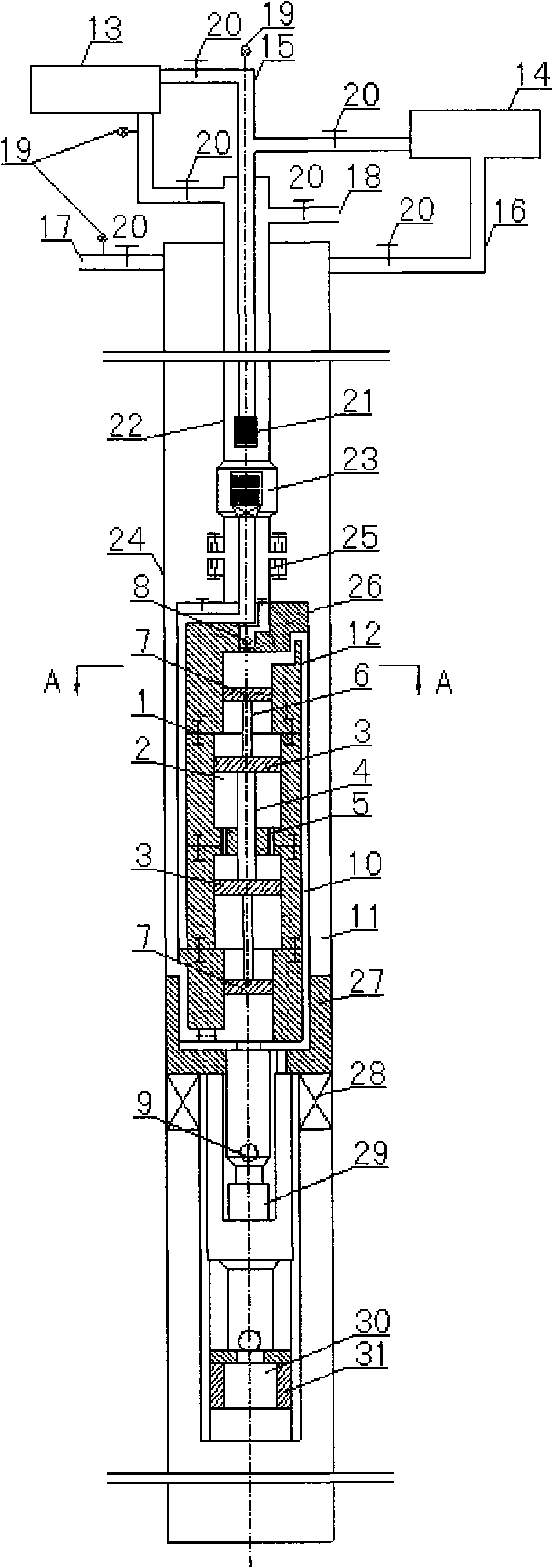

[0003] The object of the present invention is to provide a deep well gas injection supercharged mechanical oil

recovery method and device for improving deep oil

recovery, which solves the problem of insufficient

lifting capacity of existing mechanical oil

recovery methods and devices. Pressure

oil production device, the device includes gas

injection pump, oil

pipe, casing, seal seat, booster

oil production pump, pump card frame, packer, filter

pipe valve and filter

pipe, casing is sleeved on the outside of oil pipe, and on the oil pipe A sealing seat, a pressurized oil production pump, a pump holder, a packer, a filter pipe valve and a filter pipe are arranged in sequence, a switchable sliding sleeve is arranged on the oil pipe under the sealing seat, and a gas injection pipe is arranged inside the oil pipe. The end of the gas injection pipe is provided with a stop valve plug, the gas injection pipe is connected to the sealing seat through the stop valve plug, the gas

injection pump is connected with the intake pipe of the booster oil production pump through the valve, pipeline and gas injection pipe, and the

waste gas recovery tank is connected through the valve and pipeline Connected with the annular space between the tubing and the casing, the

booster pump includes a cylinder liner, a cylinder cavity, a

piston, a

piston connecting rod, a connecting rod seal

assembly, a

plunger, a plunger connecting rod, a fixed valve, and an oil

inlet valve And the oil outlet valve, the oil outlet valve is set on the top of the booster oil production pump, and the fixed valve and the oil

inlet valve are set at the bottom of the booster oil recovery pump. The inner cavity is provided with a plunger and a

piston, the plunger is connected to the piston through the plunger connecting rod, the piston is connected to the piston through the piston connecting rod, and the inner cavity of the cylinder is connected to the intake pipeline and the exhaust pipeline through the intake valve and the

exhaust valve. The inner chamber of the plunger is connected with the oil inlet pipeline and the oil pipe through the fixed valve, the oil

inlet valve and the oil outlet valve. The pipe valve and the filter pipe are connected to the oil pipe, put the oil pipe into the casing of the

wellbore, and then clamp the pump clamp; fill the oil pipe with liquid, open the valve next to the pressure relief port, and close the other valves at the same time, and pump the pump to the oil pipe and the casing. Inject liquid into the annular space between them for pressure test,

record the maximum value of the pressure gauge, relieve the pressure on the casing, then open the valve next to the liquid outlet to relieve the pressure on the oil pipe, close the valve below the air

injection pump, and connect a stop valve from the oil pipe The gas injection pipe of the plug is lowered into the well; every time it descends 600-700m, open the valve below the gas injection pump, inject gas into the annular space between the oil pipe and the gas injection pipe,

discharge the liquid from the gas injection pipe, and pass through the valve on the left of the

waste gas recovery tank Enter the

exhaust gas recovery tank, when the stop valve plug is lowered to a position one meter away from the sealing seat, and the fluid discharged from the

exhaust gas recovery tank is all gas, insert the stop valve plug into the sealing seat, and open the channel of the sealing seat after pressurization ;Close the valve on the left and below the

exhaust gas recovery tank, open the valve below the gas injection pump, inject gas into the annular space between the oil pipe and the gas injection pipe, pressurize and test the sealing effect between the stop valve plug and the sealing seat; install the

wellhead equipment, open the valve on the right side of the gas injection pump to inject gas into the gas injection pipe, open the valves next to the pressure relief port and the liquid outlet, take samples and analyze from the pressure relief port and liquid outlet respectively,

record the value of the pressure gauge, and adjust the pumped

gas pressure and Gas volume; close the valve next to the pressure relief port, open the valve on the right side of the gas injection pump and under the

waste gas recovery tank, let the circulating gas be pumped into the gas injection pipe again, open the valve next to the pressure relief port and under the waste gas recovery tank, and sample Analyze gas

humidity and

oil content, calculate production

Login to View More

Login to View More  Login to View More

Login to View More