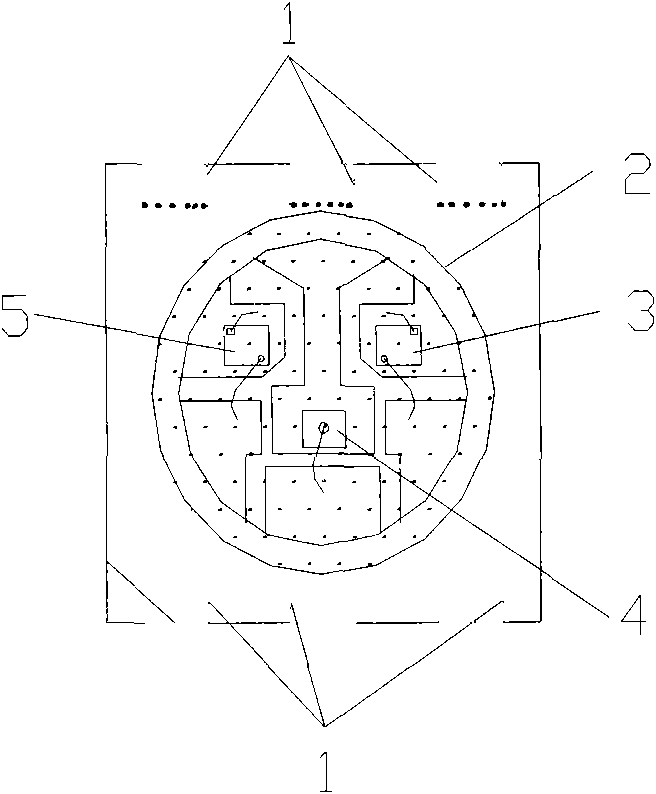

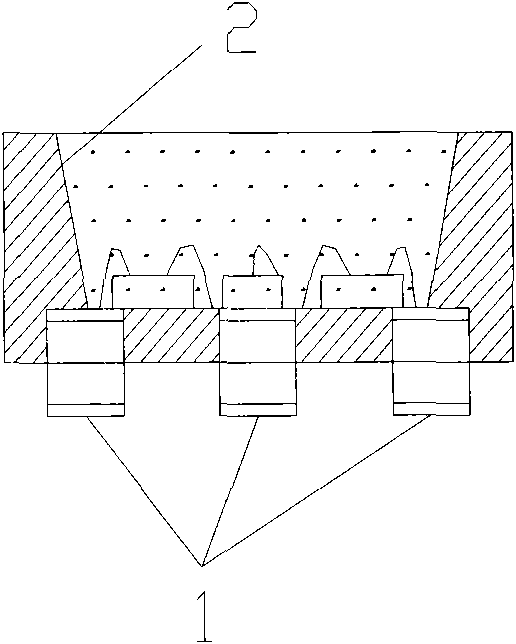

[0027] Firstly, adopt the bracket whose bottom of the reflective cup body is not on the same plane; that is, sink down at least one height at any position of the bottom of the reflective cup body to form a bracket for a small reflective cup that can be placed with one or more tricolor LED light-emitting chips Above, thicken the frame composed of the cup body (6), each pole lead wire (7), (8), (9), (10) to more than 1.2mm; position, use wires to connect the chip electrodes with the lead frame; finally use the overall transparent epoxy resin to package into various shapes and shapes according to different requirements; if surface mount is used, then bend from (19), and then For surface mount, over reflow soldering.

[0028] The plane for fixing the illuminants of the three-primary-color LED light-emitting chips is non-planar, and at least one position (13) is not on the same plane as the fixing positions (21) of the luminous bodies of other primary-color LED light-emitting chips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com