Transformer substation aluminum tube supporting type expanded-diameter heat resistant aluminum alloy bus

A technology of expanding the bus bar and supporting type, which is applied in the direction of circuits, power cables, electrical components, etc., can solve the problems of low twisting tightness, limited use, and increased electric field strength on the bus surface, so as to improve the twisting tightness, increase effect of diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

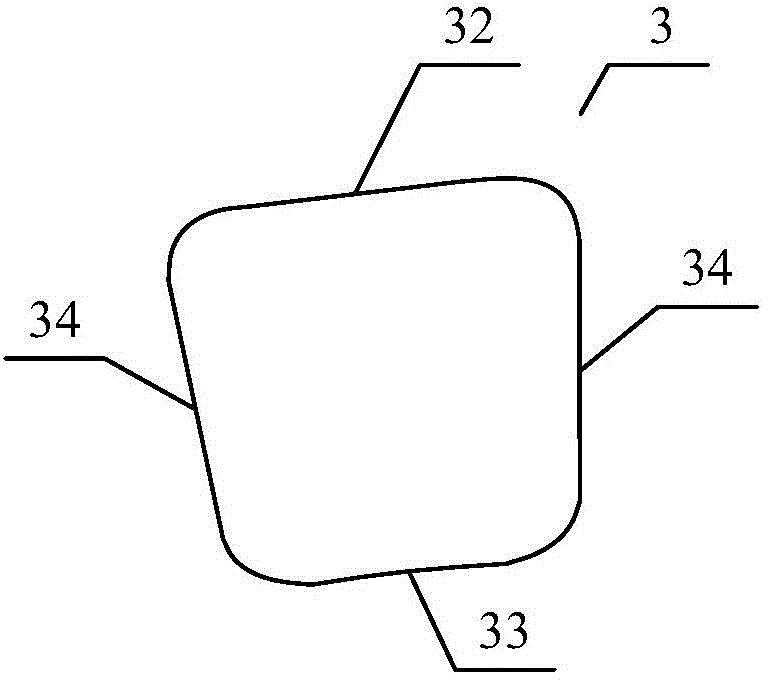

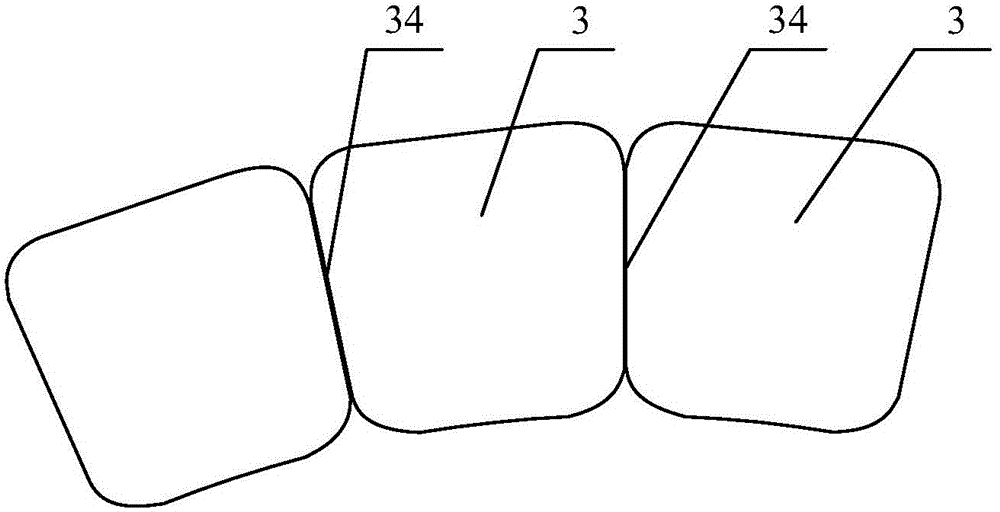

[0048] The diameter-expanding support tube 1 is a corrugated tube, and the material of the conductive single wire 3 constituting the conductive layer 2 is a heat-resistant aluminum alloy with a conductivity of 60% IACS. The cross-section of the conductive single wire 3 is S-shaped or Z-shaped, and the conductive single wire 3 is 30 Roots, and evenly and tightly twisted on the outer periphery of the expanding support tube 1, such as Figure 4 shown.

Embodiment 2

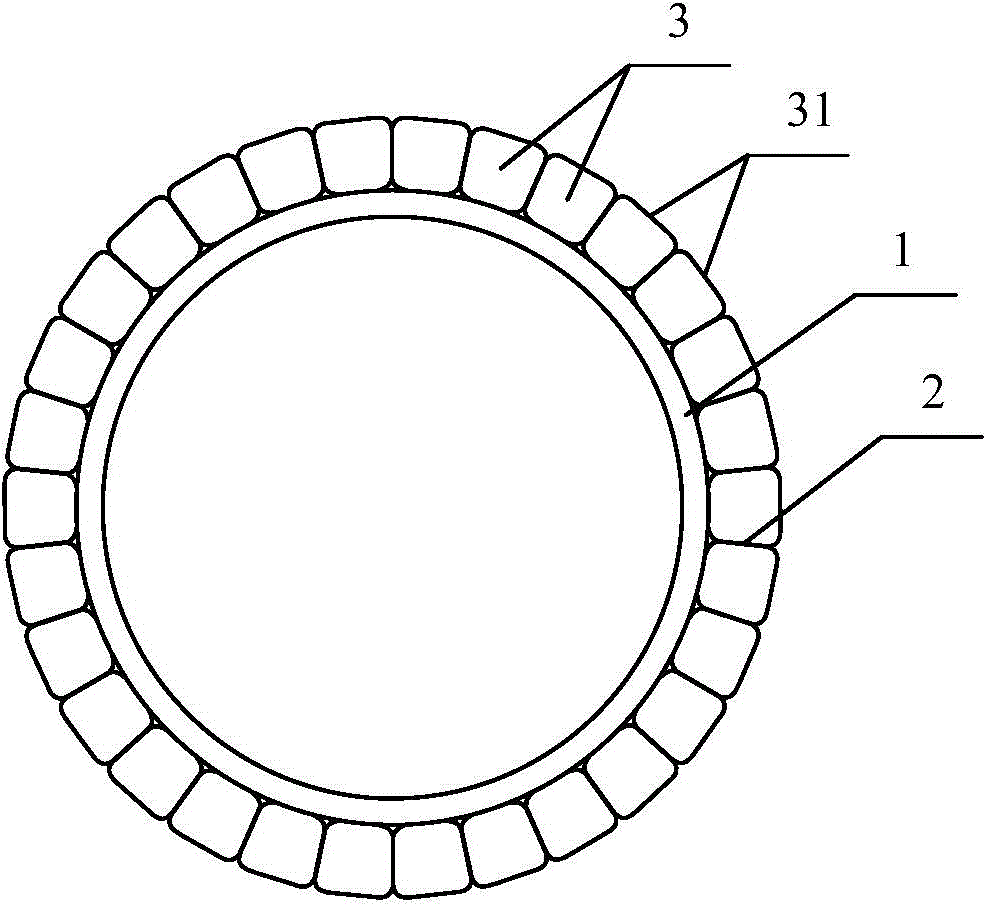

[0050] The diameter-expanding support tube 1 is a corrugated tube, and the material of the conductive single wire 3 constituting the conductive layer 2 is heat-resistant aluminum alloy with a conductivity of 60% IACS. The cross section of the conductive single wire 3 is trapezoidal, and the conductive single wire 3 is 30, and the uniform , tightly twisted on the outer periphery of the expanded diameter support tube 1, such as figure 1 shown.

Embodiment 3

[0052] The diameter-expanding support tube 1 is a corrugated tube, and the material of the conductive single wire 3 constituting the conductive layer 2 is a heat-resistant aluminum alloy with a conductivity of 55% IACS. The cross-section of the conductive single wire 3 is S-shaped or Z-shaped, and the conductive single wire 3 is 30 Roots, and evenly and tightly twisted on the outer periphery of the expanding support tube 1, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com