Sintered soaking plate and manufacturing method thereof

A manufacturing method and technology of soaking plate, which are applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of excessive contact thermal resistance between the capillary structure and the inner surface of the shell, obstruction of steam flow in the support structure, and high machining costs. , to achieve the effect of being conducive to effective diffusion, solving the increasing heat flux density, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

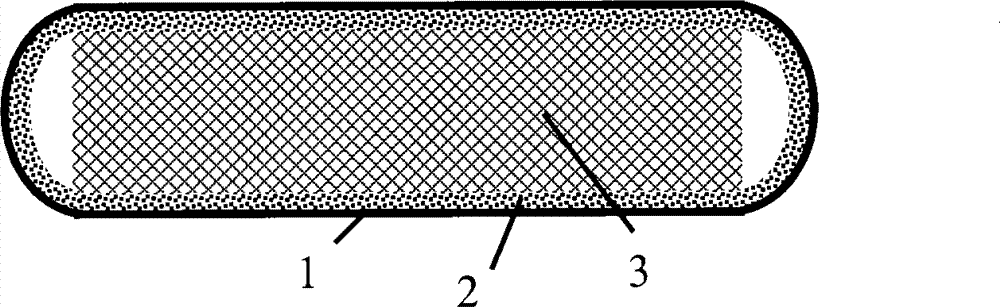

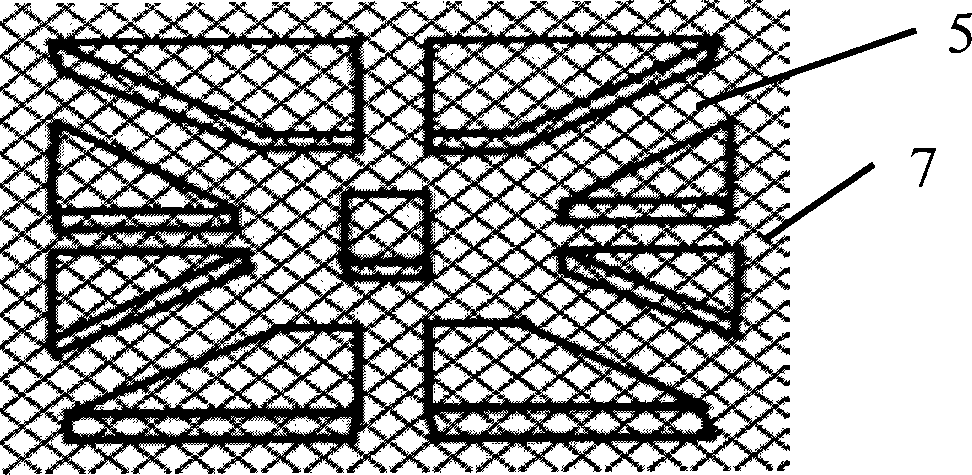

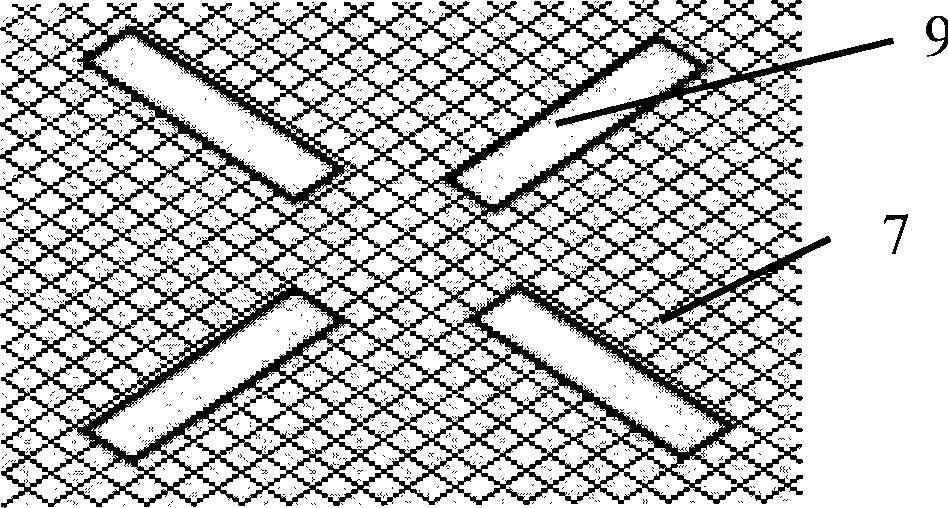

[0041] like figure 1 The shown sintered vapor chamber includes a flattened airtight casing 1 , a porous capillary structure 2 , a stamped supporting structure 3 and a working fluid filled in the airtight casing 1 . The porous capillary structure 2 is formed by sintering metal powder on the inner wall of the airtight casing 1, and the metal powder is copper powder, aluminum powder, nickel powder or nano-carbon powder. The support structure 3 is placed in the airtight casing 1, and the protruding part of the support structure 3 is in contact with the inner wall of the airtight casing 1 to support the airtight casing 1. The material of the airtight casing 1 is elastic 1. A metal material with high thermal conductivity can be copper, copper alloy, aluminum, aluminum alloy or stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com