Method for preparing capacity-increased and energy-saving overhead power transmission shaped conductor

A power overhead, energy-saving technology, used in cable/conductor manufacturing, other manufacturing equipment/tools, circuits, etc., can solve problems such as inability to increase transmission capacity, large surface roughness, and large material loss, and improve material utilization. , The appearance is smooth and round, the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

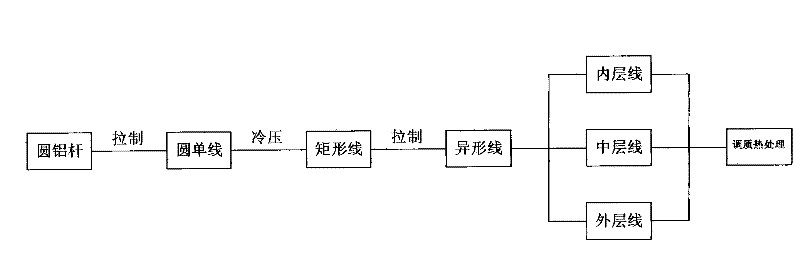

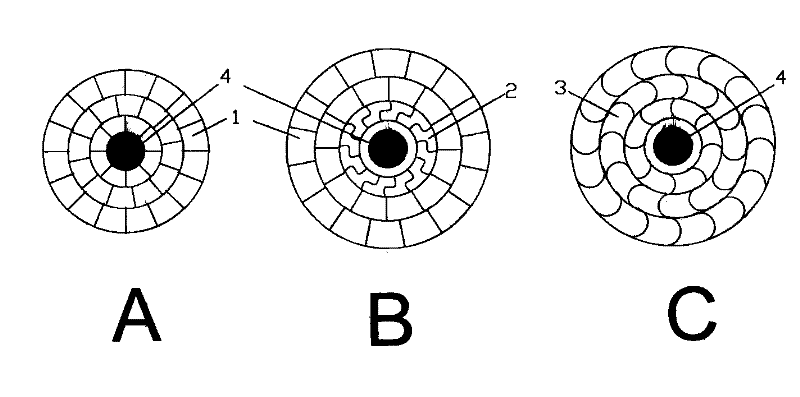

[0028] according to Figure 1-3 As shown, a method for preparing a capacity-increasing and energy-saving special-shaped wire for overhead power transmission, the steps are as follows:

[0029] 1. A round aluminum rod with a diameter of 9.5mm is manufactured after melting the aluminum base, and the component weight of the aluminum base material is kg:

[0030] Si 0.06

[0031] Fe 0.15

[0032] Cu 0.05

[0033] Mg 0.08

[0034] Cr 0.003

[0035] Mn 0.004

[0036] Ti 0.005

[0037] V 0.002

[0038] Al 99.646

[0039] When the impurity content exceeds 0.015kg, boron is added for boronization process;

[0040] 2. It is made into a round single wire of Φ5.0mm through a multi-channel circular hole die drawing process;

[0041] 3. The above-mentioned round single wire is rolled into a rectangular wire of the required size through a cold-pressed roll;

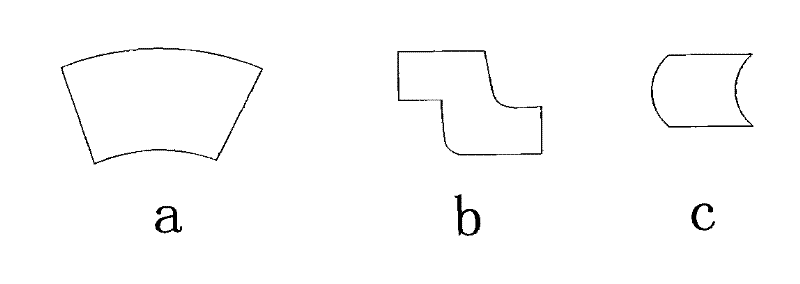

[0042] 4. The rectangular wire is drawn through three special-shaped wire drawing dies image 3 -a profiled aluminum singl...

Embodiment 2

[0047] according to Figure 1-3 As shown, a method for preparing a capacity-increasing and energy-saving special-shaped wire for overhead power transmission, the steps are as follows:

[0048] 1. A round aluminum rod with a diameter of 12mm is manufactured after melting the aluminum base, and the component weight of the aluminum base material is kg:

[0049] Si 0.10

[0050] Fe 0.10

[0051] Mg 0.01

[0052] Cr 0.001

[0053] Mn 0.002

[0054] Ti 0.003

[0055] V 0.004

[0056] Al 99.78

[0057] When the impurity content exceeds 0.015kg, boron is added for boronization process;

[0058] 2. It is made into a round single wire of Φ6mm through a multi-channel circular hole die drawing process;

[0059] 3. The above-mentioned round single wire is rolled into a rectangular wire of the required size through a cold-pressed roll;

[0060] 4. The rectangular wire is drawn through three special-shaped wire drawing dies image 3 -b shows profiled aluminum single wire, as fig...

Embodiment 3

[0065] according to Figure 1-3 As shown, a method for preparing a capacity-increasing and energy-saving special-shaped wire for overhead power transmission, the steps are as follows:

[0066]1. A round aluminum rod with a diameter of 12mm is manufactured after melting the aluminum base, and the component weight of the aluminum base material is kg:

[0067] Si 0.08

[0068] Fe 0.12

[0069] Cu 0.07

[0070] Cr 0.002

[0071] Mn 0.003

[0072] Ti 0.004

[0073] V 0.003

[0074] Al 99.718

[0075] When the impurity content exceeds 0.015kg, boron is added for boronization process;

[0076] 2. It is made into a round single wire of Φ6.5mm through a multi-channel round hole die drawing process;

[0077] 3. The above-mentioned round single wire is rolled into a rectangular wire of the required size through a cold-pressed roll;

[0078] 4. The rectangular wire is drawn through three special-shaped wire drawing dies image 3 -C profiled aluminum single wire, as figure 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com