Method and system for evaluating object

An object, area technology, applied in the field of automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

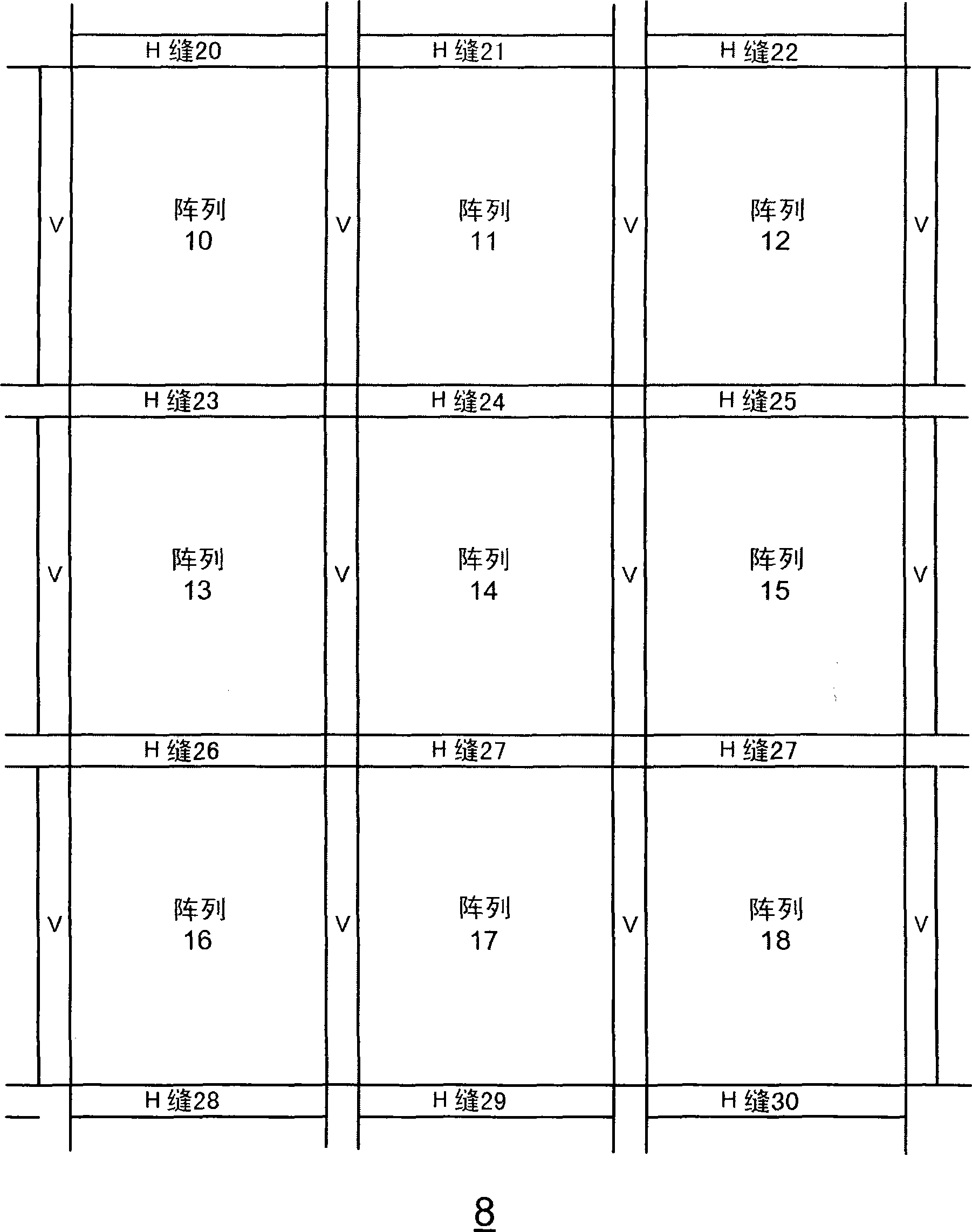

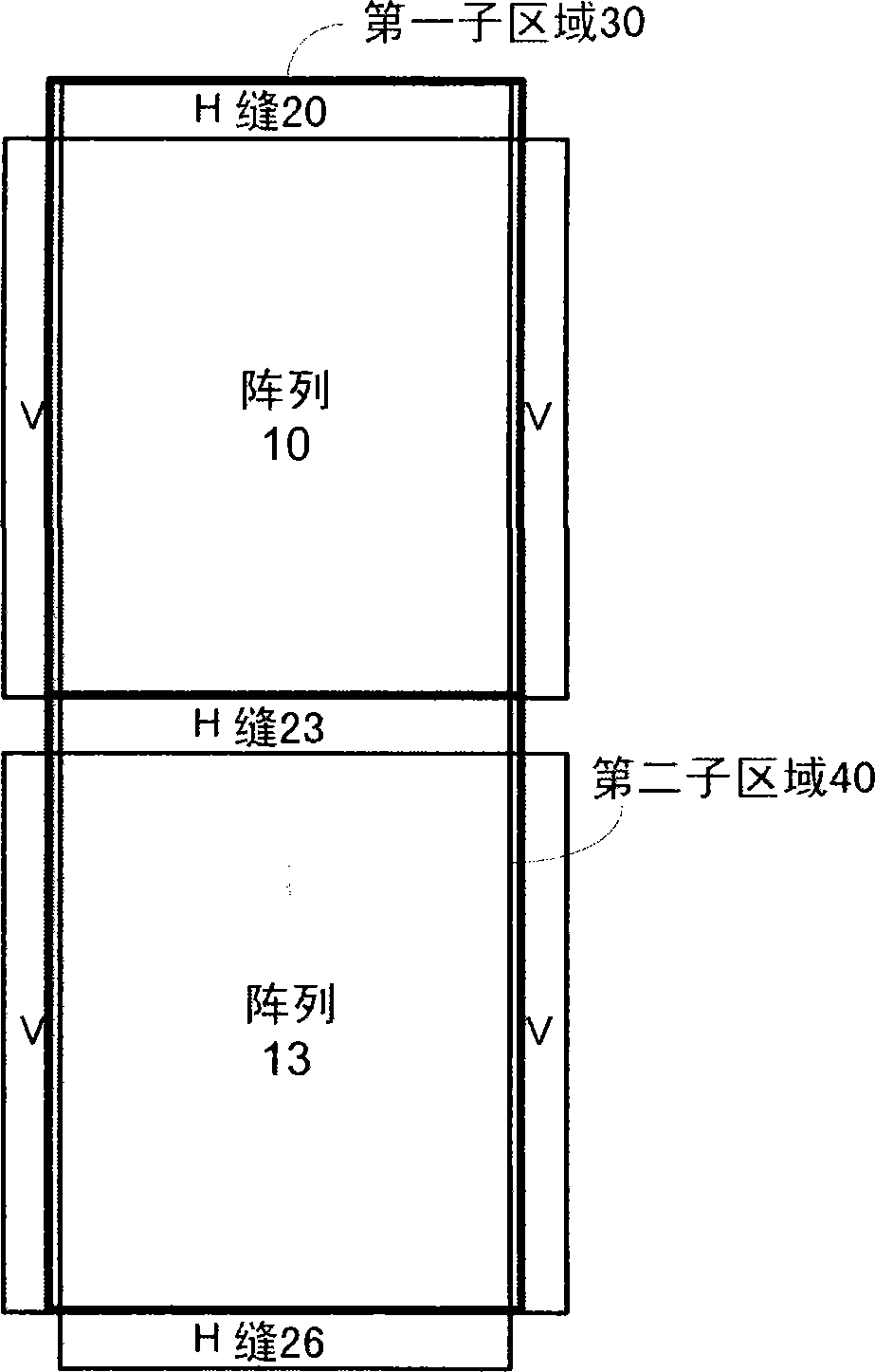

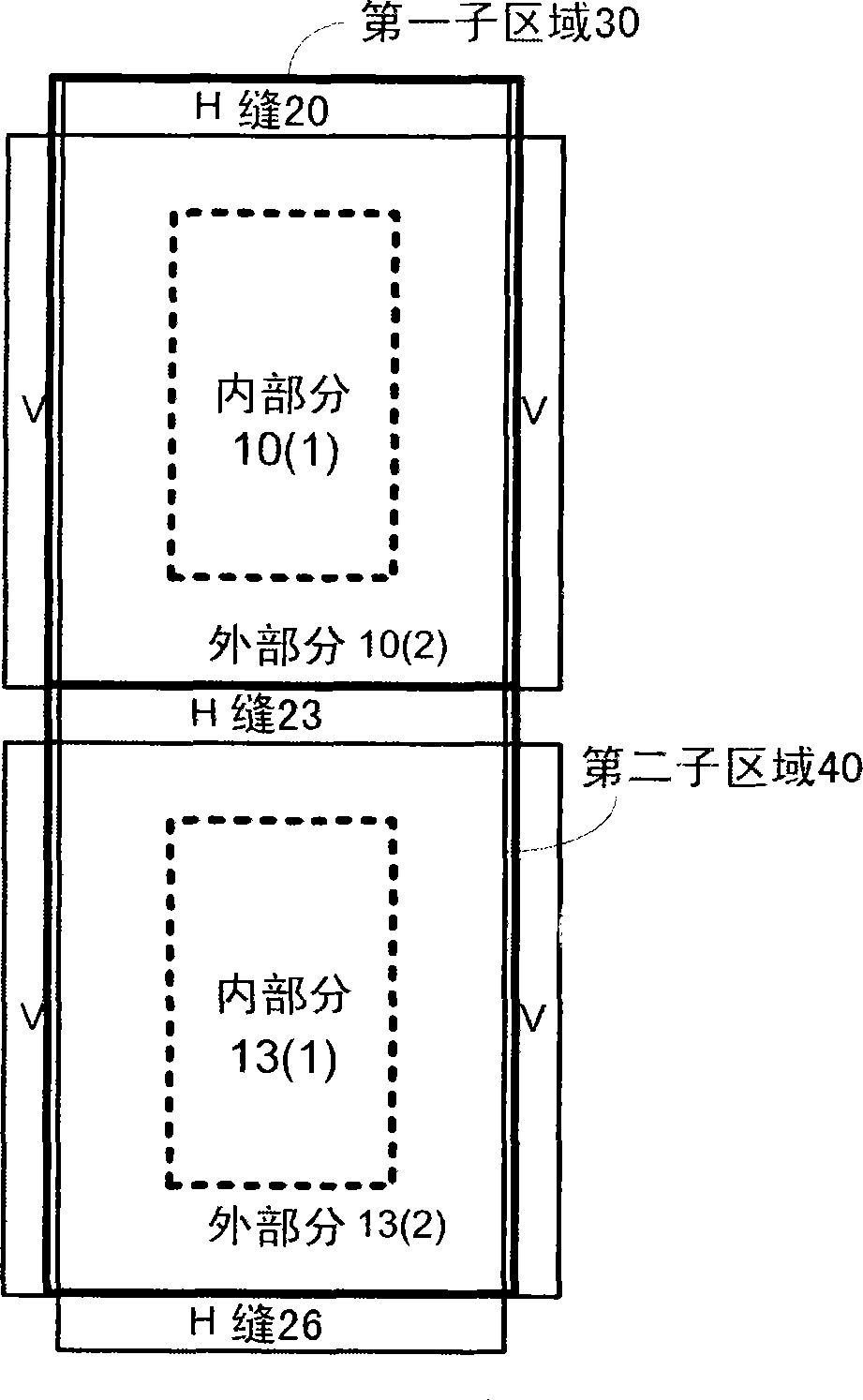

[0024] A method, system, and computer program product for evaluating objects, such as wafers, masks, or reticles, during or after fabrication for micromachining, flat panel displays, microelectromechanical (MEM) devices, and the like.

[0025] According to an embodiment of the invention sub-regions are defined. Each sub-region includes a repeating array of structural elements. The repeating array of structural elements is surrounded by at least one set of non-repeating regions. Non-repeating regions belonging to a single set of non-repeating regions are ideally identical to each other. Non-repeating regions are arranged in a repeating fashion. Instead of chip-to-chip comparisons, the methods, systems and computer program products apply other comparisons. This comparison is performed between image information of multiple non-overlapping regions belonging to subregions immediately adjacent to each other (usually belonging to the same chip). This type of comparison is more re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com