Test weight method of lifting ladle for large steel-making casting bridged crane

A technology of bridge cranes and cranes, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., which can solve the problems of high difficulty and high cost, and achieve the effects of simple operation, low cost of measures, and simple trial weight process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

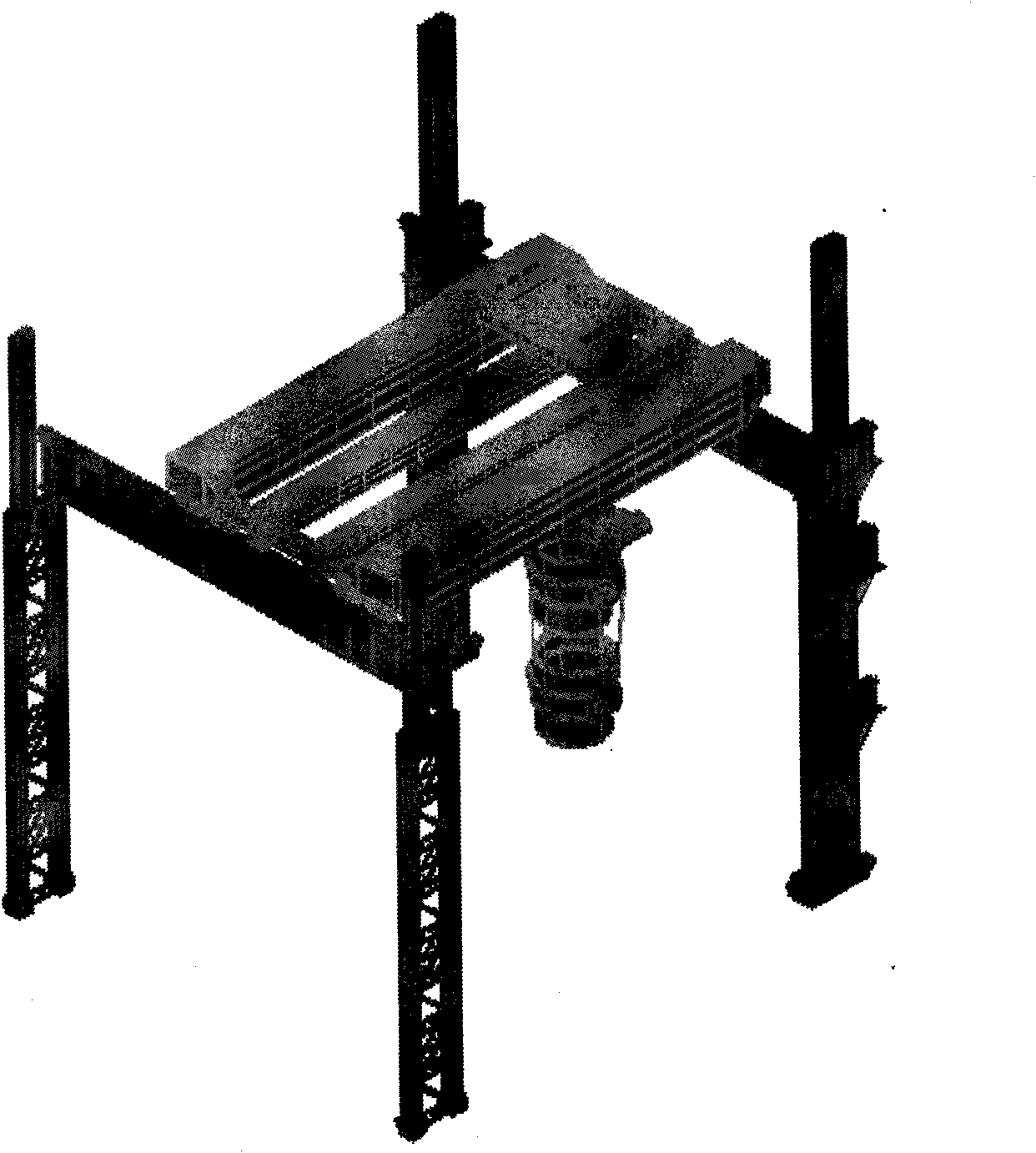

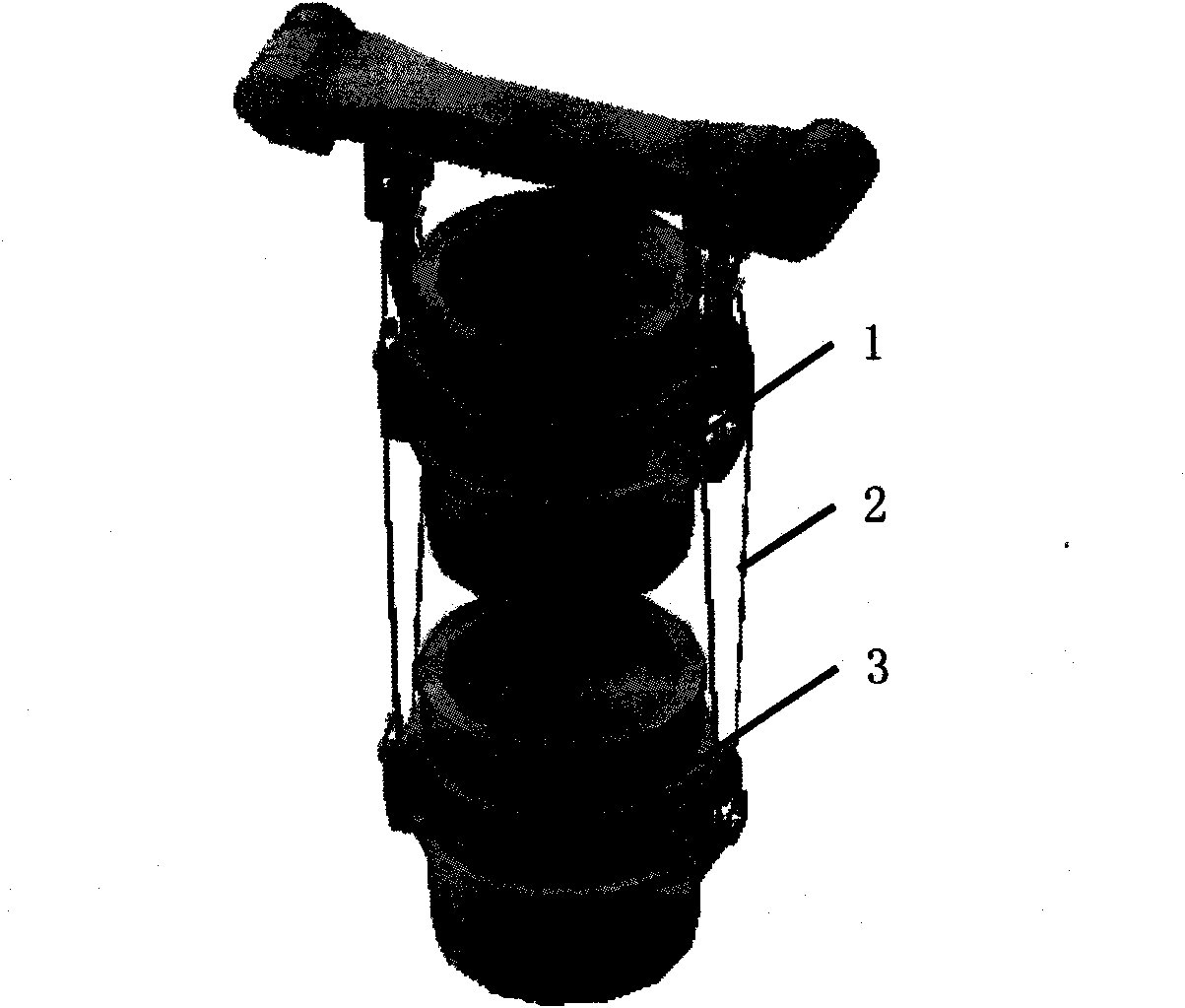

[0024] The steel-making large-scale foundry bridge crane lifts the steel ladle test weighing method in accordance with the following steps:

[0025] Step 1: Determine the number of ladles and the weight of iron in each ladle

[0026] Weigh out the weight of the steel ladle with a weighbridge, measure the actual size of the steel ladle on site, calculate the capacity of the steel ladle, and determine the number of steel ladles to be used according to the requirements of 1, 1.1, and 1.25 times the rated load of the crane test weight. Calculate and determine the weight of iron blocks to be loaded in each ladle (need to consider the gap between iron blocks).

[0027] Step 2: Preparation of counterweight

[0028] Prepare the iron block according to the requirements calculated in the first step, put the iron block into the ladle with an electromagnetic crane, and record the tonnage on the ladle, including the self-weight of the ladle.

[0029] Step 3: Inspection before crane trial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com