Maize straw pretreatment method

A corn stalk and pretreatment technology, which is applied in the production and fermentation of bulk chemicals, can solve the problems of pollution, unfriendly reagents, mixed environment with impurities, etc., and achieve the effect of improving the sugar yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take the whole corn stalk as raw material, take 5g and put it into the reaction kettle. The operating conditions are: temperature 50℃, pressure 10MPa, CO 2 The amount is 100 times the amount of raw materials, the amount of water is 50 times the amount of raw materials, and the reaction time is 5 hours. After pretreatment, the solid material saccharification analysis showed that the straw sugar yield was 58%, and the lignin removal rate was 30%.

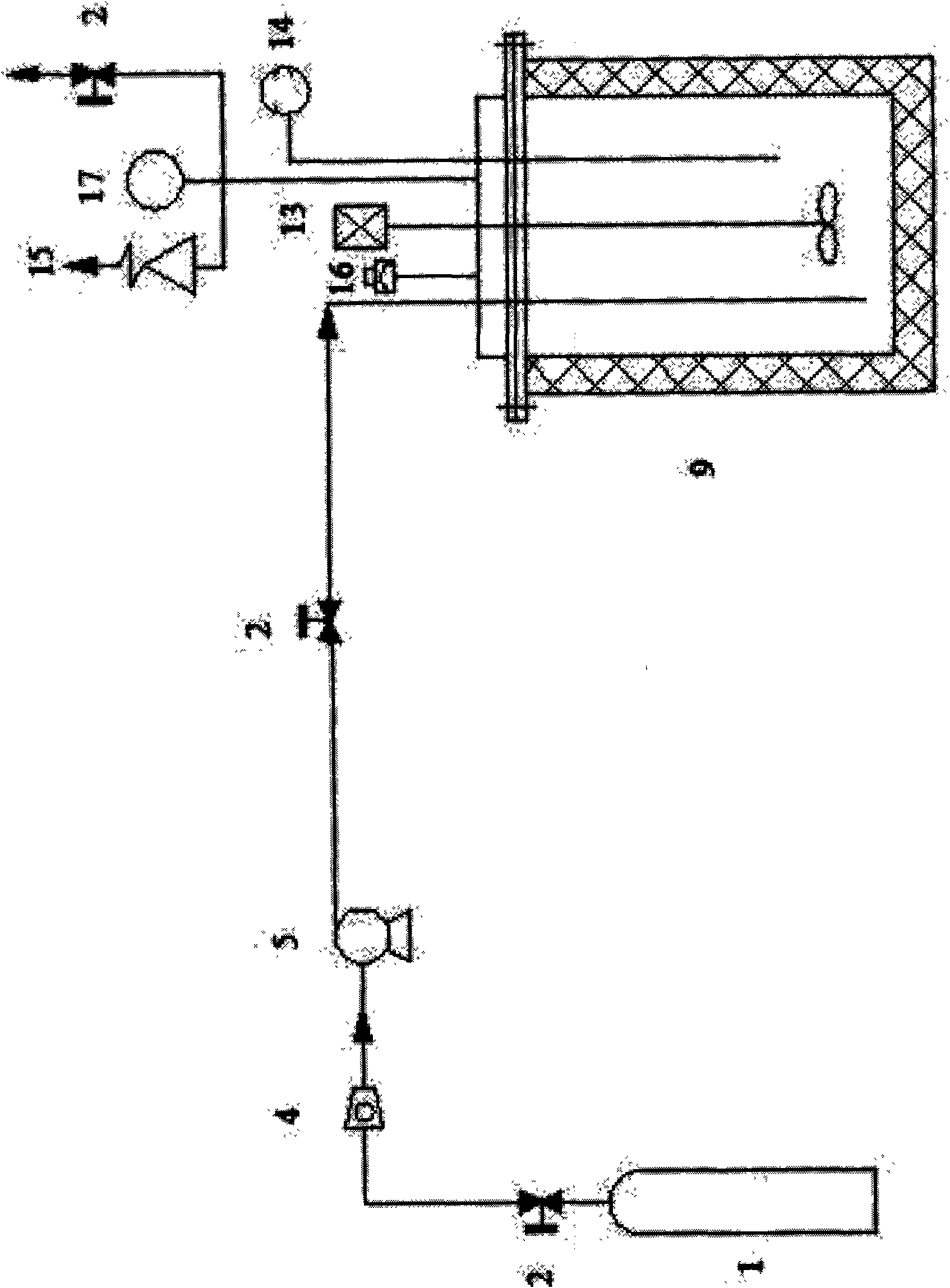

[0042] This embodiment adopts figure 1 The process shown, using CO 2 The steps for pretreating corn stover with water as a supercritical or subcritical solvent are as follows:

[0043] (1) Weigh 5g of crushed and air-dried corn stalks and 250ml of distilled water, add them to the reactor 9, and turn on the reactor;

[0044] (2) Turn on CO 2 Feed pump 5, pump 500g of CO into the reactor2 ;

[0045] (3) After the air intake is completed, turn on the main power of the controller, the power of the display, and the power of the magneti...

Embodiment 2

[0048] Take the whole corn stalks as raw materials, take 5 g and put it into the reaction kettle, and 200 ml of butanol and aqueous solution, in which the butanol content is 33%. The operating conditions are: temperature 180℃, pressure 15MPa, CO 2 The amount is 40 times the amount of raw materials, and the reaction time is 1 hour. After pretreatment, the solid material saccharification analysis showed that the sugar yield rate of straw was 95%. The lignin removal rate is 90%.

[0049] This embodiment adopts figure 1 The process shown, using CO 2 The steps of pretreating corn stover with and butanol aqueous solution as a supercritical or subcritical solvent are as follows:

[0050] (1) Weigh 5g of crushed and air-dried corn stalks, 200ml of distilled water and butanol in a volume ratio of 2:1, add them to reactor 9, and turn on the reactor;

[0051] (2) Turn on CO 2 Feed pump 5, pump 200g CO into the reactor 2 ;

[0052] (3) After the air intake is completed, turn on the main powe...

Embodiment 3

[0055] Take whole corn stalks as raw materials, take 5 g and put it into the reaction kettle. The operating conditions are: temperature 250℃, pressure 20MPa, CO 2 The amount is 40 times the amount of raw materials, and the reaction time is 0.1 hour. After pretreatment, the solid material saccharification analysis showed that the straw sugar yield rate was 40%, and the lignin removal rate was 60%.

[0056] This embodiment adopts figure 1 The process shown, using CO 2 The steps for pretreating corn stover as a supercritical or subcritical solvent are as follows:

[0057] (1) Weigh 5g of crushed and air-dried corn stalks, add it to the reactor 9, and turn on the reactor;

[0058] (2) Turn on CO 2 Feed pump 5, pump 200g CO into the reactor 2 ;

[0059] (3) After the air intake is completed, turn on the main power of the controller, the power of the display, and the power of the magnetic stirrer in turn, adjust the speed of the stirrer to 300 rpm, and set the reaction temperature;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com