Method for quickly measuring blade of large-sized water turbine

A measurement method and technology of water turbines, which are applied to measurement devices, instruments, optical devices, etc., can solve the problems of small measurement range, no detection system, and inconvenience, so as to reduce measurement costs, high measurement efficiency, and improve detection speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0052] A rapid detection method for the size and profile of large turbine blades:

[0053] The placement of the turbine blades. Due to the large volume of the turbine blades and the thin wall thickness at some positions, the free placement will bring certain deformation and affect the measurement results. Visual measurements, on the other hand, require taking pictures of the measured object from different positions, so the placement of the blades needs to be considered. Follow the principles: first, it is convenient for taking pictures; second, it will not cause deformation, so it is convenient for on-site operation and improves efficiency. can be processed as figure 1 The base of the blade measurement. The base can be reused.

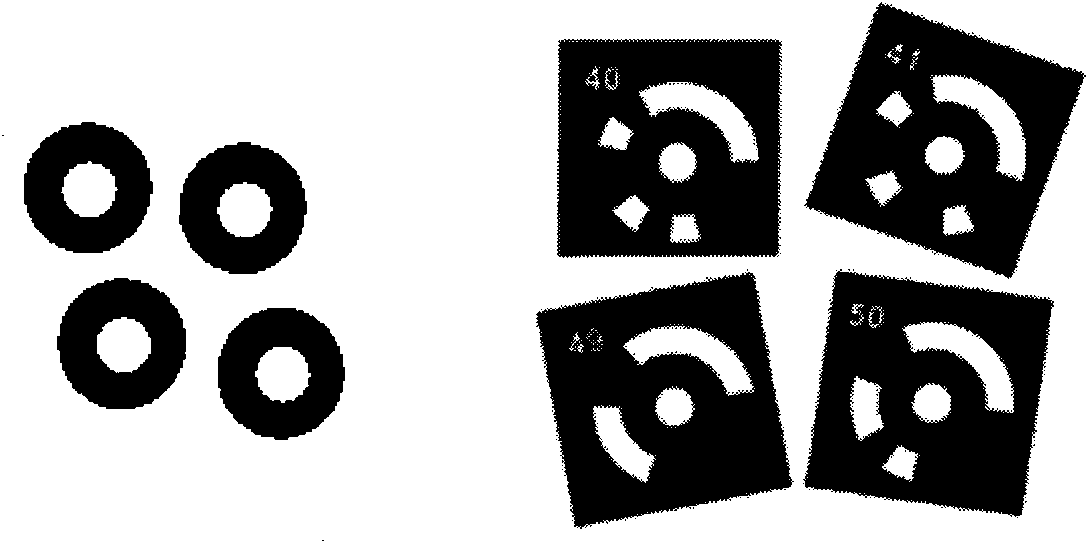

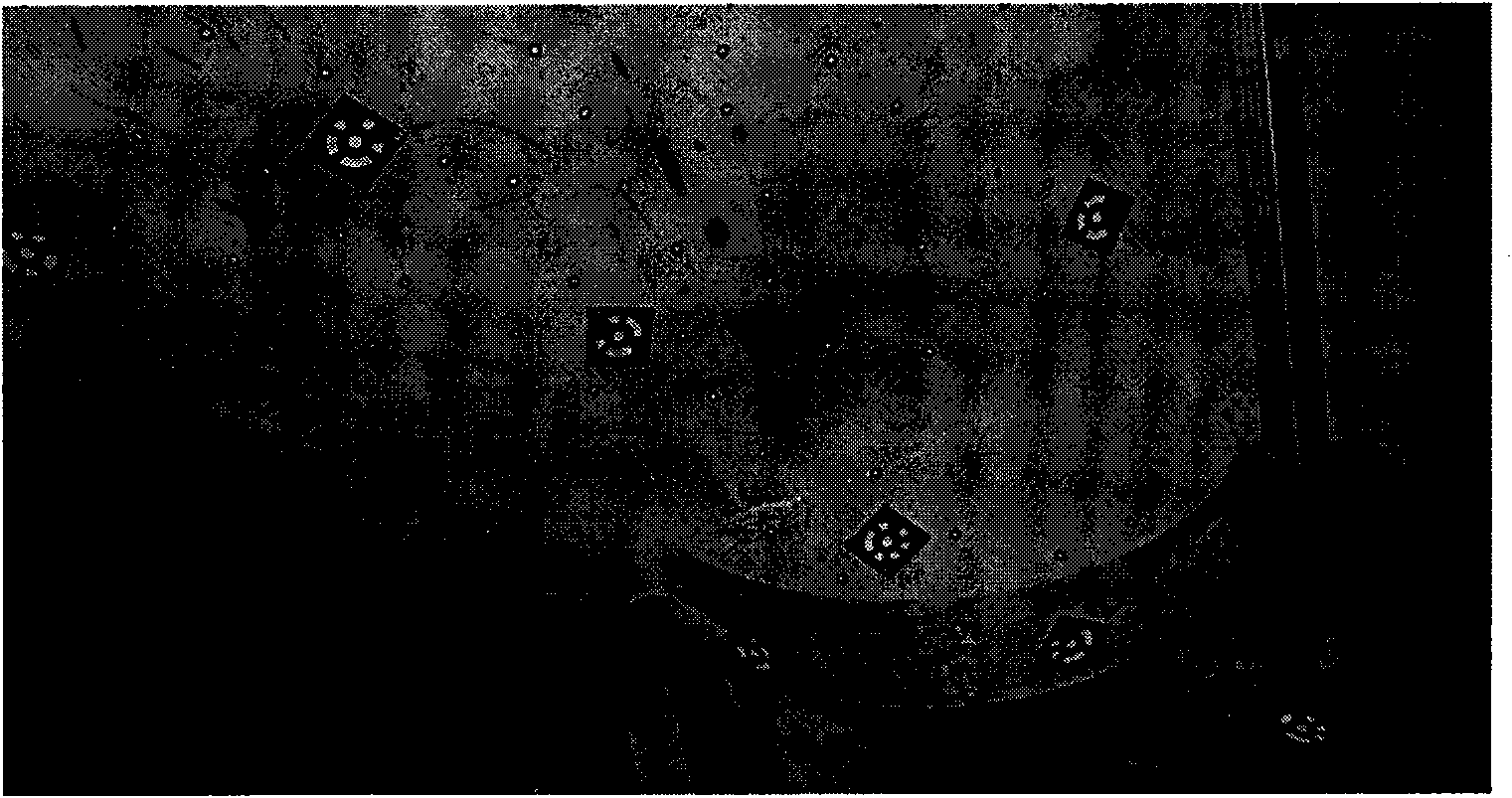

[0054] Step 1: Arrange marking points on and around the blade surface. Marker points include coded points and n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com